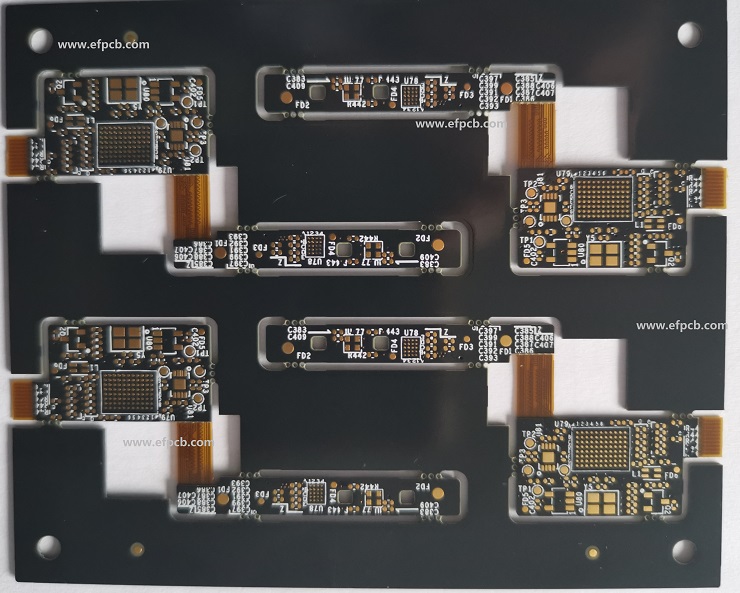

Know About Rigid Flex PCB Fabrication Technology

Keywords: Rigid Flex PCB, Rigid Flexible PCB Manufacturer

A broad flood has been found in the inescapability of versatile printed circuit sheets and Rigid Flex PCB development recently. This is a result of its advantages in the creating wearable contraptions industry

Space hold reserves and decreased weight are introduced by Flex and inflexible flex PCB development. With rigid flex development, minimal lightweight purchaser equipment are a large part of the time gathered today. In any case, in productive rigid flex PCB plan, there can be numerous challenges. In partner electronic parts in various non-buyer and client devices, both versatile and rigid versatile printed circuit sheets (PCBs) expect a critical part. As indicated by the name, a rigid PCB is just a circuit board in view of a layer of an unyielding base that can't wind. On a versatile base fit for imploding, bending, and bowing, a versatile PCB likewise called a flex circuit is manufactured. For pleasant warm hindrance and parts, phenomenal assistance is introduced by an inflexible circuit board.

The fundamental progression example of as of late developed equipment things incorporates high steady quality, 3D social gathering, and downsizing as indicated by the state of the art contraptions things' improvement design. Concerning scale and development, generally speaking PCBs update persistently. This is a result of the expansion of the equipment market. From that point on, for researching different advances reasonable with the example of progress referred to above, printed circuit board makers have been trying. Versatile PCB setup shows up considering the limitations on applications and the environment. In this way, flex-unyielding PCB was bound to ensure the 3D social affair limit and welding capacity of equipment things moreover.

Inflexible flex PCB's Fabrication development stays aware of persistently growing movement of things and overhauling with advancement headway. Window creation is seen as a middle in much the same way as key production development of flex-rigid PCB is concerned. counting methodologies for hindrance stick, laser cutting, copper foil scratching, window opening, negative as well as specific significance control and filling strategy, driving window creation headways of flex-unyielding PCB is sorted out in this article.

Window Opening Method of Rigid Flex PCB

The cycle where advantage of mechanical handling or shape punching is taken by unyielding flex PCB from Rigid Flexible PCB Manufacturer with a middle board structure for killing rigid focus in no-stream prepreg and a versatile part is Window opening technique. This is to work with the period of flex-unyielding PCB through overlay.

Cover Layer Coating

After overall and close by covering, X-region assessment is executed on through blind through. Thusly, it is contemplated that delamination issues can be squashed by the local covering development as a result of the mistake of electrical conductivity and warm effect so the constancy of the thing will be updated.

PE Punching for Flexible Portion

Ensuing to collecting the cover layer, PE punching should be executed as changes will happen on versatile board size during overlay of the cover layer to update layer plan.

No-Flow PP Window Manufacturing

To the extent that different piece counts and different creators, no-stream PP concrete flood aggregate can be attempted with practical cover process considered and considering IPC-TM-650 test guidelines. Levelness can be ensured at the association purpose in flex-unyielding PCB after compensation arrangement is finished on the main client's window.

Window Manufacturing at Rigid Portion

For clearing out unyielding focus reasonable with versatile piece, shape punching or mechanical handling should be used. While mechanical works on handling on low or mid-volume creation, Mold punching works better on mass-volume creation.

Copper Foil Etching Method of Rigid Flex PCB

The cycle wherein the advantage of plans is taken by rigid flex PCB with a copper foil structure is Copper foil drawing. In this cycle, the window at the versatile piece is revealed.

Cover

During cover, makes manageable strain is gotten by the external copper foil on PCB by the execution of a phenomenal overlay design structure. This occurs considering the different coefficients of warm expansion inferred for various materials. As such, very few issues like dreadful board surface levelness, copper foil hurt as well as crimps, and awful PP concrete filling can be squashed.

Window Etching

After power running with a copper-plated board is done, Negative scratching is finished. With versatile board revealed, copper foil at versatile part should be cut away.

Filling Method of Rigid Flex PCB

The cycle wherein surface piece, as well as fillers, will be killed through blind handling and fillers are put at the window of flex-inflexible PCB is filling system.

Pre-stackup

Filler is placed into a hollow window during the process of stackup meeting the following requirement:

- Filler Thickness must be the same as that of filling

- Filler must be resistant to high temperature

- The filler must be smooth and soft on the surface

- Equal to the window with high stability, the filler Figure must be the same

- CTE must be lower than or equivalent to a substrate material

Molding

By applying mechanical processing, Window at the detached situation at flex-unbending PCB is manufactured and mechanical profundity controlled is utilized to create the window at the associated position. The adaptable region will be immediately uncovered as filler is taken out.

Positive and Negative Depth Control Method of Rigid Flex PCB

The cycle wherein a visually impaired groove is made ahead of time on the inflexible load up is the Positive and negative profundity control technique. The inflexible board is nearby the adaptable board. Joined with blind section, the Mechanical profundity control strategy is utilized during trim subsequent to overlaying and piling up. To make the adaptable part uncovered, an unbending board will be then dispensed with at the window position.

Blind Groove Fabrication for Rigid Flex PCB Board

The reach from 33% or two-third of that of unbending center board is utilized to normally control the profundity of inflexible visually impaired groove. To quit processing harming adaptable board, it should not surpass the scope of viable mechanical profundity control capacity. In the accompanying techniques, a visually impaired score can be produced:

Blind notch by X-beam: To manufacture blind furrows in associated openings, a Carbon dioxide x-beam machine is utilized.

Mechanical processing blind section: By applying a computerized controlled processing machine, a Blind depression is produced.

V-cut blind notch: By applying a V-cut machine, a V-cut blind furrow is fabricated.

Blind notch by laser cutting: by applying an UV laser cutting machine, the Blind furrow is cut.

Key advances of Rigid Flex PCB creation have been presented by this article. For a few sorts of unbending flex PCB, window producing and different techniques work. To add to amazing execution and high unwavering quality of flex-unbending PCB, every one of the techniques can be applied agreeably.