Know About a Chip on PCB Board

Keywords: IC Substrates, IC Substrate PCB

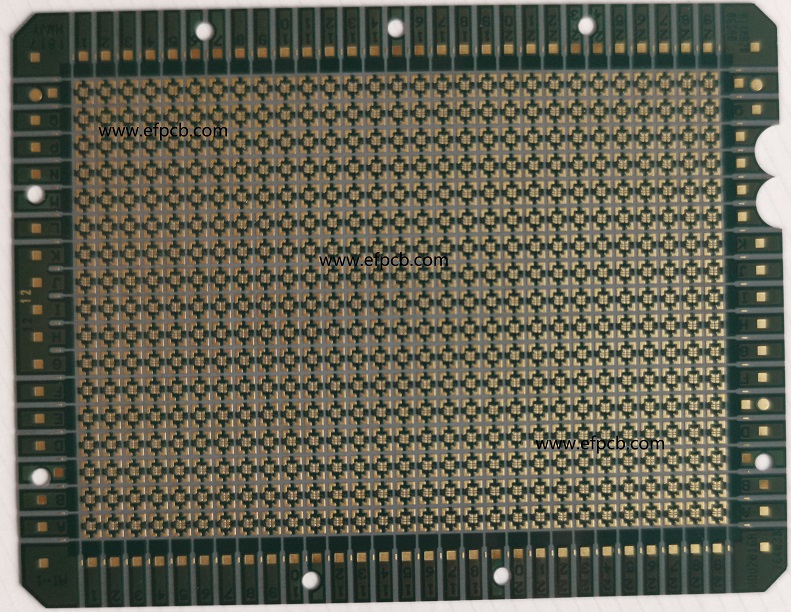

The semiconductor IC Substrates is first attached to the PCB via the COB. It is a semi-exposed Chip on Board IC. The next step is to attach the wire to the PCB's surface. The technique of putting bare semiconductors on a PCB chip or substrate using conductive or nonconductive epoxy is known as a chip-on-board assembly. For electrical connections, chip-on-board IC often employs gold ball bonding or aluminum wedge bonding. We offer a range of semi-sintered epoxy resins that may be utilized for chip-on-board assembly for applications that demand extremely high thermal and electrical conductivity.

Additionally, flip-chip technology, which connects the chip face down to the PCB using pre-applied solder balls at the wafer level or our internal bumping process, is available to PCB makers.

Adhesives are used in IC Substrate PCB technology to adhere semiconductor chips to the PCB substrate. It is then packed by a wire connecting it to an existing circuit layout on the board. Chip on board pushes the boundaries of surface mount technology (SMT). The primary distinction between COB (chip on board) and SMT is that COB typically comprises active devices with a high lead count and does not call for ceramic or molded plastic exterior device packaging.

On-board Dialysis Application

A chip put directly on the PCB is said to be a "chip on board." Use a ball of epoxy or plastic to cover the chip once the wires are connected. The board is attached to and wire-bonded to the bare PCB chip, and epoxy resin is injected into it to protect and insulate it.

A laminate substrate and signal conditioning or support circuits are used to install an unpackaged integrated circuit (IC). An electrical connection is created when the IC is joined to the matching substrate connector via gold wire bonding. The chip and wire bonds can then be shielded by putting a junction coating material on top of the chip.

On the one hand, a chip on a board's key benefit is that it improves the circuit's weight and quality. Chip-on-board technology is the best option for miniaturizing your circuit when this is a big problem.

Additionally, system designers have unique assembly possibilities because to chip on board technology.

Benefits and characteristics of IC Substrates on board:

- both high and low pressures

- specific coating

- double-sided, with many layers

- Test of a functional board

- Low or high volume

- wide range of temperatures

- Competitively priced approach

- Turnkey software