Job of High-Power PCB in High Temperature Climate

Keywords: High Temperature PCB, High Temperature PCB Manufacturer

As the commonest parts coordinated stage, the job of multi-facet PCBs is to interface circuit sheets and parts together parts have become exceptionally coordinated, prompting the high trustworthiness and High Temperature PCB with electronic items turning out to be light, dainty and little in size, and having elite execution. Because of this, the intensity creation has expanded and the warm thickness of PCBs has progressively gone up particularly because of the mass use of high-recurrence IC parts, for example, A/D or D/A sort.

The dependability of electronic hardware will be incredibly affected assuming huge warm misfortune neglects to be conveyed. The disappointment pace of electronic parts will increment dramatically with the expansion in temperature. The disappointment pace of a few electronic parts can increment to two times enormous once the climate temperature increments by 10°C. In this way, focusing on warm plan during the planning of PCB is significant.

With the reason examination, the investigation needs to initiate. In the presence of force utilization parts, the immediate reason for the high temperature of PCBs lies. To an alternate degree, every part has a power utilization that excites the adjustment of warm strength. There are two sorts of temperature expanding peculiarities: neighborhood temperature increasing which is a huge region temperature climbing and momentary temperature increasing. There are three different ways of intensity move: heat conduction, heat convection, and intensity radiation. High Temperature PCB Producer additionally gives incredible assistance.

Through electromagnetic wave movement going through space, radiation disseminates heat. As the radiation dissemination includes a somewhat low measure of intensity, it is then viewed as a helped dispersal strategy.

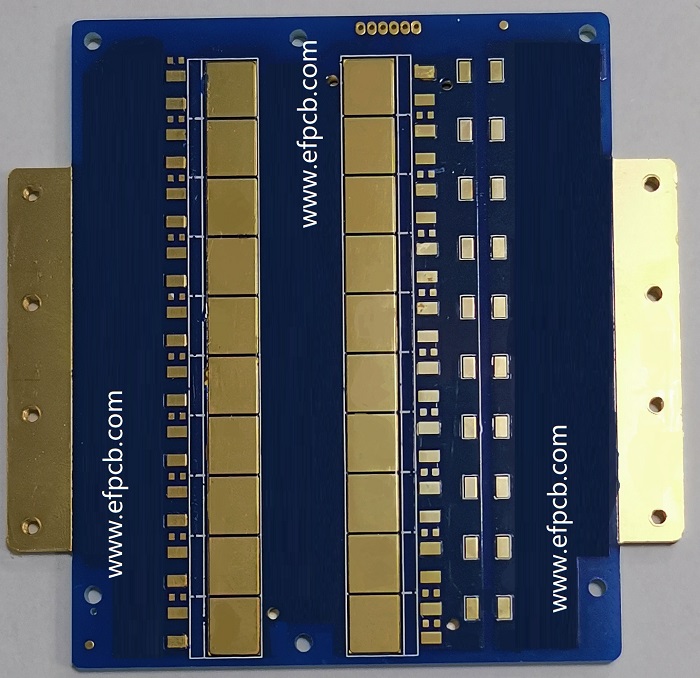

The significant material of metal center PCB covers aluminum, copper, and steel. It could actually be utilized as the ground layer. Through the plated opening the upper layer and lower layer of the metal center PCB can be interconnected and the intensity is then moved to the internal layer and surface of the metal center PCB.

On the board through the base and intensity conduction opening warming components can be straightforwardly patched. Subsequently, in metal center PCB the intensity produced by warming components is straightforwardly moved that then, at that point, communicates the intensity to the digression case by the intensity conduction opening and sends it out. High Temperature PCB with such a design has a wide series of uses however they can likewise bring about certain issues.