Innovative Electronic Design of Flexible PCB

Keywords: Flexible PCB, Flexible PCB Manufacturer

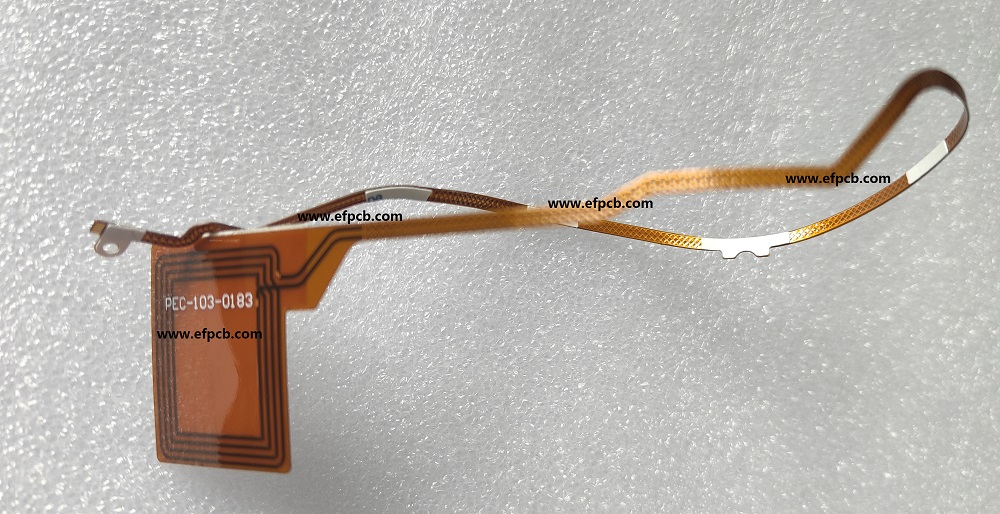

Adaptable printed circuit sheets, or Adaptable PCB, are a kind of electronic circuit board that can be bowed, collapsed, contorted, or even moved up without losing their usefulness. These sheets are made utilizing different adaptable materials, for example, polyimide, polyester, or slim film that permit them to be molded into a large number of plans and applications.

Flexible PCBs have various purposes in present day hardware, including cell phones, wearables, clinical gadgets, and car gadgets. They offer a few benefits over customary inflexible PCBs, including further developed plan adaptability, lower weight and thickness, expanded strength, and decreased get together and creation costs.

In this blog, we'll investigate the different sorts of adaptable PCBs, their benefits and impediments, and their applications.

Kinds of Adaptable PCBs

There are a few kinds of adaptable PCBs, including single-sided, twofold sided, multi-facet, and unbending flex.

Single-Sided Adaptable PCBs

Single-sided adaptable PCBs are the least difficult and most savvy sort of adaptable PCB. They comprise of a solitary layer of adaptable material, commonly polyimide, with a flimsy layer of copper conductive material scratched onto one side. The parts and interconnections are put on a similar side of the board.

Twofold Sided Adaptable PCBs

Twofold sided adaptable PCBs have conductive material on the two sides of the board, taking in to account more parts and interconnections to be put on the board. These sheets are more perplexing and costly than single-sided adaptable PCBs however offer more plan adaptability.

Multi-facet Adaptable PCBs

Multi-facet adaptable PCBs comprise of numerous layers of adaptable material with conductive material scratched onto each layer. The layers are reinforced together utilizing glue or warm holding strategies. These sheets are more mind boggling and costly than single-sided and twofold sided adaptable PCBs yet offer expanded plan adaptability and higher part thickness.

Unbending Flex PCBs

Unbending flex PCBs join the advantages of inflexible and adaptable PCBs, with both unbending and adaptable materials being utilized on a similar board. These blocks are made of a mix of adaptable and inflexible layers with copper conductive material carved onto the outer layer of both. Unbending flex PCBs offer expanded plan adaptability and are regularly utilized in applications where an elevated degree of toughness and unwavering quality is required.

Benefits of Adaptable PCBs

Adaptable PCBs offer a few benefits over customary unbending PCBs, including:

Further developed Plan Adaptability

Adaptable PCBs can be planned in many shapes and sizes, considering more prominent plan adaptability. This is particularly valuable in applications where space is restricted, or sporadic shapes are required.

Lower Weight and Thickness

Adaptable PCBs are lighter and more slender than customary unbending PCBs, making them ideal for use in compact gadgets, for example, cell phones and tablets.

Expanded Sturdiness

Adaptable PCBs are sturdier than customary unbending PCBs, as they can endure bowing, turning, and vibration without breaking or breaking. This makes them ideal for use in applications where an elevated degree of unwavering quality is required.

Diminished Gathering and Creation Expenses

Adaptable PCBs can be fabricated utilizing computerized get together procedures, which diminishes the requirement for difficult work and brings down creation costs. They likewise require less material than unbending PCBs, further decreasing creation costs.

Challenges in Adaptable PCBs

While adaptable PCBs offer a few benefits over conventional unbending PCBs, they likewise have a couple of difficulties, including:

Greater expense

Adaptable PCBs are more costly to make than conventional unbending PCBs, because of the specific materials and assembling processes required.

Restricted Part Thickness

Adaptable PCBs have a lower part thickness than customary unbending PCBs, implying that less parts can be put on the board.

Higher Intricacy

Adaptable PCBs are for the most part more intricate to plan and make than customary unbending PCBs. This is because of the requirement for particular materials, producing cycles, and plan contemplations, which can add to the general intricacy and cost of the board.

Restricted Temperature Resistance

Adaptable PCBs have restricted temperature resistance, which can restrict their utilization in high-temperature applications. This is because of the materials utilized in the board, which can be harmed or debased at high temperatures.

Uses of Adaptable PCBs

Adaptable PCBs have a great many applications in current hardware, including:

Cell phones

Adaptable PCBs are regularly utilized in cell phones, for example, cell phones and tablets, because of their lightweight and meager plan. They are utilized to associate and control the different parts in the gadget, including the presentation, battery, and processor.

Wearables

Adaptable PCBs are additionally generally utilized in wearable gadgets, for example, smartwatches and wellness trackers. They are utilized to control and interface the different sensors and parts in the gadget, for example, the pulse screen, GPS, and show.

Clinical Gadgets

Adaptable PCBs are utilized in a scope of clinical gadgets, including pacemakers, defibrillators, and glucose screens. They are utilized to control and screen the different elements of the gadget, and their adaptability makes them ideal for use in implantable gadgets.

Auto Gadgets

Adaptable PCBs are likewise utilized in car gadgets, including motor control units, airbag sensors, and route frameworks. They are utilized to control and associate the different parts in the vehicle and their adaptability makes them ideal for use in auto applications.

Assembling of Adaptable PCBs

The assembling system utilized by Adaptable PCB Producer for adaptable PCBs is like that of conventional unbending PCBs, with a couple of key contrasts. The means are:

Plan

The most important phase in assembling an adaptable PCB is to plan the board utilizing particular programming. The plan should consider the exceptional properties of adaptable PCBs, including the curve sweep, material properties, and part situation.

Printing

When the plan is finished, it is imprinted onto a substrate material utilizing a particular printing process. The substrate material is normally a polyimide or polyester film that can be formed and bowed into the ideal shape.

Carving

Subsequent to printing, the board is carved to eliminate abundance copper and make the ideal follows and circuits. This interaction is like that of conventional inflexible PCBs.

Penetrating

Then, the board is penetrated to make openings for parts and connectors. The penetrating system should consider the one of a kind properties of the adaptable material and the requirement for the openings to be situated precisely.

Plating

Subsequent to penetrating, the board is plated with a dainty layer of metal, commonly copper, to make a surface for binding parts.

Gathering

At last, the parts are gathered onto the board, and the board is tried for usefulness and solidness. This cycle should consider the special properties of the adaptable PCB, including the requirement for legitimate part arrangement and strength.

End

Adaptable PCB offers a few benefits over conventional inflexible PCBs, including further developed plan adaptability, lower weight and thickness, expanded toughness, and decreased get together and creation costs. They are utilized in a large number of utilizations, including cell phones, wearables, clinical gadgets, and car hardware.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6IC Substrate | Comprehensive Guide (2021)

- 7Top 10 Flexible PCB Factories in 2025

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact