IC Substrate PCB: An Intriguing Theme to Be aware of

Keywords; IC Substrates, IC Substrates China

With the blasting of new sorts of ICs like CSP (chip scale bundle) and BGA (ball matrix cluster), IC substrate has been creating. This needs new bundle transporters. In the two applications and ubiquity together, IC Substrates PCB has detonated with any layer flex-unbending PCB and HDI PCB as one kind of the most developed PCB (Printed Circuit Board). These are applied in gadgets and media communications refreshes.

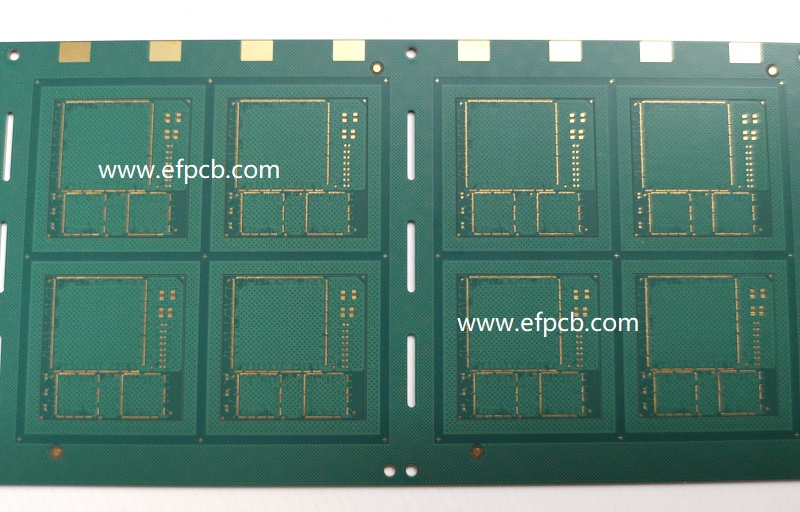

IC Substrates

Used in the bundling of uncovered coordinated circuit chips, IC substrate is a baseboard type. The substrate IC demonstrates significant in associating the circuit board and the chip. Effectively catching semiconductor coordinated circuit chip, directing to interface the chip with the PCB, as well as building up, supporting, and protecting the IC chip, incorporated circuits fall under a momentary item. It offers a passage for warm dissemination as well.

As connectors of the printed circuit sheets to the semiconductor chip, incorporated circuit substrate assumes an essential part. It assumes the part of a channel. To give interconnect densities that outperform those of PCB fabricators, it requires limit on IC fabricators during the assembling system of IC substrate. In synthetic skill with respect to high-thickness plans, makers will require a have demonstrated arrangements and specialty thus.

Used to bundle exposed IC (incorporate circuit) chip, IC substrate is a sort of baseboard. IC has a place with a middle item with the accompanying capabilities Interfacing circuit board and chip:

• Semiconductor IC chip is caught by it;

• For interfacing PCB and chip, there's directing inside;

• Giving warm scattering burrow, it can uphold, build up and safeguard IC chip.

Under various orders Coordinated circuit substrates fall and they are particularly different. We will take a gander at the different sorts under each class and every order to grasp the entirety of this better.

IC Substrates Arrangements

Class according to Bundle credits

• BGA IC Substrate: In electrical execution and warm scattering, this sort of IC Substrate performs well. This can increment chip sticks emphatically. Thusly for an IC bundle with a pin count surpassing 300, it is reasonable.

• CSP IC Substrate: With the scaled down scale and lightweight, CSP is a kind of single-chip bundle. This highlights a comparable size to IC. In electronic items, media transmission items, and memory items with few pins, CSP IC substrate is predominantly utilized.

• FC IC Substrate: Highlighting viable warm scattering, low circuit misfortune, low sign impedance, and very much performed execution, FC (Flip Chip) is a sort of bundle by flipping chip.

MCM IC Substrate: Multi-chip module or MCM is a kind of IC Substrates China. Chips with various capabilities are ingested into one bundle. Because of its credits including scaling down, slenderness, daintiness, and brevity, the item can be an ideal arrangement subsequently. Normally, this kind of substrate doesn't perform so well in fine steering, warm dispersal, signal impedance, and so forth as numerous chips are bundled into one bundle.

Classification according to material ascribes

• Inflexible IC Substrate: It is made by ABF pitch, BT sap, or epoxy tar fundamentally. Its warm extension coefficient is roughly 13 to 17ppm/°C.

• Flex IC Substrate: It includes a warm extension coefficient of 13 to 27ppm/°C and is fundamentally made by PE tar or PI.

• Clay IC Substrate: By fired materials like silicon carbide, Aluminum nitride, or Aluminum oxide, it is basically made. Roughly being 6 to 8ppm/°C, It includes a somewhat low warm extension coefficient.

Classification according to holding innovation credits

• FC Holding

• TAB (Tape Robotized Holding)

• Wire Holding

IC Substrate PCB Applications

On electronic items having progressed capabilities, slenderness, and lightweight like tablet PC, PC, cell phones and organization in fields of clinical consideration, media communications, military, aviation, and modern control, IC substrate PCBs are applied chiefly.

From substrate-like PCB, customary HDI PCBs, and multi-facet PCB to IC substrate PCBs, Inflexible PCBs have completely finished a progression of developments. With a comparable manufacture process roughly semiconductor scale, SLP is only a kind of inflexible PCBs.

Producing Interaction of IC Substrate PCB

Between the IC chip and a printed circuit board, incorporated circuit substrate goes about as the essential association. By the organization of conductive openings and follows, it achieves this.

Fabricating Steps

• Copper designing and plating: In the assembling system, this is the initial step. Corresponding to different mechanical viewpoints like control and circuit pay innovation, scarce difference manufacture innovation, and uniform control of copper plating thickness, it includes the platting tech and copper designing.

• Patch veil: It follows the copper plating and designing cycle. Patch cover printing and opening filling advancements are available in the bind veil for coordinated circuit substrate PCB. Among cushion and patch cover, under ten-micrometer level distinction of substrate have been allowed by IC substrate PCBs reliably. Nonetheless, permitting in excess of fifteen micrometers isn't suggested.

• Surface wrapping up: Guaranteeing a uniform thickness of the surface completion is significant in this step. The utilization of ENIG and ENEPIG surface completions is involved, which are adequate in all cases.

• Unwavering quality tests and Examination: This is the last step of IC substrate producing. For quality as well as dependability, the incorporated circuit substrate needs to get examined here. Nonetheless, from those used in standard printed circuit sheets, the innovation utilized in the review and testing dependability varies.

In any case, in spite of the means identified above, understanding that the assembling system of coordinated circuit substrate PCB isn't direct is fundamental.

IC Bundling

It frequently comes as the Last Move toward semiconductor gadgets creation. At this stage, a packaging shielding the incorporated circuit from age-related consumption or unfavorable outer components is gotten by the semiconductor. The packaging by configuration safeguards the block separated from advancing electrical contacts. This conveys signs to an electronic gadget's circuit board.

From the BGA bundles of the 1970s, The IC bundling tech developed when they became famous among the makers of electronic bundling. Notwithstanding, from the beginning of the 21st century the fresher choices and adaptations eclipsed pin lattice exhibit bundles. In such advancements the plastic quad level pack and little slender diagram bundles are incorporated. At present like the FCBGA, further developed bundling advancements exist. It is an up-degree of the land framework exhibit bundles.

Last Touch

For connecting the IC chip and PCB, IC substrates are significant in hardware. At the point when it is the question of a broken or fruitful IC plan for your electronic application, understanding every little thing about them can turn into the distinction because of this. Consequently while planning your IC Substrates for an improved result, you should consider the viewpoints examined.