IC Packaging: Everything That You Were Unaware of

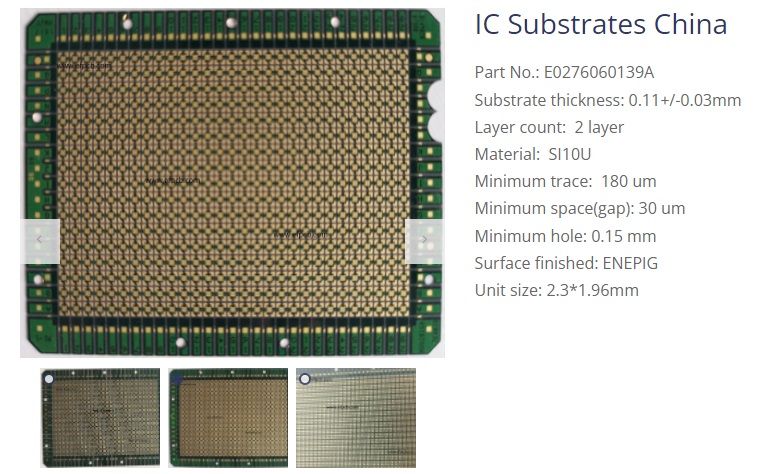

Keywords: IC Substrates, IC Substrates China

The world of electronics is ruled by IC Substrates China. Either in integrated or discrete form, Electronic components are available. For standalone components only like an inductor, diode, transistor, capacitor, or resistor, the discrete form is reserved. Electronics were made so popular by the ICs actually and it is ubiquitous today. All sorts of circuits like mixed, digital, and analog -signals, and all components types like active or passive can be integrated into an IC. That may not use any IC, You may find very few commercial circuits.

The ICs are interconnected and assembled on a prototyping board or a printed circuit board together with other discrete components to produce a functioning electronic circuit. In a variety of packaging, electronic components come. A lot of things are decided by the packaging. If the component can be used on a PCB, prototyping board, or both is the first one. Normally in multiple IC packages, electronic components are available to suit different phases of product development (like production and prototyping) and suit different considerations of circuit design. When it has to be used on a PCB, The packaging of an IC gets important really.

There are different ways of classifying these package types and many different types of IC packages. Some basics of IC packaging will be discussed in this article.

IC packaging

The encasing of a semiconductor component refers to Integrated Circuit Packaging. Semiconductor wafers that are layered in a complex formation with other materials and copper are the core of any IC. A die is then formed and cut mash-up of these semiconductor wafers. Fabricated at a microscopic level, the die has all its interconnections and components. Macroscopic electrical contacts are taken out from the die in the final stage of IC production. So with other components on a PCB, the integrated circuit can connect. The IC packaging is all about taking out macroscopic electrical contacts for interconnections on a PCB and encasing the semiconductor die.

Significance of IC packaging

As the integrated circuit, the packaging of an IC Substrates is as important as the semiconductor device within. Three purposes are majorly served by the packaging – first from physical damage or impairment, it protects the semiconductor circuit. Secondly from corrosion, it protects the circuit. It decides how from the semiconductor device over a PCB, electrical contacts are laid out finally and crucially. For both PCB designing as well as IC designing, this is an important consideration. With the various use cases and applications of the respective IC, how they are laid out using a standard IC package must be coherent like how the connections are organized in an IC.

Which Stage needs IC Packaging?

Typically, the last production stage of semiconductor devices is IC packaging. Hence, in an enclosure, the semiconductor component gets protected at this stage. And one thing is enclosed in this package. From possibly damaging the external elements, it shields the IC. Plus from corrosion, it also protects it.

An encasement is the enclosure package. For protecting the device block, it’s responsible. And promoting vital components also helps. The electrical contacts are one of such. To the PCB of an electronic appliance, these components help to carry signals.

Classification of IC packages

First of all, according to their mounting style, IC packages can be classified. One of the obvious distinguishing factors in ICs is mounting style. Into two broad categories, All IC packages fall by mounting style – surface-mount (SMT) and through-hole (PTH). Before soldering, the IC leads are designed to be inserted through holes on the PCB In through-hole packages. With printed circuit boards having tracks on inner layers and both sides, PTH was introduced to work. Through-hole packages are easy to work with and bigger. Prototyping boards and breadboards as well these can be used. Through-hole is still used in commercial circuits wherever surface-mount is not suitable though surface-mount technology succeeded in plated through-hole (PTH). For example, with transformers, inductors, and heat sinks, through-hole mounting is ideal for semiconductor components.

The component is mounted directly on the exterior of the PCB in surface-mount packaging. Surface-mount devices (SMD) are called the components and ICs having surface-mount packaging. Surface-Mount Technology (SMT) is a different technology. In a smaller area, SMT allows the automated placement of more components. The SMD components themselves have either no or smaller lead and have a smaller form factor. The through-hole packaging has almost been overtaken by SMT. for a few situations where through-hole is still the ideal choice; the preferred mounting is always SMT except in commercial circuits.

How the pins are laid out of the device is the second way the IC packages can be further classified. All ICs are square, rectangular, or linear in shape. The Pinout in two parallel directions can be a linear, matrix, or on all four sides form.

Their terminal (pin) shape is the third way the IC packages can be further classified. In different shapes like mutual folding, linear, J-shape, L-shape, needle shape, electrode bud, tape/film shape, and solder bud, the leads are possible.

The terminal count is A fourth way to distinguish IC packages. There are more than six-terminal IC packages, three-terminal, two-terminal, five-terminal, four-terminal, and six-terminal. As a distinguishing factor, the dimensions of the terminals also serve in similar package types

Design of IC Packaging

The best way to achieve the following is through Next-generation IC packaging design:

- Functional density

- Heterogeneous integration

- Silicon scaling

- For reducing the overall package size, it’s ideal for many applications.

Hence, heterogeneous and homogenous, IC packaging provides a path to the following:

- Faster time-to-market

- The resiliency of Silicon yield

- The enhanced functionality of the device

Today, various platforms of IC technology have emerged, and the following are met by them:

- Cost-effectiveness

- Power optimizations

- High performance

- And the needs of different industries can be satisfied like:

- High-performance computing (HPC)

- Artificial intelligence (AI)

- Medical

- Aerospace

- Mobile Computing

- IoT

- 5G

- Automotive

- Augmented reality (AR)

- Virtual reality (VR)

Every Engineer Must Avoid this Challenge of IC Package

Engineers must avoid the following when dealing with the latest IC packaging technology:

An accurate substrates aggregation since it can be active and passive at the same time.

One thing is sure the devices and substrates come from different sources. In various formats, The IC package designs will come which is tricky.

Solution

Staying abreast of the latest IC packages will help. And the designs must include and support:

- Digital prototyping

- Golden signoff

- Multi-domain integration

- Precision handoff production

- range and Scalability

Wrap Up

The importance of picking the right IC packaging can’t be stressed enough. Hence with the perfect packaging, you won’t worry about damage or corrosion to your PCB. That’s why to explain IC packaging in detail, we took the time.

So, consider these factors before you decide on the type of IC packaging you need:

- Cost

- Connectivity

- Assembly capacity

- Power

Narrowing your options to the barest minimum will be good for IC Substrates China.