Here is An Overview of Flexible PCB Build Up

Keywords: Flexible PCB, Flexible PCB Manufacturer

The possibilities of modern electronic gadgets have significantly increased thanks to the development of Flexible PCB technology. Many fragile and sensitive technological gadgets have them at the heart of their design. This technology is used by a wide variety of electronic gadgets, including your smartphone, camera, laptop, calculator, and many others.

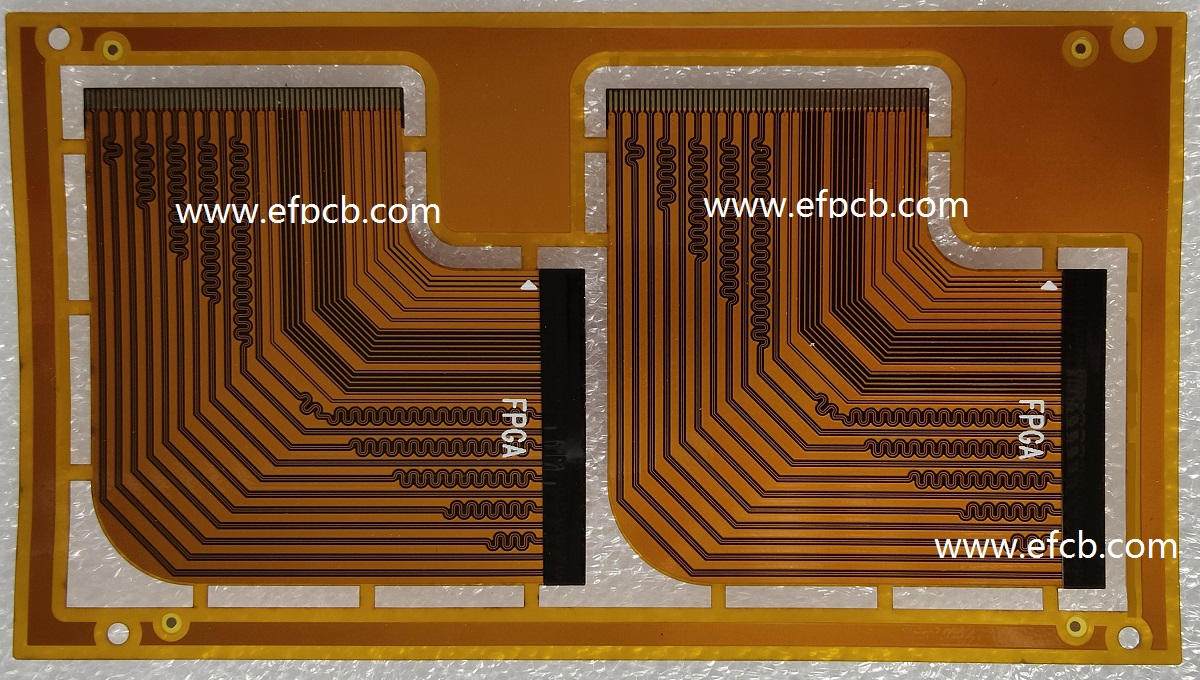

Flexible PCB

It is constructed using polyimide as the foundation substrate material. This substance, which may be found both naturally and artificially, is employed in a variety of sectors, including the automotive and apparel industries. When compared to conventional rigid printed circuit boards, flexible circuits' small size and high electrical connection density give us significant weight, space, and cost benefits. When used in the appropriate application, this technology may save the overall cost of electrical hookups by up to 70% and the amount of wiring used by up to 75%.

Flex PCB Construction

The initial phase is when the preservation of the basic material is the major objective. The primary material used for the flex circuit is polyimide.In comparison to FR-4, this material is more costly, and it must be utilized correctly. Circuits should be kept as near to one another as feasible utilizing the nesting method for proper polyimide utilization. The following procedures are used in the fabrication of prototype PCBs from Flexible PCB Manufacturer:

Looping: It's okay to add a little bit of excess content over the designer's maximum. The servicing length and circuit assembly are made possible by this additional material, sometimes referred to as a service loop.

Size of conductor: Because it offers the most flexibility, you should choose the thinnest copper possible, especially if you want to utilize the circuit for dynamic applications.

Etching: This procedure is used to make up for any isotropic losses that may have occurred during manufacture. The line width loss during this operation is approximately twice as great as the thickness of the copper foil. The line width is affected by several variables, including the conductor, various copper kinds, and etches masks.

Routing: The wires may be simply routed. Just arrange yourself so that you are parallel to the curve and fold. Lowering stress will enhance folding and bending. Create crosshatched ground regions if the electrical allotment is sufficient. Lowering the weight of the circuit board helps the circuit's flexibility.

Flexible PCB distinguishes itself from other traditional solutions by providing a diversity of connectivity and dependability.