Guide to PCB Gold Finger Manufacturer

Keywords: Gold Finger PCB, Gold Finger PCB Manufacturer

These associations are taken care of by PCB gold Finger. As innovation develops, there could be no other choice with the exception of a gold finger PCB. The need to connect devices is turning out to be more significant. Normally, the meaning of Gold Finger PCB is developing. You will find out about PCB gold fingers in the wake of perusing this post.

What are the PCB Gold Finger plan prerequisites?

These gold fingers are the associations that permit you to electrically interface the Gold Finger PCB to another PCB. The PCB is known as the Gold Finger PCB, and the associations are known as gold fingers due to their gold plating and finger-like appearance. The associations, which are arranged close to the PCB's edge and give a decent association, are there. Since the PCB might be connected straightforwardly, the technique gets rid of the requirement for link connectors. It is a more reliable, vigorous, and powerful decision.

Maybe you saw how far separated the fingers were. This is finished to ensure that associations are kept separated from each other. While planning the PCB, a few factors, for example, dividing, association count, synthetic creation, thickness, and others are considered.

A PCB's gold Finger likewise covers the plan and specs of a few other innovative devices and circuit sheets. In the event that you are endeavoring to foster an entire circuit board, the accompanying focuses will cover the plan determinations for the gold finger PCB. These spots will work on the plan of the gold Finger.

You should guarantee that the PCB's internal layer is without copper. The presence of copper in the internal coating of the PCB could cause consistent openness during slanting. During shifting, not any more light is anticipated. Subsequently, don't use copper metal in the inward layer of a PCB.

Each PCB is PTH or has through-opening plating. Also, those openings should be exactly positioned. Inside a 1mm span of the gold Finger, the PCB will not be embedded through the PCB openings. The Gold Finger and the PTH should be isolated by somewhere around 1mm.

Brilliant fingers presented an out and out new range. They frequently accompany associations that might be connected to motherboards or other related gadgets. Notwithstanding, the kind of association you make characterizes the gold method you use. In the event that you simply have to interface once, a submersion surface is a decent decision. In any case, on the off chance that you're embedding and pulling out cards routinely, the brilliant fingers should have a gold-plated finish.

The plan of the whole board might be found on the PCB. The board frame and the gold Finger should not be associated, and there should be a 0.5 mm space between the gold Finger and the board frame.

These separating rules are industry standard, and breaking them can bring about issues. To stay away from issues, the gold-plated circuit sheets should be planned by this guidance.

The printed circuit board incorporates a weld veil as well as broad screen printing, in any case, specialists and designers ought to remember that no patch cover or screen printing ought to be set close to a gold finger. It isn't proposed to utilize PCBs with screen printing or bind covers close to gold fingers from Gold

Finger PCB Manufacturer

What are the PCB gold Finger quality measures?

The PCB gold fingers' not entirely set in stone by:

• Before information is placed into a given gadget, each electronic circuit is checked. These circuit sheets are exposed to a few exhibitions and quality measures.

• The accompanying part will show you how to gauge the nature of PCB gold fingers.

• The gold plating of the PCB's gold Finger requires 5-10% cobalt.

• The Gold Finger's anticipated strength is given by a little amount of cobalt in the gold plating.

• The thickness of gold fingers is totally directed.

• The PCB gold finger width should be somewhere in the range of 2 and 50 micro inches, as per this norm.

What impact could the Brilliant Finger have on the world?

A more solid association is required. Cell phones, computers, and different contraptions are turning out to be faster and all the more remarkable as innovation propels. The worth and meaning of the PCB gold finger have developed as innovation and correspondence get more intelligent.

Gold-plated circuit sheets empower the present innovation to be however canny as it very well might be. Over the long haul, innovation proceeds to advance and turn out to be speedier. It occurred because of better gold-plated circuit sheets. The circuit board's gold Finger makes inclusion and extraction more straightforward and quicker.

The gold finger PCB's surface treatment: As a result of its higher conductivity, oxidation opposition, and wear obstruction, electroplated nickel gold is broadly used in gold finger PCBs that require consistent stopping or PCB sheets that require customary mechanical erosion. While gold plating is unquestionably costly, it is just utilized for neighborhood gold plating, like gold fingers.

Gold Submersion: The width of regular reaches from 1u" to 3u". On account of its outstanding conductivity, evenness, and weld capacity, it is habitually used in high-accuracy PCB sheets with button positions, fortified IC, BGA, etc. The total board drenching gold strategy is likewise a possibility for gold finger PCBs with insignificant wear obstruction prerequisites. The drenching gold method is altogether more affordable than the electric gold technique. The drenching gold strategy delivers a brilliant yellow color.

Factors for Gold Finger Plan

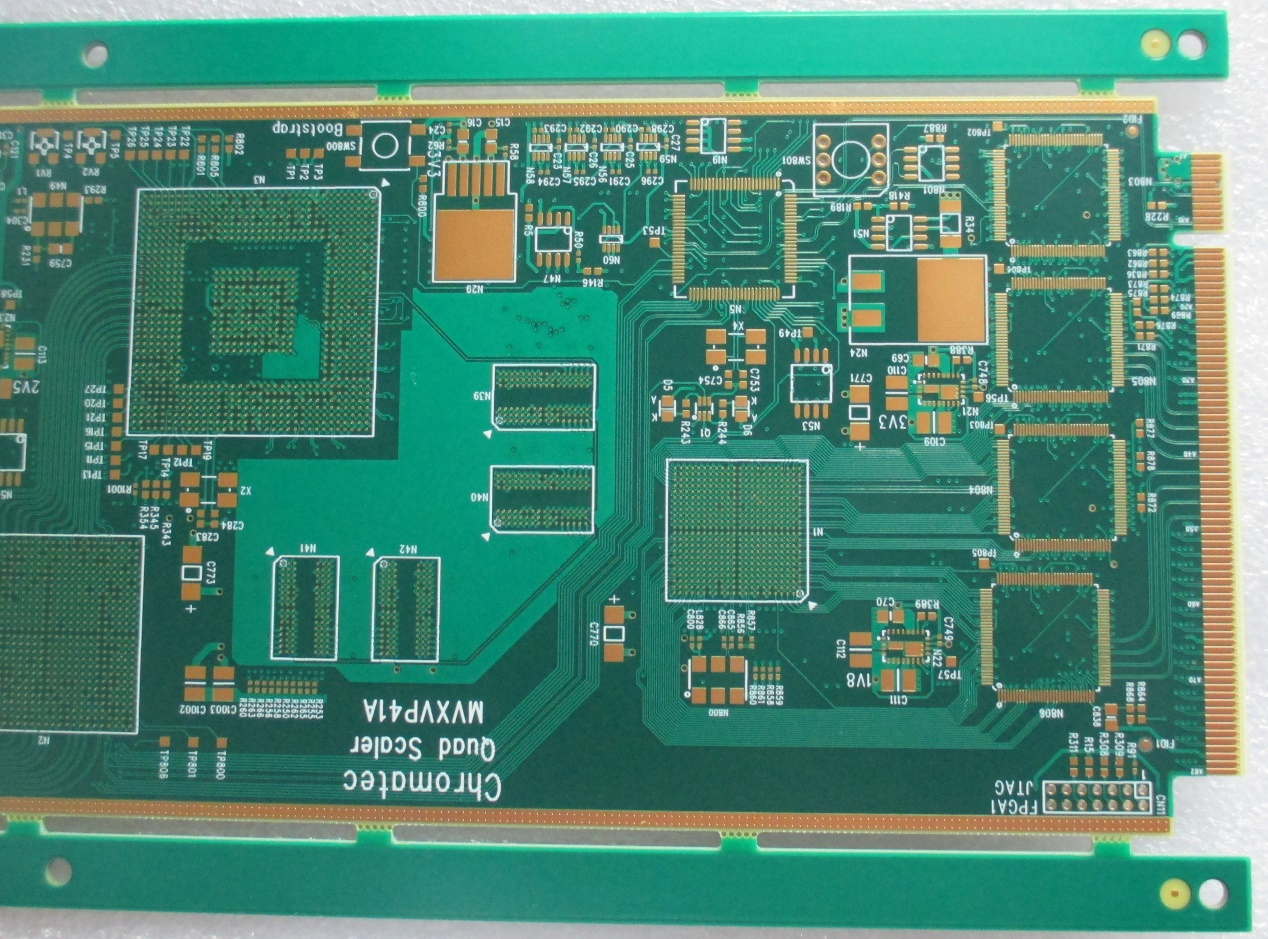

At the point when you see a structure and bundling in a PCB plan that seems to be the one underneath, your underlying idea is that the board has a gold finger. A more straightforward way for deciding the brilliant finger: both the base and top sides of the gadget will contain PIN gadgets and a u-molded groove.

At the point when gold fingers are available on the board, it is basic to dealing with the gold finger subtleties cautiously.

Gold Finger Detail Handling in PCB:

• To fortify gold fingers wearing obstruction on PCB sheets that are consistently embedded and removed, gold fingers are generally covered with hard gold.

• The gold finger should be chamfered, commonly at 45°, and at different points, for example, 20°, 30°, etc. There is a trouble in the event that the plan does exclude a chamfer.

• The gold finger should play out a total weld cover window treatment, though the PIN doesn't need to open the steel network.

• Submersion silver and Drenching tin cushion expect no less than 14 mils from the tip of the finger. It is prompted that the cushion, including the by means of cushion, be 1 mm or all the more away from the finger area.

• Never put a copper on the outer layer of a gold finger.

• Copper cutting is expected on all levels of the inward layer of the gold finger. The copper is normally 3mm wide.

The Gold Finger PCB has a lower impedance, and the copper cutting (under the finger) may decrease the impedance contrast between the impedance line and the gold finger, which is likewise helpful for ESD.