Groom up Your Insight about Gold Plating of PCB

Keywords: Hard Gold PCB, Plating Gold PCB

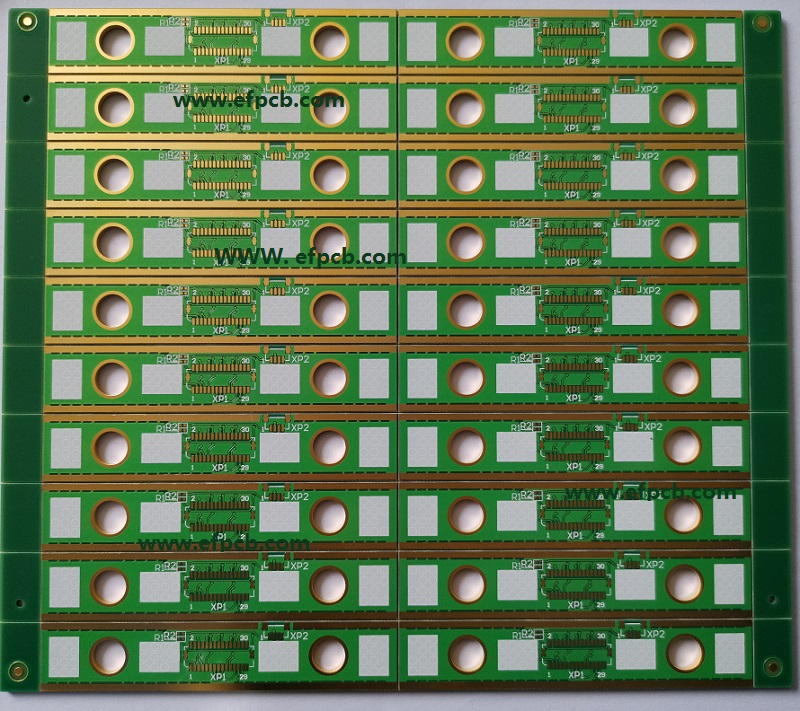

In the present electronic Industry, PCB gold plating of Hard Gold PCB is a common practice. The use of this PCB is mentioned by an applications on account of the environment type it will be used in. In the PCB business, the usage of gold in plating PCBs is ordinary. The interest for Gold plated PCBs has been growing after some time. Regarding plated circuit sheets, you will get to know everything here.

PCB Gold Plating

The most widely recognized approach to putting away gold onto the external layer of a circuit board through plating is fundamentally PCB gold plating. Different materials like gold, nickel, copper, and tin are accessible. Nevertheless, a gold-plated circuit board is fascinating. For plating circuit sheets, Gold is useful due to its conductive properties.

Gold has various properties isolated from its conductive nature. For PCB plating, these make it ideal. On PCBs with layer switches, gold contact surfaces are used by subject matter experts. You can interface gold particles to the PCBs as the gold plating solid areas for has. Using electrochemical plating, Gold plating is a surface finishing strategy to store gold onto another metal.

Gold Plating Pattern of PCB

Two classes of plating processes are accessible in the PCB business; electrolytic plating and Electroless plating.

Electroless plating

On a substrate's surface, this is a cycle by which a metal particle is kept to make a metal plating layer. Outwardly wellspring of power, Electroless plating doesn't depend upon the liquid plan. An external current isn't needed in this Plating Gold PCB process. In the Electroless plating layer, there is a uniform thickness.

Electroplating

Putting away a thick metal or mix on the PCB's surface is locked in with this connection. To cover the metal, this cooperation uses an external current. The anode goes through an oxidation reaction, electrons are delivered, and a short time later the metal particles become cations during this connection.

Kinds of Gold Surface Consummations in PCB

Gold Fingers

In various applications, Gold fingers are useful. For the relationship of the edge card, a couple of gold contacts are perfect. A gold-plated connector of a PCB is a gold finger. A gold-plated terminal is incorporated by Gold fingers. The smooth power and data move are worked with by this surface finish in a PCB. Especially, Gold fingers are used for edge contacts. They can gainfully go against wearing and tearing.

Electroless Nickel/Immersion Gold (ENIG)

To the copper surface, this surface finishing interfaces nickel and gold. For this cycle, complex power supply contraptions are not used by it. Pickling, activation, small scale drawing, cleaning, and nickel and Electroless plating are related with the ENIG cycle oftentimes. The plating of auto-synergist nickel on the copper pad is the critical stage here. Limits like added substance pH, temperature, and obsession do these.

Electroplated Nickel Gold (ENG)

Since the improvement of PCB, Electroplated Gold or Nickel has been existing. The surface aide of the circuit board is covered by this kind of surface culmination covers with a layer of nickel. To cover the surface, a layer of gold is used by it. Gold is placed in the substance syrup after the nickel liquid has been disposed of freely. In the electroplating chamber, the pre-dealt with PCB is then lowered by the maker.

In the electronic business, This PCB gold plating is renowned. This is in light of the fact that gold is wearing and oxidation-protected as a material.

Factors Thought While Plating Gold

Porosity

The course of gold plating is porous. With the thickness of the covering, this has a tremendous relationship. Right when above 0.76 μm, the porosity is low. Right when it is underneath 0.38 μm, the Porosity rises rapidly. A critical component to consider is Porosity.

Wear

The future of the plated not permanently set up by two critical characteristics of the surface treatment. These two ascribes are contact and Hardness coefficient. As the contact coefficient lessens, the surface treatment life increases. The wearing check of gold is redesigned by Electroplated gold.

Hard Gold PCB

A layer of gold with additional hardeners is accessible in hard gold PCB to help with further developing strength. For plating a circuit board, hard gold is a durable material ideal. Gold is used for high-wear areas like edge connectors during circuit board fabricate. Metal contacts created utilizing gold are featured by most circuit sheets.

An outline of a surface fruition for PCBs is Hard gold. In applications where crushing is required, hard gold PCBs are perfect for use.

Gold Plated Circuit Board Properties

In the equipment business, the gold-plated circuit board is typically used. It is made a significant resource for people by the sharp appearance of gold. In any case, in the devices business, its properties make it a significantly esteemed material. Extraordinary mechanical, electrical, and warm properties are featured by Gold features. For use in electronic parts, these seek after them an optimal choice. A lot of properties are featured by a gold plated circuit board which integrate;

Heat Confirmation

For applications including high temperatures, a gold-plated circuit board is perfect. Various materials are protected by this circuit board safeguards from overheating. A conditioning spot of 1062 ℃ is incorporated by Gold. This suggests that the ability to coordinate power is accessible in gold. Under exceptional temperatures, Gold plated circuit sheets will perform well. For applications that may be introduced to high temperatures, this makes it ideal.

Wear Resistance

Gold plated circuit sheets are trustworthy. Wearing and tearing can be gone against by this PCB. For the electronic parts, the covering on this circuit board fills in as a protect. To stressing degradation, Gold plated sheets aren't frail. It won't hurt due to stressing as gold doesn't disintegrate. The gold plating done on this board is incredibly solid.

Reflectivity

It is sought after an optimal choice in parts by the keen thought of gold. More critical proportions of UV radiation are featured by Gold plated circuit sheets. Infrared radiation is reflected by them which keep devices in cool conditions. For transport and satellite arrangement, gold plated circuit sheets are focus materials Along these lines.

Disintegration Block

In gold plated circuit sheets, this is one of the remarkable properties. Gold is impenetrable to disintegration. This suggests that any disintegration can be borne by it. To any rust or compound, it won't answer. It won't hurt but gold can stain. For electronic parts, Gold's security from utilization is critical. This is in light of the fact that a less utilitarian electrical affiliation could happen due to oxidation.

Expanded area of Affiliation

A gold-plated circuit board is extraordinarily adaptable and flexible. Into thin wire, Gold as a material can relax under pressure. Consequently, more surface area is covered by it. Electronic contraptions can hold working incredible as a result of the Hard Gold PCB board's versatility.