Go Deep Into the Facts about Printed Circuit Boards

Keywords: Printed Circuit Board Manufacturer, Printed Circuit Board

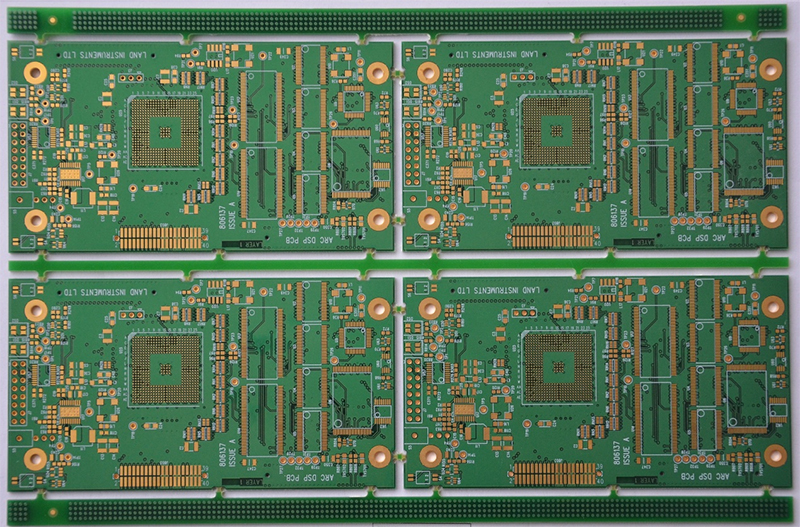

Printed circuit boards, or PCBs, are familiar to anybody who has ever opened up an electronic device. They are the brains and heart of most electronic devices and are thin, flat, frequently green rectangular substrates covered in a labyrinth of tiny copper lines and silver pads. Learning about circuit boards and the many types of circuit boards that are available, the components that are utilized on these circuit boards, and the Printed Circuit Board Manufacturing procedures is necessary to comprehend them. Understanding the development of printed circuit boards is a good place to start.

In the 1950s, printed circuit boards took the place of point-to-point assembly in the majority of electronics. Wires soldered to terminal strips and boards stamped with metal loops were utilized in the point-to-point assembly. Small electronic components and their wires, as well as the wires from bigger devices like transformers, were directly soldered to the terminals of a point-to-point driven device.

Enter the PCB, which eliminated practically all of the wiring needed in wire wrapping and point-to-point assembly and allowed mass manufacture. A major portion of the PCB manufacturing process may be automated, reducing the possibility of design errors that could result in subpar prototypes or defective boards. Before the board is even created, a PCB maker may input the specs into software that performs thorough design tests to guarantee the board will function at its peak. Additionally, automated production is less expensive than alternative construction techniques.

The diverse printed circuit board (PCB) manufacturing processes used by Printed Circuit Board Manufacturer, components utilized on the boards, and fabrication issues are all covered in this article.

Variety of Printed Circuit Board

Today's circuit boards come in a variety of forms. The way printed circuit boards are made, including single-sided, double-sided, and multilayer board designs, may be used to classify them.

Undoubled PCBs

There is only one substrate layer on single-sided PCBs. On one side of the substrate, a thin coating of metal is applied. Because of its great electrical conductivity, copper is frequently utilized. This layer establishes a conductive path for electrical signals and power between different electronic parts. The following layer is a protective solder mask, and the last layer may be a silkscreen coating to label the board's components. Simple electronics employ single-sided PCBs, which are more easily mass-produced and less expensive than other PCB kinds.

Two-Sided PCBs

Because the two sides allow for the incorporation of more complicated circuitry, double-sided PCBs are far more often utilized than single-sided boards. They feature a single layer of substrate, just like single-sided PCBs, but the circuit components and conductive metal are attached to both sides. The components are subsequently connected using either surface mounting or through-hole installation.

Through-hole technology, which is frequently spelled "thru-hole," connects components by using tiny wires called leads that pass through the board's holes. The identical component or circuit is connected to the leads at either end by soldering. Either manual labor or mechanized insertion mount equipment is used for this. Circuits that must bear more strain are still mounted through-hole because the connection is more secure thanks to soldering and leads that pass through the board. Products for the military and aerospace industry frequently employ through-hole PCBs.

The board does not need to have holes drilled for surface installation. The PCB is immediately attached to the components. Smaller leads or no leads at all are used in this technique. Because handling and processing costs for surface mount PCBs are far lower than for through-hole PCBs, they have gained in popularity. Either manually or in bulk, components can be soldered onto the board.

Layered PCBs

Insulating materials are used to separate the substrate layers on multilayer PCBs. The components on multi-layer boards are linked by either through-hole or surface mounting, using the same technology as double-sided PCBs. Typically, multilayer boards contain between four and ten layers, although they might have more if the product requires it. They are frequently used in specialized applications like PCBs for medical devices as well as for computers and servers.

Soldering Procedures

Hand soldering is one method of joining components to circuit boards mechanically and providing an electrically conductive path between the pins or leads of the component and the circuit pads or traces on the board. This method of joining uses an iron, solder, soldering wick, and flux to heat a low-melting temperature alloy, typically a tin or lead alloy. Bulk soldering is a technique called wave soldering. To avoid thermal shock, a coating of flux is added to the board's bottom, which is then gradually warmed. After that, a pan of molten solder is passed over the PCBs. To fuse all of the components to the board, a pump in the pan washes solder over it. Similar to wave soldering, selective soldering only uses flux on certain parts that need to be soldered.

Devices for Interconnecting Printed Circuit Board Components

Printed circuit boards are frequently linked together using interconnect devices, which are also occasionally used to link the board to an electrical device. An integrated circuit chip, which is a collection of electrical circuits on a single tiny flat piece (or chip); can also be connected to a printed circuit board using these connectors.

Edge Connectors are utilized on a PCB's edge and plug into a device's corresponding socket. To transmit electrical impulses from circuit traces on the PCB to the connection socket, edge connectors feature metallic tracks, or traces, on their sides. The I/O requirements of the circuit dictate how many pins are within the plastic box that is open on one side of the sockets. To ensure correct polarity and ensure that only the right matching connection may be inserted, connectors are often keyed and may also include tabs or notches.

D-Connectors, also known as D-subminiature, acquire their name from the metal shields that approximately resemble a D. They are made up of two or more parallel rows of sockets or pins encased in a D-shaped metal shield that protects against electromagnetic interference and supports the connector. The pins are not attached to a wire when used with a PCB; rather, they are soldered directly to the printed circuit board. To allow a cable to be connected to the edge of the PCB assembly, D-connectors are frequently positioned at a right angle to the PCB.

o create ribbon cable connectors, several smaller cables are laid parallel to one another. It is simple to attach an insulation displacement connection, commonly known as an IDC, to one end thanks to the several cables and row of acute forked contacts. The ribbon cable connection is typically ended at both ends, however, occasionally just one end is IDC terminated.

When an integrated circuit chip has to be a detachable component of a Printed Circuit Board, IC Sockets are employed. Normally, these chips are soldered to the board, but an IC socket is used in applications like prototypes where the chips must be quickly removed and reprogrammed without requiring unsoldering and resoldering connections.