Getting Into the World of PCB Manufacturing

Keywords: PCB Manufacturer

Printed Circuit Boards (PCBs) are the unsung heroes of our technological world. They serve as the backbone for nearly every electronic device we use, from smartphones and laptops to medical equipment and automotive systems. Behind these intricate and essential components lies the PCB manufacturer, a crucial player in the electronics industry. In this comprehensive guide, we'll delve into the world of PCB manufacturing to help you understand the process, key considerations, and the importance of choosing the right PCB manufacturer for your specific needs.

What is PCB Manufacturing?

Before we dive into the world of PCB manufacturers, it's essential to understand the basics. PCB manufacturing is the process of designing and producing printed circuit boards, which are the fundamental building blocks of electronic devices. These boards contain conductive pathways and components that enable the flow of electricity and data.

PCBs come in various types, such as single-sided, double-sided, and multi-layer boards.

The manufacturing process involves designing the PCB layout, fabricating the board, and assembling components.

The PCB Manufacturing Process

PCB manufacturing is a multi-step process that requires precision and expertise. Here's a rundown of the procedures:

Design: PCB designers create a layout that includes the placement of components, conductive traces, and the board's dimensions.

Material Selection: The choice of materials, like FR-4, impacts the PCB's properties, such as heat resistance and durability.

Imaging: The design is transferred onto a copper-clad laminate through a process called imaging.

Etching: Unwanted copper is removed using a chemical etching process, leaving behind the desired traces.

Drilling: Holes for components and vias are drilled into the board.

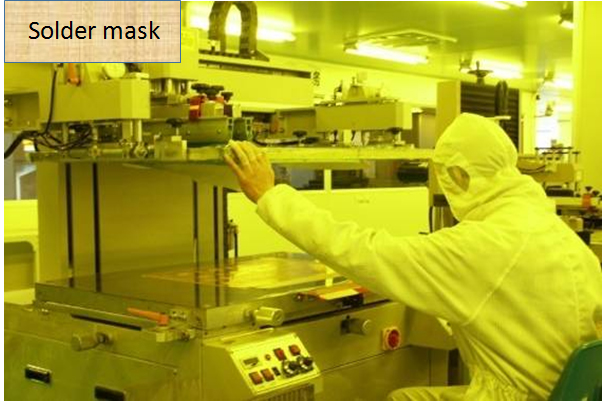

Plating and Masking: Conductive pathways are plated with copper, and the board is coated with a solder mask to protect it.

Component Assembly: Electronic components are soldered onto the board.

Testing: PCBs undergo rigorous testing to ensure they meet quality standards.

Types of PCB Manufacturers

When it comes to choosing a PCB manufacturer, you'll have several options:

Local Manufacturers: These are PCB manufacturers in your region, offering proximity and potentially shorter lead times.

Offshore Manufacturers: Overseas manufacturers often provide cost-effective solutions, but shipping times and communication may be challenges.

Prototype Manufacturers: These specialized manufacturers are ideal for small-scale production runs and prototypes.

Full-Service Manufacturers: They offer end-to-end solutions, from design to assembly, making them suitable for large-scale projects.

Considerations When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is crucial for the success of your project. Here are some important considerations to think about:

Experience: Look for manufacturers with a proven track record in your industry.

Quality Control: Confirm that the manufacturer has strong quality control procedures in place.

Cost: Compare quotes and consider the balance between cost and quality.

Lead Times: Evaluate the manufacturer's ability to meet your project timeline.

Communication: Effective communication is key, especially if you choose an offshore manufacturer.

The Importance of Quality Assurance

Quality assurance is paramount in PCB manufacturing. A reliable manufacturer will have strict quality control measures in place to identify and rectify any defects. Ensuring high-quality PCBs is essential to prevent electronic malfunctions and maintain the integrity of your products.

Emerging Trends in PCB Manufacturing

As technology continues to evolve, so does the field of PCB manufacturing. Staying abreast of the latest trends and advancements is essential for anyone involved in the electronics industry.

Here are some notable trends to watch for in PCB manufacturing:

Miniaturization: With the demand for smaller and more compact electronic devices, PCB manufacturers are increasingly working on producing miniaturized components with greater functionality. This trend involves advanced manufacturing techniques like HDI (High-Density Interconnect) and microvia technology.

Flexible PCBs: Flexible printed circuit boards are becoming more prevalent in applications where rigid boards are not suitable. FPCBs offer greater design flexibility and can be bent or folded, making them ideal for wearables and portable devices.

Sustainable Practices: PCB manufacturing is becoming more eco-friendly. A PCB manufacturer is adopting practices such as waste reduction, lead-free soldering, and using environmentally friendly materials to reduce their ecological footprint.

IoT Integration: As the Internet of Things (IoT) continues to grow, PCB manufacturers are adapting by producing boards optimized for IoT devices. These PCBs are designed to be energy-efficient and capable of handling a myriad of sensors and communication modules.

3D Printing: 3D printing technology is finding its way into PCB manufacturing, allowing for more complex and customized board designs.

Future Innovations in PCB Manufacturing

Even more intriguing possibilities await in the future of PCB fabrication. Researchers and producers are investigating a variety of technologies, including:

Quantum Computing Integration: As quantum computing technology matures, PCB manufacturers will need to develop boards that can support the unique requirements of quantum processors.

Nanotechnology: Incorporating nanoscale components and materials into PCBs could lead to enhanced performance and entirely new applications.

AI-Optimized Manufacturing: Artificial intelligence and machine learning will play a significant role in optimizing the manufacturing process, from design to assembly, leading to greater efficiency and cost savings.

Biodegradable PCBs: Researchers are working on developing biodegradable PCBs to address the growing problem of electronic waste. These boards could significantly reduce environmental impact.

Wireless Power Transfer: PCBs capable of wirelessly transferring power to devices without the need for physical connectors are an exciting prospect for the future.

Tips for Successful Collaboration with PCB Manufacturers

Once you've selected a PCB manufacturer and initiated your project, it's essential to establish a successful collaboration. Effective communication and partnership can make a significant difference in the outcome of your PCB manufacturing project. Here are some tips for a productive collaboration:

Clear Communication: Maintain open and transparent communication with your chosen manufacturer. Ensure that all specifications, expectations, and project timelines are communicated.

Regular Updates: Stay up to date on the status of your project. Regular manufacturer updates might assist you in identifying and addressing any difficulties early in the process.

Design Review: Collaborate with the manufacturer during the design review phase. Their expertise can help optimize the PCB design for manufacturability, potentially saving time and costs.

Quality Control: Discuss quality control measures and agree on the level of testing and quality assurance that will be applied to your project.

Flexibility: Be prepared to adapt to unforeseen challenges or changes in project requirements. A flexible and collaborative approach can help overcome obstacles more effectively.

Conclusion

PCB manufacturing is a vital part of the electronics industry, and choosing the right manufacturer is a decision that can significantly impact the success of your projects. Understanding the PCB manufacturing process, types of PCB manufacturer, and key considerations will empower you to make informed choices. Whether you're a seasoned engineer or a newcomer to the world of electronics, this guide serves as a valuable resource for navigating the intricate realm of PCB manufacturing.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact