Get Into the World of PCB Prototypes

Keywords: PCB Prototype China

At the heart of every successful PCB Prototype China lies a meticulously crafted design. This phase involves creating a schematic diagram that outlines the components, connections, and functionalities of the circuit. Using specialized software, such as Altium Designer or Eagle, designers arrange components and trace connections to ensure proper signal flow and electrical integrity.

Materials and Manufacturing Considerations

Selecting the right materials is crucial for achieving the desired performance and durability in the final product. PCBs can be made from various materials, such as FR-4, flexible materials like polyimide, and even specialized materials for high-frequency applications. The choice of material depends on factors like circuit complexity, operating environment, and cost constraints.

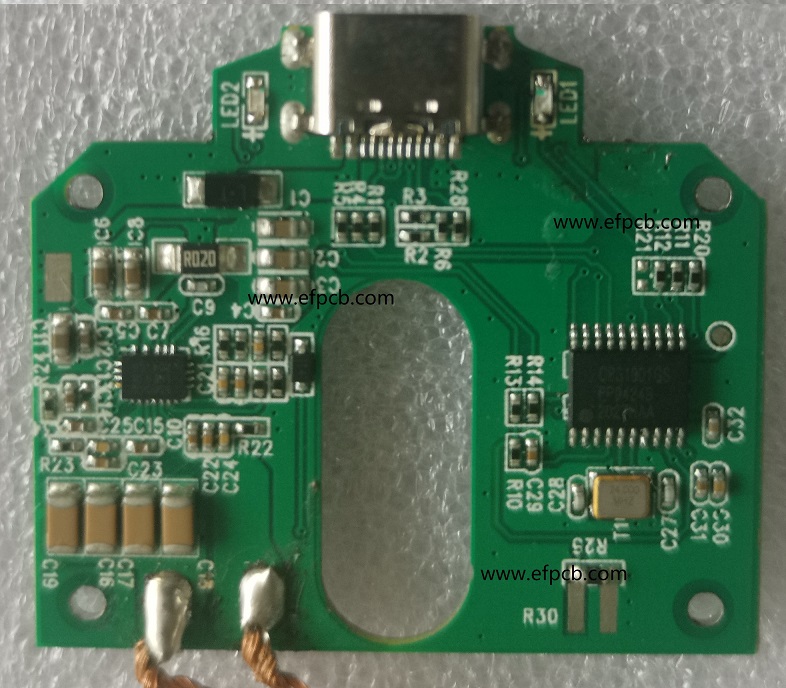

Manufacturing methods also play a pivotal role. Two main techniques—through-hole and surface-mount technology (SMT)—are used to mount components on the PCB. SMT has gained popularity due to its compactness, reduced weight, and ability to accommodate miniaturized components.

PCB Prototyping Techniques

Once the design is ready, it's time to bring it to life through prototyping. There are several prototyping techniques available for PCB Prototype China, each with its benefits:

- Breadboarding: A simple method involving manually connecting components on a breadboard for rapid testing and iteration. While great for early-stage experimentation, it's limited in terms of complexity and performance.

- Stripboard/Veroboard: This involves soldering components onto a pre-perforated board, providing more stability than a breadboard. However, it's still best suited for basic prototypes.

- PCB Prototyping Services: Professional PCB prototype manufacturers offer a more comprehensive solution. They take your design files and produce a prototype that closely resembles the final product, often using rapid manufacturing techniques like CNC milling or additive printing for rapid iterations.

- Iteration and Testing: Prototyping is not a one-shot process; it involves iteration and refinement. Once the initial prototype is assembled, rigorous testing ensues. Various tests, including functional, electrical, and thermal tests, are conducted to identify potential issues and ensure the prototype meets the intended specifications.

- Troubleshooting and Optimization: Testing n PCB Prototype China often reveals areas for improvement. Whether it's a design flaw, an electrical inconsistency, or a mechanical issue, this stage is crucial for optimization. Changes are made to the design, and the process returns to prototyping and testing.