Get into the Details of Gold Plating for PCBs

Keywords: Gold Finger PCB, Plating Gold PCB

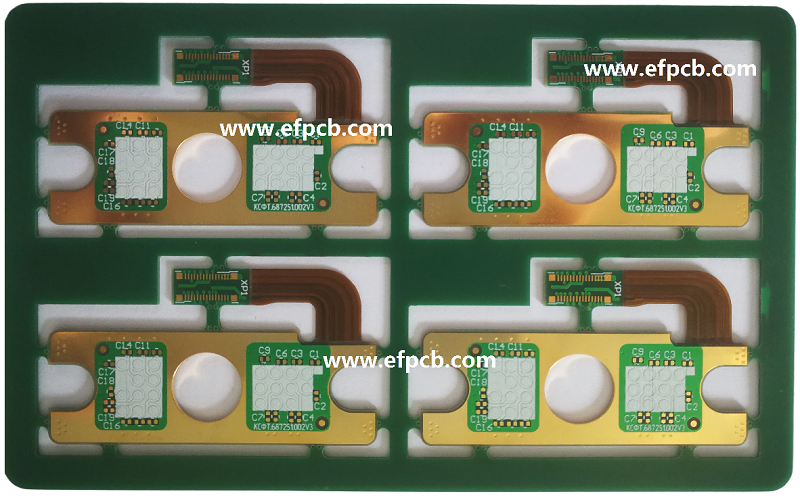

Plating Gold PCB is frequently used to improve electrical conductivity while making printed circuit boards (PCBs). There is still a big market for gold plating. Why is gold used on a circuit board, and what is PCB gold plating ?

How does gold plating work?

During the gold plating process, gold plates are added to PCBs to improve the conductivity of other metals. Gold plating is the most common and user-friendly technique of adding gold to a PCB, and it's also a rather straightforward procedure.

It functions by generating a gold-plating solution with a very high concentration of gold ions. Gold atoms with at least one missing electron are known as gold ions. When the gold solution is given to a surface with positively charged atoms or the cathode, the negatively charged atoms join chemically with the positively charged atoms.

Less than 15 millionths of an inch of gold are produced on the surface that is being gold-plated thanks to this technique.

Why Are PCBs Gold-Plated?

The primary justification for using gold plating on Gold Finger PCB is that it is more durable than immersion gold. Particularly beneficial for sections that often come into touch with other electrical parts is hard gold. For instance, the gold fingers that link a printed circuit board to another circuit board are more frequently coated with gold.

Certain gold fingers must be able to endure the wear that results from repetitive or faulty insertion since they are inserted and withdrawn from another circuit board several times throughout a PCB lifespan. Gold-plated gold fingers are less likely to sustain damage during this procedure than gold fingers manufactured from pure gold.

The ease of gold plating makes it possible that it is preferred. If a person lacks the necessary tools to employ gold immersion for their circuit board, they may still use gold plating. Also, if one only has to plate a tiny part of a PCB, they may elect to brush just that region with the gold plating solution rather than submerging the entire Board.

The fact that gold plating costs more because the coating of gold is thicker is one disadvantage. Of course, you won't be able to solder the Plating Gold PCB if it's too thick. Yet, for many producers, the appropriateness of hard gold for slide and touch contacts may make the cost worthwhile.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact