Get Into the Deep Insights of Semiconductor Test Board

Keywords: semiconductor test board

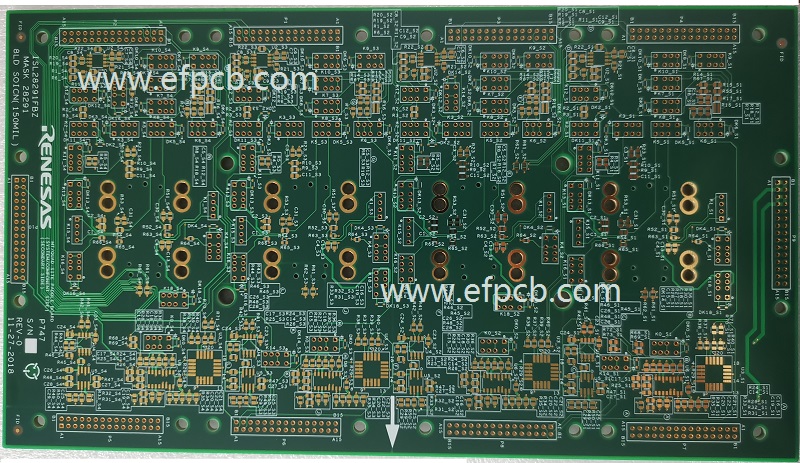

Semiconductor test boards, often called probe cards or test fixtures, are critical equipment in the semiconductor industry for testing and verifying integrated circuits (ICs) and other semiconductor devices. These boards allow you to electrically connect the devices under test (DUTs) to test equipment such as automated test equipment (ATE) and semiconductor test systems. The test boards operate as a link between the DUT and the testing equipment, allowing for accurate measurement and characterization of the device's electrical performance.

What is the difference between a semiconductor test board and a standard PCB?

A semiconductor test board is specially intended to test and characterize semiconductor devices such as integrated circuits (ICs) and chips. A PCB is used to assemble and combine electronic components in a working system.

Complexity

Semiconductor test boards are frequently more sophisticated, with dense layouts and high-frequency signals designed to swiftly interact with current integrated circuits. PCBs can be basic or complicated, depending on the application.

Components

Semiconductor test boards feature connectors, interfaces, and specialized components for stimulating and observing the devices being tested. PCBs include general-purpose components that enable system functionality.

Design

The structure and interconnections of a semiconductor test board are designed to provide access and control signals for testing semiconductor devices. PCB design optimizes routing for the desired system architecture and performance.

Access

Semiconductor test boards allow direct access to an IC's internal signals using probes, vias, and other access points. PCBs often regard integrated circuits as black-box components.

Advantages of Semiconductor Test Boards

Direct access to pins and signals

Semiconductor test boards have sockets and interconnects that allow direct physical access to all of the input/output pins and internal signals of the semiconductor device being tested. This allows for complete electrical testing.

Controllability of test conditions

Semiconductor test boards provide precise control over voltage supplies, clock signals, input stimuli, temperature, and other parameters applied to the device being tested. This contributes to a better understanding of device behavior in unusual situations.

Custom test features

Semiconductor test boards might include specialized circuits like signal generators, logic analyzers, and bus analyzers that are tuned to the individual test needs.

Rapid Prototyping

Engineers may quickly test new device samples, configurations, and interfaces on bespoke Semiconductor test boards without the need to construct whole systems.

Debugging capabilities

Engineers can use features like probes, vias, and debug modes to help them identify and rectify faults in silicon or software.

Automated or repeatable testing

Semiconductor testing may be automated using scripts and patterns created to evaluate functionality and standards. This facilitates regression testing.

Electrical isolation

Semiconductor test boards isolate the device being tested from the test equipment, preventing damage to expensive equipment.

Application and categorization of semiconductor test boards

The semiconductor test board is available in a variety of configurations to meet specific testing needs based on the application environment and chip characteristics. Understanding the different types of test boards is vital for improving the testing process and assuring the quality and performance of semiconductor devices in various sectors.

Digital Signal Test Boards

Digital signal test boards are specially developed for assessing digital integrated circuits (ICs) or chips. These test boards enable the precise and efficient testing of digital devices such as microprocessors, microcontrollers, and memory chips.

High-Speed I/O Test Boards

As data rates in digital systems increase, high-speed IO test boards are critical for evaluating SERDES (serializer/deserializer) and transceiver chips. These boards rigorously evaluate characteristics such as data rate, jitter, bit error rate, and channel modeling to provide the most dependable high-speed data transfer across interfaces such as PCIe, USB, and Ethernet.

Mixed Signal Test Boards

Modern semiconductor devices include both digital and analog components onto a single chip, necessitating the use of mixed-signal test boards to verify integrated functioning. These boards enable simultaneous testing of digital and analog features, guaranteeing smooth interaction across sections and full chip validation. Important for applications such as data converters and communication interfaces.

Radio Frequency (RF) Test Boards

RF test boards are designed for semiconductors that operate in the radio frequency spectrum, which are popular in wireless communication systems like Wi-Fi, Bluetooth, and cellular networks. These boards test and evaluate devices' RF performance, including frequency, modulation, power, and noise figures. RF test boards serve an important role in improving the performance of wireless communication components.

Power Management Test Boards

Power management test boards evaluate the efficiency and reliability of power management integrated circuits (PMICs). These ICs control the power supply, distribution, and consumption of electronic equipment. The test boards validate essential factors like as voltage control, current handling capabilities, and power conversion efficiency, guaranteeing that the PMIC can fulfill power needs in a variety of applications.

Analog Signal Test boards

Analog signal test boards are used to evaluate the performance of analog integrated circuits and components that operate with continuous signals rather than discrete ones. These boards make it easier to examine a variety of analog parameters such as voltage, current, and frequency, as well as signal-to-noise ratio and distortion. Analog signal test boards are essential for verifying amplifier, filter, and sensor circuits.

Manufacturing aspects of semiconductor test boards

The manufacturing of semiconductor test boards includes several essential factors that have a direct influence on the test boards' performance and usefulness. These elements are critical to assuring the accuracy, reliability, and efficiency of semiconductor device testing. Some of the important manufacturing issues are:

PCB substrates

Test boards are made of high-frequency laminates such as FR4, polyimide, Teflon, and so on. The choice of substrate is determined by the necessary electrical performance. Rigid, flexible, and rigid-flex boards are all choices.

Layer Count

Test boards are made of high-frequency laminates such as FR4, polyimide, Teflon, and so on. The choice of substrate is determined by the necessary electrical performance. Rigid, flexible, and rigid-flex boards are all choices.

Board Finishes

Immersion gold, ENIG, and HASL are popular finishes. A critical element is assuring compatibility with test socket connections. In some circumstances, selective gold plating is necessary to satisfy specifications.

Trace routing

Matched length routing, serpentine traces, and specialized isolative guard traces are all excellent ways to regulate impedance, reduce crosstalk, and improve signal integrity.

Test Sockets

Zero insertion force (ZIF) sockets, pogo pin sockets, and probes are soldered to the board to interface with the device being tested.

Interconnects

Vias, probes, and test points allow access to internal device signals. Microvias provide high-density access. Buried probes are an alternative.

Passive integration

Test equipment like current sensors may be incorporated on the board itself. Passives assist regulate impedance.

Advanced Materials

Metal core boards, ceramic substrates, and liquid crystal polymers can improve heat and high-frequency performance.

Advanced Processes

Laser drilling produces high-density, tiny vias. Microvias assist in incorporating passives. Direct imaging promotes tolerance.

Functional Testing

Bed-of-nails in-circuit testers verify completed board construction. Flying probe testing is also prevalent.

Quality and Reliability

Testing procedures such as X-ray, micro sectioning, and environmental stress screening guarantee that boards are strong.

Manufacturing expertise

Use EFPCB's experience in sophisticated PCB technology to assure high-quality, dependable semiconductor test boards.

Proper Use and Maintenance of Semiconductor Test Boards

To ensure the long-term stability and performance of semiconductor test boards, it is vital to use and maintain them properly.

Maintenance

Periodically clean the semiconductor test board using compressed air or isopropyl alcohol to remove any dust, dirt, or residues that may have accumulated.

Check for overheating and ensure appropriate ventilation. Heat sinks may require occasional cleaning.

Check for evidence of oxidation or material degradation, particularly on connections and exposed metallic surfaces.