Get Acquainted with Tips for PCB Design

Keywords: PCB Fabrication

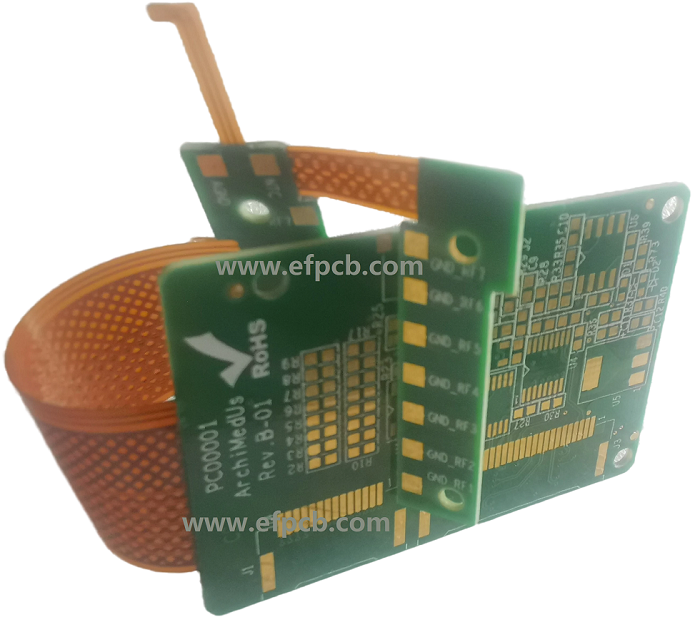

Applications for high-power electronic items are numerous and include consumer goods, medical technology, and automobiles. PCB Fabrication is one of the primary uses for high-power electronics. A manufacturing facility with several motors and other large gear has enormous power needs. It is predicted that the printed circuit boards (PCB) used in such high-power electronics would solve issues with excessive heat generation and human safety.

High-current and high-voltage circuit design present several complicated problems. If a high-speed or mixed-signal circuit is included in the design, the difficulties become more serious.

Such circumstances make handling PCB manufacture a little challenging. As a result, designing an effective, high-power PCB necessitates choosing the right substrate material, placing components correctly, designing the board layout and stack-up strategically, and adhering to established regulatory criteria.

Design Standards for PCBs

The high-power electronic parts and the high-current-carrying traces typically produce too much heat. To swiftly transmit the excess heat, the PCB material should have a high thermal conductivity. The rate at which heat is transmitted from a thermal source to cooler PCB sections is known as thermal conductivity or K.

PCB Substrate Choice

A multi-layer PCB's layers should all have substrates and laminates that have the same coefficient of thermal expansion, or CTE. Extreme heat can cause a board's temperature to vary, but laminates with identical CTE will expand or contract evenly, preventing the board from deforming mechanically.

The PCB substrate should have a glass transition, Tg value greater than the maximum working temperature of the electronic device, for high-power applications. A minimum of 20 °C margin is advised.

Component Positioning

Due to their high heat output, high-power components like voltage converters and power amplifiers should be given priority. To reduce their trace lengths, it is also advised to group the components they are related to. Digital integrated circuits (ICs) with many pins, such as FPGAs and CPUs, generate heat and should be positioned in the middle of the board for even thermal dispersion. Sensitive circuits should be located far from components that produce heat.

Conclusion

User safety and overheating are worries when PCB Fabrication for high-power devices. Use the aforementioned advice to construct a secure PCB for a high-power electrical gadget. You may incorporate an integrated temperature sensor that alerts the user to improve product safety.