Get Acquainted With the Difference between PCB and PCBA

Keywords: PCB Assembly China, Printed Circuits Assembly

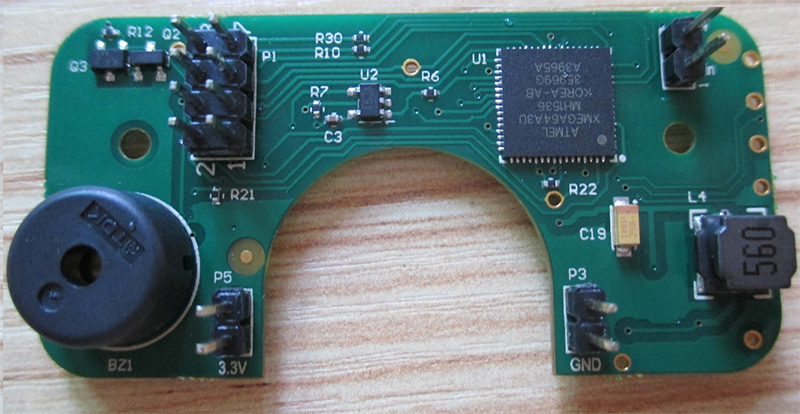

After all the components have been soldered and mounted on a printed circuit board, the final board is known as a printed circuit board assembly (PCBA). The PCB Assembly China is created by using the conductive paths carved in the laminated copper sheets of PCBs inside a non-conductive substrate. The final step in creating an electronic gadget that is completely functional is attaching the electronic components to the PCBs.

In the electronics sector, the phrases printed circuit board (PCB) and printed circuit board assembly (PCBA) are both crucial. Although they are two separate concepts, some people mistakenly use them interchangeably.

The primary distinction between these two names is that PCB refers to a board with no circuitry on it, and PCBA refers to a board with all the electrical components it needs to function. A PCBA is a finished and working board whereas a PCB is not yet functional because it lacks the necessary components. A PCBA is constructed on top of an existing PCB; PCBs and PCBAs are two distinct components of the same process.

In this article, we'll look more closely at the definitions of PCB and PCBA as well as the distinctions between the two terminologies.

A PCB

The basis of contemporary electrical gadgets is PCB technology. Electronic components are mechanically and electrically connected by them. The actual boards are constructed from laminated materials like fiberglass or composite epoxy, and they include electrical channels connecting their various components. According to the established PCB design, these paths are either printed or engraved into the board.

Variety of PCBs

The primary PCB kinds are:

- The most basic sort of PCBs is single-layer PCBs, which are covered with a layer of solder mask and a single layer of conducting material. The components of the PCB are silkscreened with markings.

- Double-layer PCBs are more flexible and smaller than single-layer PCBs because they feature a layer of conducting material on the top and bottom of the board.

- Multi-layer PCBs are utilized in more complicated applications and feature more than two conducting layers.

- Rigid, flexible, and flex-rigid PCBs are further popular PCB kinds.

Used materials

Typically, fiberglass, composite epoxy, or another laminate material serves as the substrate for PCBs. Most frequently, copper is used as the conducting material on one or both sides of the board. Copper is also used to make printed circuits, which are plated or etched into the substrate by the design. Tin-lead is used as a coating on the circuits to stop oxidation. To boost conductivity, PCBs include contact fingers on their exterior borders that are additionally covered with tin-lead and other compounds, like nickel and gold.

Applications

A vast variety of electronic products, including consumer electronics, industrial machinery, robots, auto parts, and medical equipment employ Printed Circuits Assembly. Several examples are:

- Mobile phones

- Computers

- Radios

- TVs

- System of satellites

- Calculators

- Printers

- Lighting devices

- Appliances

- Pacemakers

- Health imaging equipment

- Commercial controls

- Engine control systems

- Data storage apparatus

- Telephone poles

What Exactly Is PCBA Definition?

A PCBA is a finished PCB assembly that includes all of the electronic components required to make the board work as intended whereas a PCB refers to a blank board. PCBA can also refer to the procedure of putting the board together with the required parts. For PCB assembly, a PCBA business may employ one of two major techniques:

Surface-Mounting Technology

The assembly method known as surface-mount technology (SMT) involves attaching electrical components to a PCB's surface. Its high degrees of automation and flexibility enable higher connection densities. It allows manufacturers to incorporate intricate circuitry onto tiny components.

The four fundamental PCBA SMT stages are:

The PCB is first prepared by the assembler, who applies solder paste where it is required on the board.

The next step is for the assembler to install the components on the board, usually with the aid of a pick-and-place machine.

Reflow soldering: The boards are heated in a reflow oven by the assembler until the solder paste reaches the temperature necessary for the formation of solder junctions.

Inspection: The assembler performs inspections at every stage of the SMT procedure, including before and after reflow soldering and before and after joining the components.

Through-Hole Technology

Through-hole technology is an assembly method that entails creating holes on a PCB so that leads, which are used to attach electrical components, can pass through. Though it is an older technique than SMT, it strengthens the bond between the board and the components, leading to more dependable and long-lasting assemblies.

Thru-hole assembly can be done manually or somewhat automatically. The following are the steps in the PCBA thru-hole process:

Drilling the holes: Drilling the holes into the board is the first stage in the thru-hole procedure. The component leads must fit snugly in these openings. After that, the assembler inserts the leads into the holes. The procedure continues with the stage of soldering. This process makes sure the parts are securely fastened.

Inspection: The assembly is examined repeatedly to make sure the PCBA will perform as intended.

What Relationship Has PCBA and PCB to One Another?

The end products of the same general process are PCB and PCBA, which are two distinct processes. A PCB is a blank circuit board with no electrical components attached whereas a PCBA is a full assembly with all the components required for the board to function as needed for the desired application. If a PCB is not yet operational, a PCBA is readied for use in an electrical device.

Due to the numerous components and steps needed in PCB assembly, generating a finished PCBA is more difficult than producing a blank board. A PCBA is also more expensive to construct than a blank PCB. However, to construct a finished board, both procedures are required. Without a PCB, you cannot make a PCBA. The initial phase in the process is PCB manufacturing, and PCBA manufacturing builds on that first step.

The packaging of PCBs and PCBAs is another distinction. PCB Assembly China needs compartmental or anti-static packaging whereas PCBs are commonly wrapped using vacuum packing.