Get a Smoother PCB Assembly China

Keywords: PCB Assembly, PCB Assembly China

All electrical contraptions depend on printed circuit sheets or PCBs. Regardless, a couple of recommended methods ought to be gone on in their improvement for the PCB to work continually. To ensure that your resulting PCB Social affair system goes even more effectively, follow these six phases:

Convincing correspondence

To keep away from having your PCB created disregarding your solicitations, you should at first expose out channels of correspondence with your PCB gathering assistant. You ought to avow that the PCB accessory is familiar with your specific necessities. Experienced accessories could give you significant insight about better techniques, material decision, most recent things, or any mix of the recently referenced. They are also instructed about industry best practices. In this manner, you will not need to make the wheel without any planning.

DFM check

Running an arrangement for collecting (DFM) test is a critical stage in guaranteeing your PCBs are impeccable and botch free. The test gets any arrangement bungles all along, making opportunity and money by preventing over the top mistakes and postponements later on. It is doable to perceive issues every step of the way, for instance, part furthest point, part separating, and impression support.

Dissect the improvement materials.

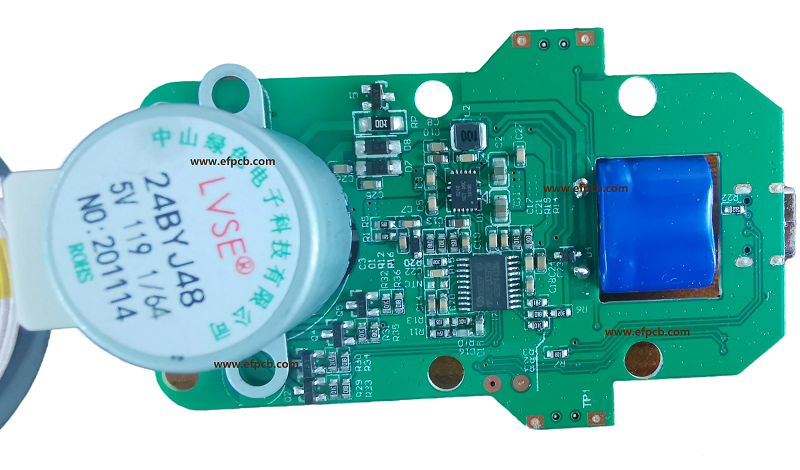

The idea of parts of PCB Assembly China is indispensable. Working with a cultivated PCB developing specialist gives you permission to their quality-control division, which assesses the coming materials. The going with tests ought to be finished to affirm different measures, for instance, the date code, quality, and model number to check expecting they match the BOM.

Test appraisals: Quest for any broke or oxidized pieces as well as any deformation.

Last assessment

A gifted PCB building specialist will do comprehensive checks to guarantee that the PCBs are without screw up and working. Automated optical appraisal (AOI), which uses cameras to find absconds, is constantly used at this point. You can quickly investigate a lot of PCBs with the usage of AOI.

Manual survey is in like manner important for little bunches of PCB Get together, but it requires a lot of venture and work. Additional tests, for instance, in-circuit and utilitarian circuit testing, may be significant for the last assessment.