Focus on the Details of the PCB Fabrication Process

Keywords: PCB Fabrication

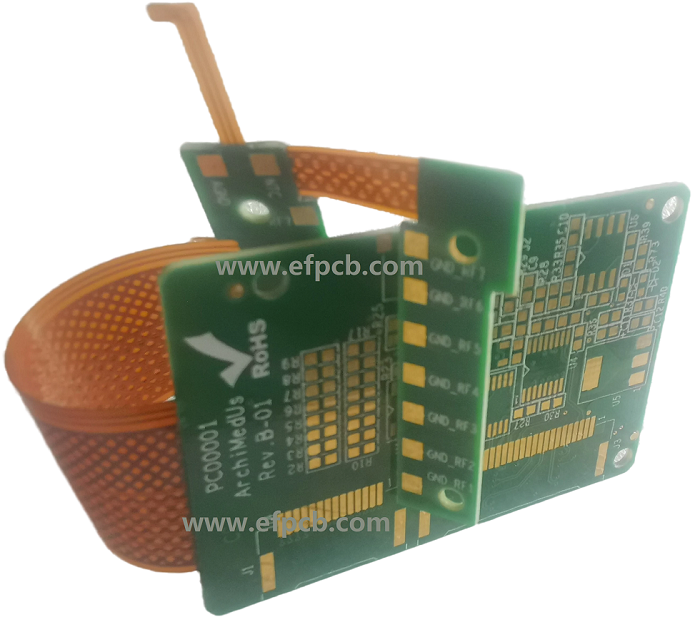

All significant electronics are built upon printed circuit boards. Nearly every computational electronic gadget, including basic ones like digital clocks and calculators, incorporates these amazing achievements. A PCB is a circuit board that sends electrical impulses through electronics to satisfy the needs of the device's electrical and mechanical circuits, for individuals who lack technical understanding. In other words, PCBs direct the flow of electricity, which activates your electronics. Thus, PCB Fabrication is an essential process.

PCBs use a network of copper routes to conduct electricity across their surface. Each component of a PCB circuit board has a specific function that is determined by the intricate system of copper pathways.

Before beginning PCB design, it is advised that circuit designers visit a PC board facility and speak with fabricators face-to-face about their PCB production requirements. It assists in preventing the transmission of any unneeded mistakes made by designers throughout the design phase. This, however, becomes impractical as more businesses outsource their inquiries about PCB production to foreign providers. Due to this, we are presenting this article to help readers understand the stages involved in producing PCB boards. Hopefully, it will provide a clear understanding of how printed circuit boards are made so that circuit designers and people new to the PCB industry may avoid making those unneeded mistakes.

Numerous issues with your PCB development process might arise from not paying enough attention to the quality of your boards' construction. These can include the inability to build your boards, low yield rates, or even field failures that occur too soon. However, there are ways that design decisions might reduce the need for these time-consuming and expensive contingencies.

What is the procedure for fabricating PCBs?

Jumping into fabrication without understanding the linkages and processes between the schematic or concept you have in mind and having it manufactured may not be beneficial. It can be beneficial to explain a few more terminology and how they relate to PCB manufacturing before moving on.

PCB development is the process of moving a circuit board design from the design stage to the production stage.

Typically, there are three steps involved in this: design, production, and testing.

Except for the simplest designs, this approach is iterative to produce the greatest quality design in the allocated amount of time.

PCB Production: Your board design is constructed via PCB fabrication. Board manufacturing is the first phase in this two-step process, and printed circuit board assembly is the latter step (PCBA).

Testing PCBs: The third step of PCB development, known as bring-up or testing, takes place after production. Testing is done during development to assess the board's capability to carry out the operational functionality that is envisaged. Any mistakes or locations where the design has to be changed to improve performance are found during this phase, and a new cycle is started to include the design modifications.

PCB Assembly: The second stage of PCB production, often known as PCB assembly or PCBA, involves connecting the board components to the bare board.

What is the procedure for PCB manufacture in light of this?

The Process of Making PCBs

Using the parameters included in the design package, PCB manufacturing is the process or operation that converts a circuit board design into a physical structure. The acts or methods described below are used to bring about this physical manifestation:

- Visualization of the intended arrangement on copper-clad laminates

- To show traces and pads, etching or removing extra copper from inner layers is necessary.

- By laminating (heating and pressing) board materials at high temperatures, the PCB layer stack up is produced.

- drilling holes for vias, through-hole pins, and mounting holes

- To show traces and pads, etching or removing extra copper from the surface layer(s) is required.

- via holes and pin holes for plating

- Adding a protective coating to the solder masking or surface

- reference and polarity indications, logos, and other surface marks by silkscreen printing

- Adding a finish is an option for copper-surfaced spaces.

Let's examine the implications of this information for PCB development now.

Is Knowledge of the PCB Fabrication Process Important?

Is it crucial to comprehend the PCB fabrication process? This is a question that may and probably should be posed. After all, PCB manufacturing is a contract manufacturer's outsourced job and is not a design activity (CM). Although fabrication is not a design process, it is nonetheless carried out exactly according to the instructions you provide your CM.

Most of the time, your CM is not aware of the purpose of your design or your performance objectives. As a result, they would not be aware of whether you are choosing wisely when it comes to the following board variables, which are established during fabrication and may affect your PCB's ability to be manufactured, its manufacturing yield rate, or its performance after deployment:

Manufacturability: A variety of design decisions will affect how easily your boards can be manufactured. Among these include making sure that there are appropriate distances between surface elements and the board edge and that the material used has a high enough coefficient of thermal expansion (CTE) for no-lead soldering to survive PCBA. Either of them might make it impossible to construct your board without redesigning it. Additionally, if you wish to penalize your designs, that will also require planning.

Rate of yield: Your board can be successfully made, however, there are fabrication problems. For instance, choosing specifications that push the equipment's tolerance limits might lead to a higher-than-acceptable proportion of useless boards.

Reliability: Your board is categorized by IPC-6011 depending on the intended use. There are three categorization levels for stiff PCBs, each of which establishes certain requirements for the design of your board to attain a given degree of performance reliability. Your board will probably operate inconsistently or fail before it should if it is constructed to a lesser classification than what your application demands.

Although not all-inclusive, the examples above show the kinds of issues you could run into if suitable fabrication specification choices are not taken during design.

So, a resounding yes is the appropriate response! Understanding the PCB manufacturing process is crucial because the design decisions you make at this point can have an impact on PCB development, production, and even operation. Using design for manufacturing (DFM) principles and standards that are based on the capabilities of your CM is your greatest line of defense against the kinds of issues that might arise from not including knowledge of the PCB fabrication process in your design decisions.