Flexible PCB Prototyping: Giving Life to Designs

Keywords: Flexible PCB

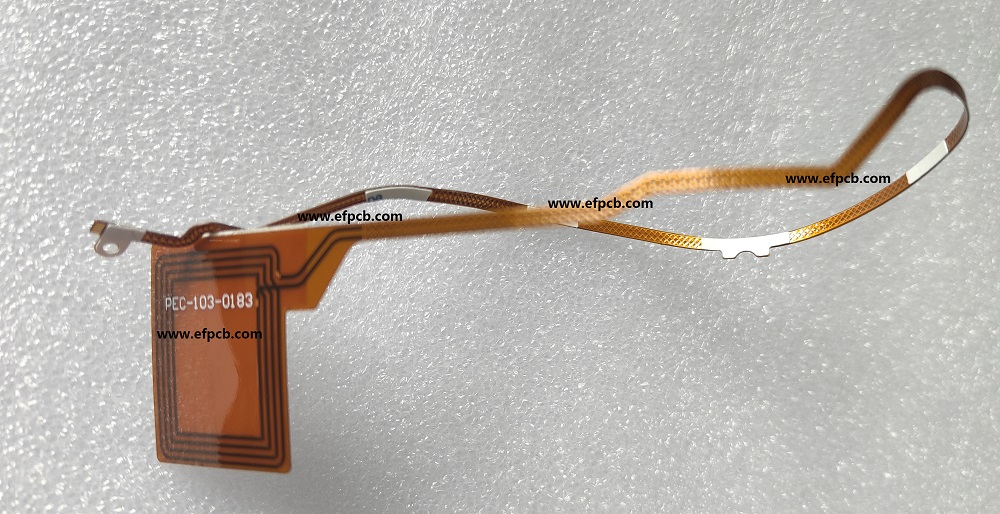

In the dynamic world of electronics, innovation is the name of the game. Engineers and designers are continually seeking new ways to enhance the performance and functionality of electronic devices while minimizing size and weight. One of the most remarkable developments in this field is the rise of flexible printed circuit boards (PCBs). These flexible PCB, often referred to as FPCs or flex PCBs, offer a unique solution for applications where traditional rigid PCBs fall short.

Flexible PCBs are characterized by their adaptability, making them perfect for applications that require intricate designs, lightweight construction, and the ability to bend or conform to non-standard shapes. However, creating a flexible PCB design that meets all these criteria can be a complex task. To ensure success, engineers and designers often turn to flexible PCB prototyping to test their designs before mass production.

In this blog, we will explore the exciting world of flexible PCB prototyping, examining its importance, methods, and benefits. We will delve into the essential steps that engineers and designers need to take to turn their concepts into tangible prototypes and why this process is crucial for the electronics industry.

The Significance of Flexible PCB Prototyping

Prototyping is an integral part of the product development cycle. In the context of flexible PCBs, prototyping is particularly essential due to the unique challenges posed by flexible materials and designs. Here are some of the key reasons why engineers and designers opt for flexible PCB prototyping:

Design Validation: Prototyping allows engineers and designers to validate their flexible PCB designs, ensuring they function as intended. It helps identify and rectify any design flaws before committing to mass production, saving time and resources.

Material Selection: Choosing the right flexible PCB materials is vital for the success of a project. Prototyping enables testing of different materials and their suitability for specific applications, ensuring the best choice is made.

Performance Testing: Flexible PCBs are used in a wide range of applications, from wearable devices to medical equipment. Prototyping permits rigorous testing of the PCB's performance under various conditions, including stress, bending, and temperature variations.

Cost Reduction: Detecting design or functionality issues at the prototype stage can prevent costly mistakes during mass production. It allows for refinements in the design, reducing the risk of having to scrap or rework a large quantity of boards.

Flexible PCB Prototyping Methods

There are several methods available for prototyping flexible PCBs, each with its advantages and limitations. The choice of method depends on factors such as budget, project timeline, and the complexity of the design. Here are three common methods for flexible PCB prototyping:

PCB Manufacturers: Many PCB manufacturers offer prototyping services for flexible PCBs. This approach is ideal for designs that closely resemble traditional rigid PCBs and require minimal customization. Engineers can submit their design files, and the manufacturer will produce a small batch of prototypes for testing.

Rapid Prototyping Services: Rapid prototyping services specialize in creating prototypes quickly and efficiently. These services are equipped with advanced machinery that can produce flexible PCBs with intricate designs and features. While they may be more expensive than traditional PCB manufacturers, they offer speed and expertise.

Steps in Flexible PCB Prototyping

Prototyping flexible PCBs involves a series of well-defined steps to ensure a successful outcome. Let's break down the process:

Concept and Design: The journey begins with the concept and design phase, where engineers and designers define the project's objectives, outline specifications, and create a preliminary PCB design. At this stage, it's essential to consider the application's requirements, such as size, flexibility, and performance.

Material Selection: Choose the appropriate flexible PCB materials based on the design requirements. Flexible PCBs can be made from various materials, including polyimide (PI) and polyester (PET). The material selection should align with the PCB's expected performance and environmental conditions.

Design Software: Use specialized PCB design software to create the flexible PCB layout. The software allows you to define the circuit connections, component placement, and overall design. Ensure that the software supports flexible PCB design, as it may have different requirements than rigid PCBs.

Prototyping Method Selection: Decide on the prototyping method that best suits your project. Depending on factors like budget and design complexity, choose between a PCB manufacturer, DIY prototyping, or rapid prototyping services.

Design Review: Before moving forward, conduct a comprehensive design review to catch any errors, inconsistencies, or issues in the design. This step is vital to avoid costly mistakes during prototyping and production.

Fabrication: Submit the design files to the selected prototyping service or manufacturer. They will create the flexible PCB using the chosen materials, components, and manufacturing techniques. Make sure to specify any special requirements or testing parameters.

Assembly: Assemble the prototype by attaching components to the flexible PCB. The components should be selected to match the design's intended use. Carefully solder or mount the components onto the board.

Testing and Evaluation: Rigorously test the prototype under various conditions to ensure it meets the design specifications. This includes electrical testing, flexibility testing, and performance testing.

Iteration: If any issues or improvements are identified during testing, go back to the design phase and make the necessary revisions. Prototyping allows for multiple iterations until the design is perfected.

Benefits of Flexible PCB Prototyping

The advantages of flexible PCB prototyping are numerous and far-reaching, making it a fundamental step in the development of modern electronic devices. Here are some of the key benefits:

Risk Mitigation: Prototyping helps identify and mitigate potential risks early in the design process. It reduces the likelihood of costly errors or redesigns during mass production.

Design Optimization: Engineers and designers can fine-tune their designs and ensure they meet performance and functionality requirements through multiple iterations.

Time and Cost Savings: By addressing issues and refinements in the prototype stage, you can avoid time-consuming and expensive setbacks in the later stages of production.

Customization: Flexible PCBs are often used in applications that demand custom shapes and configurations. Prototyping allows for the creation of tailored solutions that cater to specific design requirements.

Market Readiness: Successful prototyping accelerates the time-to-market for new products, giving businesses a competitive edge in the fast-paced electronics industry.

Conclusion

Flexible PCB has revolutionized the electronics industry, offering a level of adaptability and performance that was previously unimaginable. However, achieving success with flexible PCB designs necessitates careful planning, material selection, and testing. Flexible PCB prototyping is the linchpin in this process, providing engineers and designers with the opportunity to validate their designs, reduce risks, and optimize their creations. By following the steps outlined in this blog and leveraging the benefits of flexible PCB prototyping, the electronics industry is better equipped to embrace the future of flexible and wearable technologies, medical devices, aerospace applications, and countless other innovative fields. With the right approach and tools, engineers and designers can bring their creative visions to life and push the boundaries of what is possible in the world of flexible electronics.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact