Flexible PCB Manufacturing Steps

Keywords: Flexible PCB, Flex Circuits Board

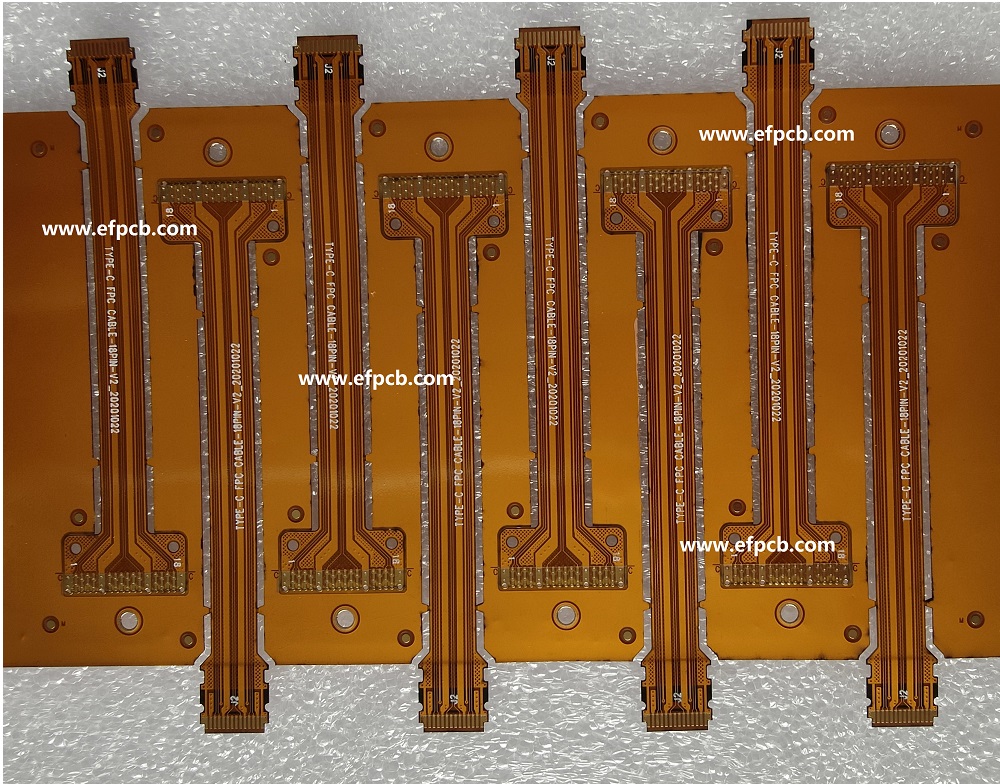

The development of Flexible PCB technology has greatly advanced the capabilities of contemporary electronic devices. Many fragile and sensitive technological gadgets have them at the heart of their design. Many electronic devices, including your smartphone, camera, laptop, calculator, and many more, use this technology.

Describe Flexible PCB

It is constructed using polyimide as the foundation substrate material. This substance, which may be found both naturally and artificially, is employed in a variety of sectors, including the automotive and apparel industries. When compared to conventional rigid printed circuit boards, flexible circuits' small size and high electrical connection density give us significant weight, space, and cost benefits. When used in the appropriate application, this technology may save the overall cost of electrical hookups by up to 70% and the amount of wiring used by up to 75%.

Due to its outstanding benefits, such as its flexible construction, small volume, and lightweight, suitable with the trend toward downsizing in electronics development, flexible PCB is growing and receiving a wide variety of applications. In addition to dynamic flexibility, curling, and folding, flexible PCBs may also incorporate static flexibility. Flexible PCBs increase the degree of flexibility in mechanical and circuit design by stretching into three dimensions. Additionally, by tracing on X, Y, and Z surfaces with fewer connections, machine work and assembly mistakes may be reduced, and the reliability and stability of the entire system used by electronic devices can be significantly increased. Flexible PCBs are used extensively in a variety of industries, including computers, communication devices, instruments, medical equipment, aerospace, and the military. Additionally, new application areas for flexible PCBs such as wireless floating heads, repeaters, digital cameras, mobile phones, flat panel displays, and HDI PCBs have significantly fueled the growth of flexible PCBs and increased their share of the overall PCB market.

Design of Flexible PCB

Flexible PCBs can be divided into the following groups based on structural types:

- Single-side flexible PCB, which is readily fabric table and has a straightforward construction

- Double-sided flexible PCB has a more complex structure than single-sided flexible PCB and is more difficult to regulate

- Multi-layer flexible PCB, which has a more intricate structure than 2-layer flexible PCB and is more challenging to fabricate with consistent quality

- Rigid-flexible PCB with a single side

- PCB with a double-side rigid-flexion

- PCB with several rigid-flex layers

The first three varieties of flexible PCBs—single-side, double-side, and multi-layer rigid-flex—are more challenging to construct because they have significantly more intricate architectures.

Flexible PCB Material

According to the flexible PCB's construction, the insulating substrate material, adhesive, metal conductor layer (copper foil), and cover layer are the ingredients that make up the flexible PCB. The flexible insulating film, which serves as a carrier and has great mechanical and electrical performance, must be the primary component of flexible PCBs. Polyester and polyimide film are common materials, with the latter being used more frequently. Other types of substrate materials, such as PEN and thin FR4, are now accessible in addition to the standard materials due to the continued research and development of new materials. The remainder of this article will walk you through the steps involved in producing Flex Circuits Board.

Flex Circuit Board Manufacturing Process in Detail

The manufacturing process is organized and methodical. Let's examine three crucial production processes:

STEP 1: Flex PCB Build Up

The initial phase is when the preservation of the basic material is the major objective. Polyimide is the main material utilized for the flex circuit. In comparison to FR-4, this material is more costly, and it must be utilized correctly. Circuits should be kept as near to one another as feasible utilizing the nesting method for proper polyimide utilization. The following procedures are used in the fabrication of prototype PCBs:

Looping: It's okay to add a little bit of excess content over the designer's maximum. The servicing length and circuit assembly are made possible by this additional material, sometimes referred to as a service loop.

Size of conductor: Because it offers the most flexibility, you should choose the thinnest copper possible, especially if you want to utilize the circuit for dynamic applications.

Etching: This procedure is used to make up for any isotropic losses that may have occurred during manufacture. The line width loss during this operation is approximately twice as great as the thickness of the copper foil. The line width is affected by several variables, including the conductor, various copper kinds, and etches masks.

Routing: The wires may be simply routed. Just arrange yourself so that you are parallel to the curve and fold. Lowering stress will enhance folding and bending.

Create crosshatched ground regions if the electrical allotment is sufficient. Lowering the weight of the circuit board helps the circuit's flexibility.

STEP 2: Flexible Printed Circuit Board (PCB) Manufacturing Process

Let's now concentrate on the boards. The conductor width and spacing come first. 375 micrometers is the minimum conductor width needed for polymer thin films. The desired proportion of circuit current is carried by both the nominally thick polymer films and the silver-based polymer films simultaneously. Depending on the design and use, the diameter of the holes on flexible PCBs might change.

Size of the holes: The manufacturer can design small holes and a PCB architecture that is well-inclined to flexibility. With modern technology, it is feasible to create holes as small as 25 micrometers.

Filleting is a method that allows you to split the stress and multiply the pad's surface area. You must fillet all of the pads and land termination locations on your flexible circuits. To make a solid solder junction, plated through holes are the best choice. Button plating: In this case, a replacement plated through-hole can be made. Copper is used by manufacturers to prepare vias and through-holes.

Step 3: Pay close attention to physical limitations

Manufacturers deal with cover layer and cover coating issues in this procedure. We provide you a few typical process cover layers:

Films with adhesive backing given that it is made of raw materials are suitable for dynamic flex circuit applications. The majority of the time, adhesive-backed films are utilized to cover bespoke PCBs.

Screen-printable liquid overcoats: Screen-printable liquid overcoats are often employed with thick polymer films and are cost-effective.

A liquid and film polymer that can be used in photography. It is the most sophisticated over-coating technique and includes several unexpected features like:

- It serves as a solder mask and keeps solder from shorting out the traces.

- It guards against internal and external damage to the printed circuits.

- It stops circuits from becoming externally electrified.

- Flexible PCBs distinguish themselves from other traditional solutions by providing a diversity of connectivity and dependability.

Keywords: Flexible PCB, Flex Circuits Board

The development of Flexible PCB technology has greatly advanced the capabilities of contemporary electronic devices. Many fragile and sensitive technological gadgets have them at the heart of their design. Many electronic devices, including your smartphone, camera, laptop, calculator, and many more, use this technology.

Describe Flexible PCB

It is constructed using polyimide as the foundation substrate material. This substance, which may be found both naturally and artificially, is employed in a variety of sectors, including the automotive and apparel industries. When compared to conventional rigid printed circuit boards, flexible circuits' small size and high electrical connection density give us significant weight, space, and cost benefits. When used in the appropriate application, this technology may save the overall cost of electrical hookups by up to 70% and the amount of wiring used by up to 75%.

Due to its outstanding benefits, such as its flexible construction, small volume, and lightweight, suitable with the trend toward downsizing in electronics development, flexible PCB is growing and receiving a wide variety of applications. In addition to dynamic flexibility, curling, and folding, flexible PCBs may also incorporate static flexibility. Flexible PCBs increase the degree of flexibility in mechanical and circuit design by stretching into three dimensions. Additionally, by tracing on X, Y, and Z surfaces with fewer connections, machine work and assembly mistakes may be reduced, and the reliability and stability of the entire system used by electronic devices can be significantly increased. Flexible PCBs are used extensively in a variety of industries, including computers, communication devices, instruments, medical equipment, aerospace, and the military. Additionally, new application areas for flexible PCBs such as wireless floating heads, repeaters, digital cameras, mobile phones, flat panel displays, and HDI PCBs have significantly fueled the growth of flexible PCBs and increased their share of the overall PCB market.

Design of Flexible PCB

Flexible PCBs can be divided into the following groups based on structural types:

- Single-side flexible PCB, which is readily fabric table and has a straightforward construction

- Double-sided flexible PCB has a more complex structure than single-sided flexible PCB and is more difficult to regulate

- Multi-layer flexible PCB, which has a more intricate structure than 2-layer flexible PCB and is more challenging to fabricate with consistent quality

- Rigid-flexible PCB with a single side

- PCB with a double-side rigid-flexion

- PCB with several rigid-flex layers

-

The first three varieties of flexible PCBs—single-side, double-side, and multi-layer rigid-flex—are more challenging to construct because they have significantly more intricate architectures.

Flexible PCB Material

According to the flexible PCB's construction, the insulating substrate material, adhesive, metal conductor layer (copper foil), and cover layer are the ingredients that make up the flexible PCB. The flexible insulating film, which serves as a carrier and has great mechanical and electrical performance, must be the primary component of flexible PCBs. Polyester and polyimide film are common materials, with the latter being used more frequently. Other types of substrate materials, such as PEN and thin FR4, are now accessible in addition to the standard materials due to the continued research and development of new materials. The remainder of this article will walk you through the steps involved in producing Flex Circuits Board.

Flex Circuit Board Manufacturing Process in Detail

The manufacturing process is organized and methodical. Let's examine three crucial production processes:

STEP 1: Flex PCB Build Up

The initial phase is when the preservation of the basic material is the major objective. Polyimide is the main material utilized for the flex circuit. In comparison to FR-4, this material is more costly, and it must be utilized correctly. Circuits should be kept as near to one another as feasible utilizing the nesting method for proper polyimide utilization. The following procedures are used in the fabrication of prototype PCBs:

Looping: It's okay to add a little bit of excess content over the designer's maximum. The servicing length and circuit assembly are made possible by this additional material, sometimes referred to as a service loop.

Size of conductor: Because it offers the most flexibility, you should choose the thinnest copper possible, especially if you want to utilize the circuit for dynamic applications.

Etching: This procedure is used to make up for any isotropic losses that may have occurred during manufacture. The line width loss during this operation is approximately twice as great as the thickness of the copper foil. The line width is affected by several variables, including the conductor, various copper kinds, and etches masks.

Routing: The wires may be simply routed. Just arrange yourself so that you are parallel to the curve and fold. Lowering stress will enhance folding and bending.

Create crosshatched ground regions if the electrical allotment is sufficient. Lowering the weight of the circuit board helps the circuit's flexibility.

STEP 2: Flexible Printed Circuit Board (PCB) Manufacturing Process

Let's now concentrate on the boards. The conductor width and spacing come first. 375 micrometers is the minimum conductor width needed for polymer thin films. The desired proportion of circuit current is carried by both the nominally thick polymer films and the silver-based polymer films simultaneously. Depending on the design and use, the diameter of the holes on flexible PCBs might change.

Size of the holes: The manufacturer can design small holes and a PCB architecture that is well-inclined to flexibility. With modern technology, it is feasible to create holes as small as 25 micrometers.

Filleting is a method that allows you to split the stress and multiply the pad's surface area. You must fillet all of the pads and land termination locations on your flexible circuits. To make a solid solder junction, plated through holes are the best choice. Button plating: In this case, a replacement plated through-hole can be made. Copper is used by manufacturers to prepare vias and through-holes.

Step 3: Pay close attention to physical limitations

Manufacturers deal with cover layer and cover coating issues in this procedure. We provide you a few typical process cover layers:

Films with adhesive backing given that it is made of raw materials are suitable for dynamic flex circuit applications. The majority of the time, adhesive-backed films are utilized to cover bespoke PCBs.

Screen-printable liquid overcoats: Screen-printable liquid overcoats are often employed with thick polymer films and are cost-effective.

A liquid and film polymer that can be used in photography. It is the most sophisticated over-coating technique and includes several unexpected features like:

- It serves as a solder mask and keeps solder from shorting out the traces.

- It guards against internal and external damage to the printed circuits.

- It stops circuits from becoming externally electrified.

- Flexible PCBs distinguish themselves from other traditional solutions by providing a diversity of connectivity and dependability.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact