Flex PCBs are Chosen for Different Applications

Keywords: Flexible PCB, Flexible PCB Manufacturer

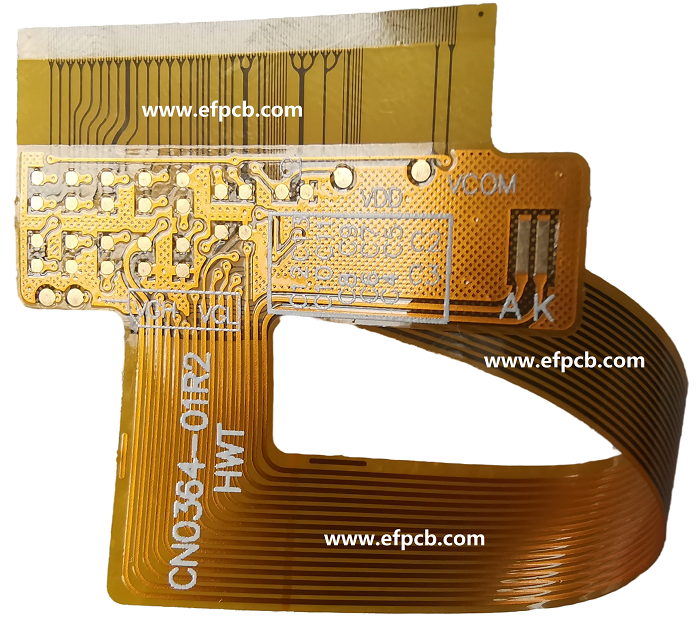

Adaptable circuit sheets, or Flexible PCB, have incredibly dainty substrates, high levels of bendability and rigidity, and are genuinely adaptable. They may likewise be shaped into unpredictable three-layered structures for various purposes, remembering up front consoles for pilots for the aeronautic trade, wearable hardware, and small gadgets for clinical purposes.

Indeed, even materials as slight as a couple of microns might be dependably carved on flex PCBs. This, along with the benefit of getting rid of traditional wiring bridles and strip associations, some of the time makes them desirable over unbending PCBs in unambiguous circumstances.

Flex PCBs additionally open up a few substantial plan benefits, for example,

• Complete adaptability.

• Better resilience than aggravations from vibrations and different variables in testing circumstances.

• Support for minimized, light-weight plan; significant decrease in item weight.

• Links that are more minimized and adaptable than standard wires.

• The ability to be twisted or contorted without bringing on any harm.

Flex PCBs from Flexible PCB Maker give equivalent advantages according to a creation viewpoint. Contrasted with numerous other PCBs, they give unrivaled ventilation and intensity dispersal. Their inadequate quantities of associations and parts additionally convert into much-decreased gathering costs than those for traditional wire outfits. Furthermore, since the creation cycle is rearranged and normalized, without the irksome hand input important for making a large number of these saddles, there is decreased in general weakness to gathering deficiencies.

Why Pick Flex PCBs All things considered?

In certain circumstances, flex associations likewise have better science than customary strip links, as well as having mechanical advantages over them in various applications.

With branches to a few associations, a flex circuit might be made in many-sided three-layered plans that are unattainable with a strip wire. Flex circuits may likewise associate with solid sheets without the generally enormous and awkward associations level wires need, or on account of inflexible flex plan, they can be incorporated into the actual sheets, getting rid of the requirement for outer connectors altogether. Flex circuits' guide thickness can be a lot higher than that of strip links too.

Past the various clear contrasts, flex circuits enjoy a couple of minor upper hands over customary lace wires. Kapton, one of the materials every now and again utilized for Adaptable PCB, has extraordinarily little outgassing in circumstances with very high vacuum, like space.