Flex Circuit Boards: Unleashing the Power of Bendable Electronics

Keywords: Flex Circuits Board

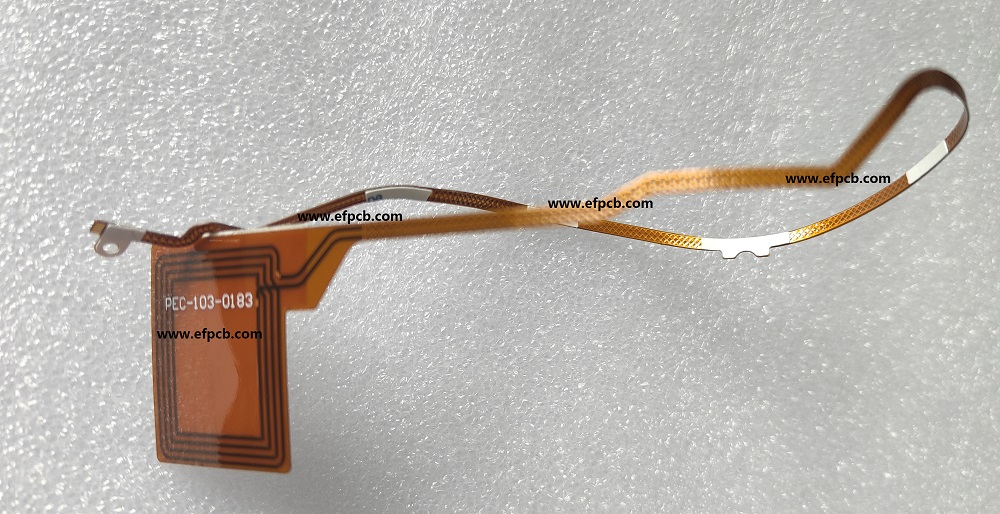

Flex circuit boards, also known as flexible printed circuit boards or flex PCBs, are a type of electronic interconnect technology that allows for circuitry to be printed on flexible substrates. Unlike traditional rigid circuit boards, flex PCBs are made of flexible materials like polyimide or polyester. These materials provide excellent mechanical strength while allowing for flexibility and bending.

Applications of Flex Circuit Boards:

Flex circuit boards have found applications in a wide range of industries, including:

- Automotive: Flex PCBs are extensively used in automotive applications. They can be integrated into various components such as instrument clusters, dashboard controls, sensors, and lighting systems. The flexibility of these circuits enables space-saving designs and improved reliability in harsh automotive environments.

- Medical Devices: Flex circuit boards have revolutionized the medical field. They are used in devices like pacemakers, hearing aids, medical implants, and diagnostic equipment. The ability to create thin, lightweight, and flexible medical devices has transformed patient comfort and improved healthcare outcomes.

- Aerospace and Defense: In the aerospace and defense industries, where weight and space constraints are critical, flex circuits offer significant advantages. They are used in satellites, avionics systems, radar systems, and military equipment. Flex PCBs enable the creation of complex, high-density circuits that can withstand extreme conditions.

Benefits of Flex Circuit Boards:

The adoption of flex circuit boards brings several benefits to electronic designs:

- Space Efficiency: Flex PCBs allow for three-dimensional designs, making them ideal for compact and space-constrained applications. The ability to route circuits in different planes and conform to irregular shapes maximizes the use of available space.

- Reliability: Flex circuits have fewer interconnections and solder joints compared to traditional rigid PCBs, reducing the chances of failure due to connection issues. Additionally, their flexible nature allows them to withstand vibrations, shocks, and thermal stresses, increasing overall reliability.

- Weight Reduction: The lightweight nature of flex circuit boards makes them ideal for applications where weight reduction is critical, such as portable devices and aerospace equipment. The use of flexible substrates minimizes the weight of the overall electronic assembly.

- Cost and Time Savings: Flex PCBs can be manufactured using automated processes, resulting in reduced manufacturing costs. Their flexible nature also simplifies assembly processes, leading to faster production cycles and shorter time to market.

NEW ARTICLES

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact