Five Most Normal Blunders of Adaptable Printed Circuit Board Plan

Keywords: Flexible PCB, Flex Circuits Board

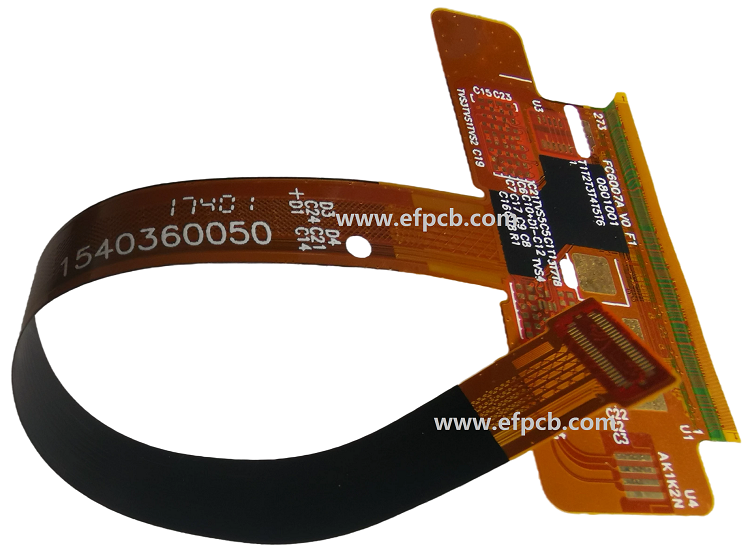

For the electronic originator and bundling engineer, Adaptable Printed Hardware (FPC) offers an enormous open door. Into perpetual layered designs, these flexible electronic wiring frameworks can be collapsed, bowed, molded, and twisted...limited simply by the inventiveness of a specialist. More than a two-layered and unbendable unbending printed circuit board (PCB0, they offer huge plan benefits in such manner. Flexible PCB can be made a plan specialist's fantasy by this additional aspect, however decides that should be followed are related with the option of adaptability to accomplish a specific strong plan.

For FPCs, different assembling material sets and strategies are utilized. The layered properties are a prompt contrast. The standard polyimide film utilized as the structure block in 98% of the flex circuits created versus Inflexible printed circuits is for the most part more correspondingly steady. Requiring different plan rules than its inflexible printed circuit board relative, this expanded layered fluctuation implies an adaptable circuit. Tragically, inflexible PCB configuration rules are utilized by a significant part of the plan programming accessible. For the adaptable circuit, this can make practical and producing issues. Flexing the plan is preparing an adaptable circuit plan for fab in the business.

Five of the more normal flexing ways are recorded underneath that prepare a plan for manufacture, more producible, and more powerful.

Welded joints extremely close to the twist point: By an intermetallic obligation of the bind composite to the copper follow, a patch joint is framed. Districts that have been welded become entirely unbendable and inflexible while the copper follow is regularly adaptable. The weld cushion is either going to delaminate or break when the substrate is bowed close to the edge of the patch joint. Serious utilitarian issues will be brought about by one or the other circumstance.

Separating between contiguous follows and weld cushions: plan compromise is the tradeoff here. In view of cover movies or patch veil opening, it will be made. The edges of the contiguous guide follows could be uncovered when the bind veil or cover film openings are made bigger on the off chance that they were directed excessively near a weld cushion. Assuming that patch spans between cushions or connector sticks, this can cause shorts. Another variable that can influence enlistment capacity is the actual size of the circuit. To oblige the bind veil or cover film position resilience, more space is required between a nearby conductive follow and a patch cushion overall.

Cover film openings or Weld veil: After openness to processes like scratching, copper plating, and pumice cleaning, adaptable hardware can show layered change during manufacture. To oblige ensuing enlistments for bite the dust cutting, stiffeners, or cover film, Flex Circuits Board configuration manages for the most part require bigger resistances while certain progressions can be represented. For the cement press out that happens, extra thought is expected during the overlay of the cover film dielectric. The heap of groupings and cycles expected to deliver a custom adaptable circuit is muddling the forecast of remunerating configuration highlights. For the most part expected to permit more space in a flex circuit plan, the main concern is the openings in the cover film.

Stacked follows: Follows on inverse dielectric sides shouldn't stack straightforwardly on one another. On the off chance that they adjust in equal straightforwardly with a follow on the contrary side, follows in pressure outwardly of the curve span might get broken when the circuit is twisted. Farther from the nonpartisan pivot of the collapsed district, the follows in strain are constrained and can get cracked, particularly with continued twisting. By planning this district as a solitary conductive layer, keeping the copper in the nonpartisan hub of a curve is a decent plan practice. To forestall base and top arrangement, a legitimate plan will stun the follows between the base and top copper layers when this is preposterous.

Guides' Emphasize focuses: Issues in an adaptable circuit might be made by follow setups that are satisfactory in an unbending PCB as flex hardware is utilized in both crease to dynamic and introduce flexing applications. Whenever the region close to them is flexed, Guide follows with intense crossroads and sharp corners become regular emphasize focuses at the foundation of patch cushions. This can prompt follow delamination or crack. A smooth span for a gentile range and guide turn focuses as opposed to sharp corners from the follow to the cushion filet rather than a sharp point is available in a decent adaptable circuit design. Bowing in bound locales is forestalled by particular connection of stiffeners and is a typical plan practice.

Basically planning a flex circuit, with standard PCB programming, can bring about a few difficult issues in regards to unwavering quality and ability to assemble. To either make the format straightforwardly from a netlist or flex the plan prior to starting manufacture, working with an adaptable circuit plan master or your adaptable circuit provider is ideal. This will guarantee that the made plan will productively address your issues.

The Adaptable PCB Circuit Future

With significantly higher flex layer counts, many new plans are being produced. Those with covered and blind through structures plans with parts mounted into both the adaptable regions and, surprisingly, coordinated ZIF associations, and the unbending segments are remembered for a few additional common plans.

Requiring protecting for Radio Recurrence (RF) or Electromagnetic Impedance (EMI) contemplations, some inflexible flex printed circuit board (PCB) plans might have flex regions. Shifting thicknesses between the awry developments as well as various unbending regions are likewise present in many plans.

Creating interest among OEMs, this article covers a portion of the more normal sorts of blends and designs. For unbending endlessly flex circuit board stack-ups, there are numerous extra mixes and designs accessible. Lopsided developments, safeguarded flex layers, odd layer count developments, coordinated ZIF associations, fluctuating flex layer count plans, air hole flex layer developments, covered and blind vias, and numerous unbending region thicknesses are remembered for the further developed developments.

An exceptionally wide assortment of developments that can add a lot of by and large bundling decrease, plan coordination, and usefulness to a plan has been made by the blend of the present Adaptable PCB and Flexible PCB. To make a practically unending number of flex and unbending flex circuit board arrangements, a large portion of the particular developments that we have surveyed in this specialized article can likewise be joined.