Find out About the Basics of Heat Transfer in A Printed Circuit Board

Keywords: Printed Circuit Board Manufacturer, PCB Manufacturer

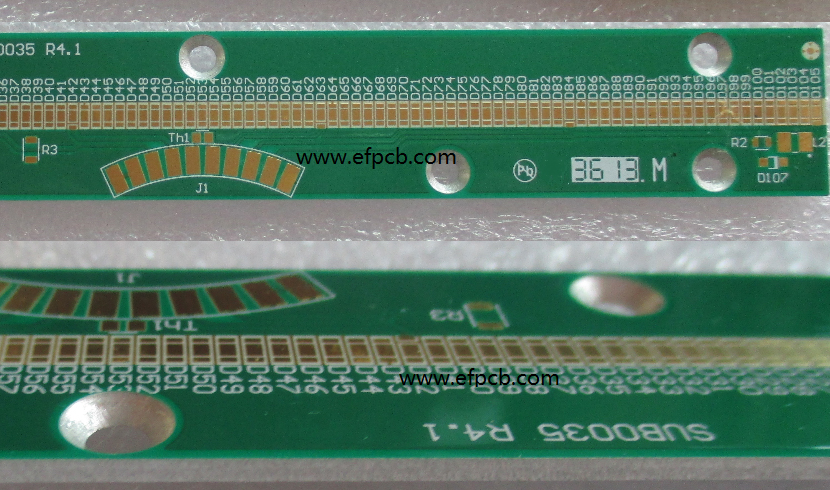

A printed circuit board or PCB is a plate or board that is explicitly utilized for putting the various components that fulfill the guidelines of an electrical circuit that has the electrical interconnections between them.

Today PCB with two layers is the normal one that PCB producer produces and in the two surfaces of the board you can figure out the interconnections.

Essentials of Heat Transfer

On a key level, conversation about heat move incorporates two points: temperature and hotness stream. Temperature demonstrates the degree of nuclear power that is accessible, while heat stream says that nuclear power moves starting with one spot then onto the next.

You will go over hardly any material properties that can tweak heat actually which are being moved between two regions at various temperatures. These are liquid viscosities, warm conductivities, liquid speeds, and material densities. At the point when these properties are consolidated they make the hotness move issue substantially more confounded. Printed Circuit Board Manufacturer is effectively accessible these days.

Interaction of Heat Transfer

In three general classes heat move instruments can be assembled:

Radiation-Every material emits nuclear power in sums that not set in stone by temperature. The radiation transition is in harmony between objects when the temperature is consistent, and no trade of nuclear power is going on.

Conduction-Thermal energy is moved from Areas that have more sub-atomic motor energy to regions that have less sub-atomic energy. This interaction happens through an immediate impact of atoms, known as conduction.

Convection-In an electronic gadget when hotness is created, it's shipped through conduction to an area where it is then moved to a liquid.

Plan Techniques of PCB in Transfer of Heat

Copper pours-In the PCB any part can interface with the ground easily just when the unused regions are loaded up with metal and ground metal.

Warm vias-Thermal vias help in making a pathway to the copper and the PCB parts.

Heat sinks-Large metallic pieces with high conductivity are utilized in this strategy. To the parts that produce heat the pieces are connected accordingly they uncover more surface region to the air. Warm obstruction is brought down through this arrangement, and afterward improvement of hotness stream is finished with a cooling fan.

Higher Thermal Conductivity Materials-In working on the warm conductivity of the PCB Materials like aluminum, pottery, and copper center are utilized. Today PCB Manufacturing is finished with more prominent effectiveness.