Exploring the Wonders of Microvia PCBs: Revolutionizing Electronics

Keywords: Microvia PCB Companies

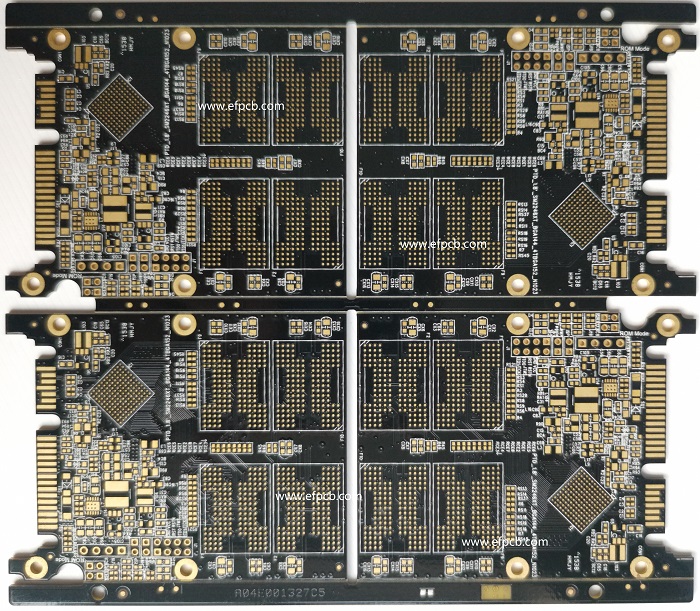

In the ever-evolving world of electronics, innovations continue to drive progress, and one such advancement that has significantly impacted the field is the Microvia Printed Circuit Board (PCB). As technology demands smaller, lighter, and more efficient electronic devices, Microvia PCBs have emerged as a crucial player in meeting these requirements. In this blog, we'll delve into the intricacies of Microvia PCBs, exploring their construction, applications, and the advantages they bring to the electronics industry.

Understanding Microvia PCBs :

Microvia PCBs represent a leap forward in miniaturization and performance. Unlike traditional PCBs, which utilize drilled holes for interconnecting layers, Microvia PCBs incorporate microvias—tiny, laser-drilled holes with diameters typically less than 150 micrometers. These microscopic holes enable the creation of more complex and compact circuitry, making them ideal for densely populated electronic devices.

Construction and Types of Microvias :

Blind Microvias :

These microvias connect an outer layer to one or more inner layers without penetrating the entire board.

Ideal for achieving high-density interconnections in a limited space.

Buried Microvias :

Located within the inner layers of the PCB, buried microvias connect different internal layers without reaching the outer surfaces.

Enhances the PCB's overall routing capabilities while maintaining a clean and unobstructed exterior.

Through Microvias :

Penetrate the entire PCB, connecting both outer and inner layers.

Offer a comprehensive solution for achieving intricate connections throughout the entire board.

Applications of Microvia PCBs :

Consumer Electronics:

Microvia PCBs play a crucial role in the development of smartphones, tablets, smartwatches, and other portable devices where space is a premium.

Medical Devices:

In the medical field where miniaturization is often essential, Microvia PCBs contribute to the design of compact and high-performance medical devices.

Automotive Electronics:

As vehicles become more technologically advanced, Microvia PCBs enable the creation of compact and reliable electronic systems within automotive applications.

Aerospace and Defense:

Microvia PCBs are well-suited for aerospace and defense applications where lightweight and compact electronic systems are critical.

Advantages of Microvia PCBs :

Miniaturization:

Microvia technology allows for the creation of smaller and lighter electronic devices, promoting miniaturization without compromising functionality.

Improved Signal Integrity:

The reduced size of microvias minimizes signal loss and impedance issues, contributing to enhanced signal integrity in high-frequency applications.

Increased Density:

Microvia PCBs enable higher component density, facilitating the design of more complex circuits within a limited space.

Enhanced Reliability:

The precise manufacturing processes involved in creating microvias contribute to improved reliability, as there is less room for errors and defects.