Exploring the Benefits of Flexible PCBs in Modern Design

Keywords: Flexible PCB, Flexible PCB Manufacturer

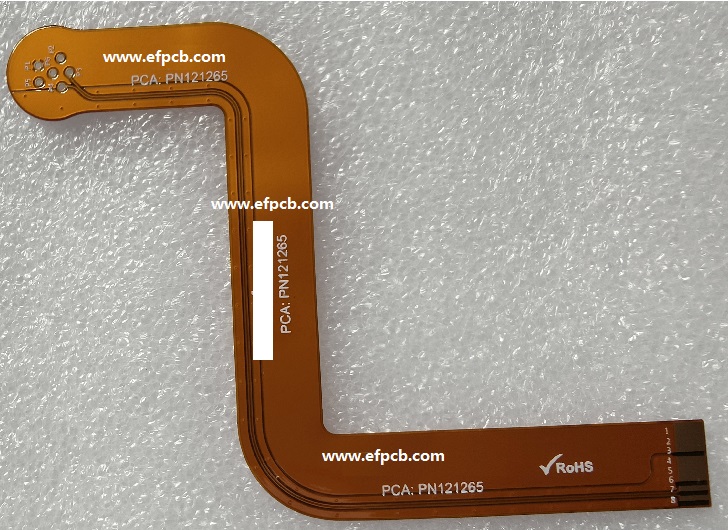

Flexible PCB, also known as a flex circuit, is a type of printed circuit board that offers flexibility and versatility in design. These boards are made from a flexible plastic substrate material that allows them to bend and twist in various configurations, making them ideal for use in applications that require a high degree of flexibility.

Flexible PCBs are commonly used in a variety of industries such as aerospace, automotive, consumer electronics, medical devices, and telecommunications. They are particularly useful in applications where space is limited, and weight is a concern. Due to their thin, lightweight design, they can be bent or folded to fit into tight spaces or unusual shapes, making them an ideal choice for products with unique form factors.

The manufacturing process for Flexible PCB is different from traditional rigid PCBs. The flexible plastic substrate is coated with a thin layer of copper, which is then etched to create the desired circuitry pattern. Unlike rigid PCBs, the substrate is not removed, allowing the board to remain flexible.

One of the main benefits of flexible PCBs is their ability to reduce the number of interconnects required in a system. Since they can be bent or folded, they can replace multiple rigid boards, reducing the need for connectors and cables. This can result in a more reliable and cost-effective solution for certain applications.

Flexible PCBs also offer improved reliability compared to traditional rigid boards. They can withstand more vibration and shock, as well as extreme temperatures and humidity, and making them a better choice for harsh environments.

Another advantage of flexible PCBs is that they can be produced in higher volumes and at a lower cost compared to rigid boards. This is because they can be manufactured in a single process, reducing the need for multiple layers and interconnects.

In summary, flexible PCBs offer unique benefits compared to traditional rigid PCBs. They can be bent and twisted, reducing the need for connectors and cables, making them ideal for applications with limited space. They also offer improved reliability, are suitable for harsh environments, and can be produced at a lower cost. As technology continues to advance, the use of Flexible PCB is likely to become more widespread in a range of industries.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact