Explore More about the Printed Circuit Boards

Keywords: Printed Circuit Board

In the digital age, we often take for granted the many electronic devices that have become an integral part of our lives. From smartphones to laptops, smart refrigerators to medical equipment, all of these modern marvels have a common component that powers them - the Printed Circuit Board (PCB). This unassuming piece of technology is at the heart of virtually every electronic device, allowing them to function efficiently. In this blog, we will explore the fascinating world of PCBs, uncovering what they are, how they work, and their significance in today's technology-driven world.

What is a Printed Circuit Board (PCB)?

A Printed Circuit Board, often simply referred to as a PCB, is a fundamental component in the world of electronics. It is a flat board made from a non-conductive material, usually fiberglass or a similar substrate, onto which conductive pathways are etched or "printed." These conductive pathways, typically made of copper, form a network of electrical connections that enable the flow of electricity between various electronic components on the board. In essence, PCBs serve as the scaffolding for electronic devices, providing a stable platform for components to be mounted and connected.

How Does a PCB Work?

PCBs work as a critical backbone in electronic devices by providing a reliable and efficient way to connect and interconnect various electronic components, such as microchips, capacitors, resistors, and connectors. Here's how they function:

Electrical Routing: PCBs consist of a complex network of copper traces that are specifically designed to connect different components of the circuit. These traces act as "wires" that carry electrical signals and power throughout the device. The design of these traces is crucial and is determined by the device's intended function.

Component Mounting: Electronic components are soldered onto the PCB. This includes integrated circuits (ICs), transistors, diodes, and various other components. The layout and orientation of these components are meticulously planned to optimize the functionality and efficiency of the device.

Insulation: The non-conductive substrate material of the PCB ensures that electrical connections do not inadvertently short circuit. It also provides a mechanical support structure for the components.

Compact and Space-Efficient: PCBs are designed to be compact, allowing multiple electronic components to be placed in a small space. This compactness is especially vital in the design of portable devices like smartphones and laptops.

Why are PCBs So Important?

Printed Circuit Boards are integral to the world of electronics for several reasons:

Reliability: PCBs enhance the reliability of electronic devices by reducing the risk of loose connections, short circuits, and electromagnetic interference.

Miniaturization: PCBs enable the creation of compact electronic devices by allowing for the placement of components in a highly organized and space-efficient manner.

Scalability: PCBs can be designed for specific applications and scaled up or down as needed, making them adaptable to a wide range of electronic products.

Cost Efficiency: PCBs are mass-produced with automated assembly processes, which significantly reduces production costs.

Ease of Repair: When a PCB fails, it can often be replaced more easily and cost-effectively than individual components on a solderless breadboard.

Standardization: PCBs conform to industry standards, making it easier for engineers and manufacturers to develop and assemble electronic devices.

The Future of Printed Circuit Boards

As technology continues to advance, so too do the possibilities for Printed Circuit Board. Here are some trends and innovations that are shaping the future of PCBs:

Miniaturization: Electronics are getting smaller and more powerful, and PCBs are following suit. Miniaturized components and advanced manufacturing techniques are pushing the limits of how compact PCBs can become. This is essential for wearable technology, IoT devices, and other applications where space is at a premium.

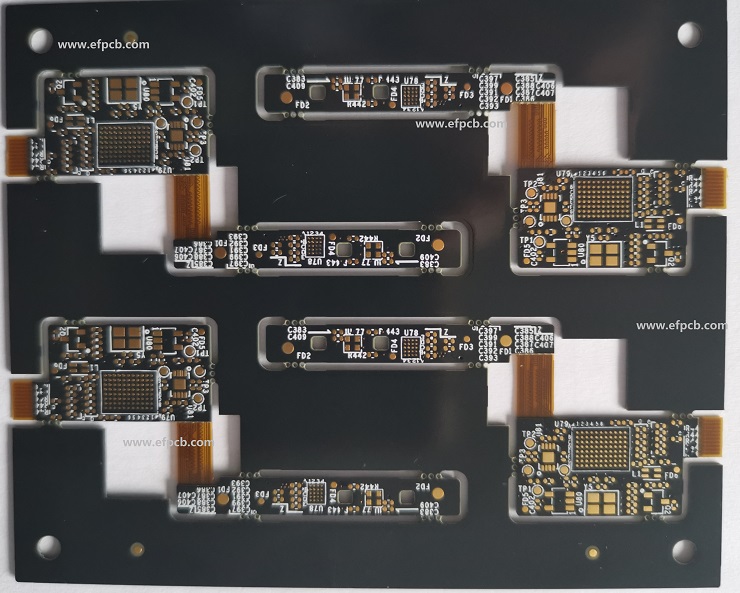

Flexible and Rigid-Flex PCBs: Traditional rigid PCBs are giving way to flexible and rigid-flex PCBs. These designs allow for bending and conforming to the shape of the device, opening up new possibilities for innovative product designs and improved durability.

High-Density Interconnect (HDI) Technology: HDI PCBs feature more intricate and denser wiring patterns. They are crucial for applications like high-speed data transfer, 5G technology, and high-performance computing.

Embedded Components: The integration of components within the PCB itself, known as embedded components or integrated passives, can further reduce the size and weight of electronic devices while improving performance.

Advanced Materials: The development of advanced materials, such as heat-resistant substrates and materials for high-frequency applications, is allowing PCBs to function in a broader range of environments.

Environmental Considerations: PCB manufacturers are increasingly focusing on eco-friendly and recyclable materials. The industry is looking for ways to reduce waste and energy consumption in the production of PCBs.

3D Printing: The adoption of 3D printing for PCBs is on the horizon. This technology could revolutionize PCB prototyping, enabling rapid and cost-effective development of custom circuitry.

AI and Automation: AI is being used in the design, testing, and quality control of PCBs. Automation is streamlining the manufacturing process, reducing errors, and speeding up production.

Wireless Charging: PCBs are at the heart of wireless charging technology, which is becoming more prevalent in consumer electronics. As this technology continues to evolve, PCBs will need to adapt to new power delivery methods.

The Future of Printed Circuit Boards

As technology continues to advance, so too do the possibilities for Printed Circuit Boards. Here are some trends and innovations that are shaping the future of PCBs:

Miniaturization: Electronics are getting smaller and more powerful, and PCBs are following suit. Miniaturized components and advanced manufacturing techniques are pushing the limits of how compact PCBs can become. This is essential for wearable technology, IoT devices, and other applications where space is at a premium.

Flexible and Rigid-Flex PCBs: Traditional rigid PCBs are giving way to flexible and rigid-flex PCBs. These designs allow for bending and conforming to the shape of the device, opening up new possibilities for innovative product designs and improved durability.

High-Density Interconnect (HDI) Technology: HDI PCBs feature more intricate and denser wiring patterns. They are crucial for applications like high-speed data transfer, 5G technology, and high-performance computing.

Embedded Components: The integration of components within the PCB itself, known as embedded components or integrated passives, can further reduce the size and weight of electronic devices while improving performance.

Advanced Materials: The development of advanced materials, such as heat-resistant substrates and materials for high-frequency applications, is allowing PCBs to function in a broader range of environments.

Environmental Considerations: PCB manufacturers are increasingly focusing on eco-friendly and recyclable materials. The industry is looking for ways to reduce waste and energy consumption in the production of PCBs.

3D Printing: The adoption of 3D printing for PCBs is on the horizon. This technology could revolutionize PCB prototyping, enabling rapid and cost-effective development of custom circuitry.

AI and Automation: AI is being used in the design, testing, and quality control of PCBs. Automation is streamlining the manufacturing process, reducing errors, and speeding up production.

Wireless Charging: PCBs are at the heart of wireless charging technology, which is becoming more prevalent in consumer electronics. As this technology continues to evolve, PCBs will need to adapt to new power delivery methods.

Conclusion

Printed Circuit Board is the unsung heroes behind the electronic devices we rely on every day. Their design, layout, and functionality are nothing short of engineering marvels that underpin the technological advances of the modern world. Understanding the importance of PCBs helps us appreciate the intricate web of connections and components that bring our gadgets and appliances to life. As technology continues to evolve, so too will the PCBs that drive it, ensuring the continued growth and innovation of the electronics industry.