Expand Your Knowledge about the IC Substrate

Keywords: IC Substrates

Coordinated circuit substrates or IC Substrates, lately, have shot to noticeable quality. From the development of incorporated circuit types, for example, ball network bundle and chip-scale bundle, it has come about. Something that gets represented by IC substrate, for example, IC bundles call for novel bundle transporters. To comprehend the significance of IC bundle substrate, it no longer demonstrates adequate as a gadgets architect or creator. You need to grasp the IC substrate application regions, the job substrate ICs play in the appropriate working of hardware, and its assembling cycle.

IC Substrate

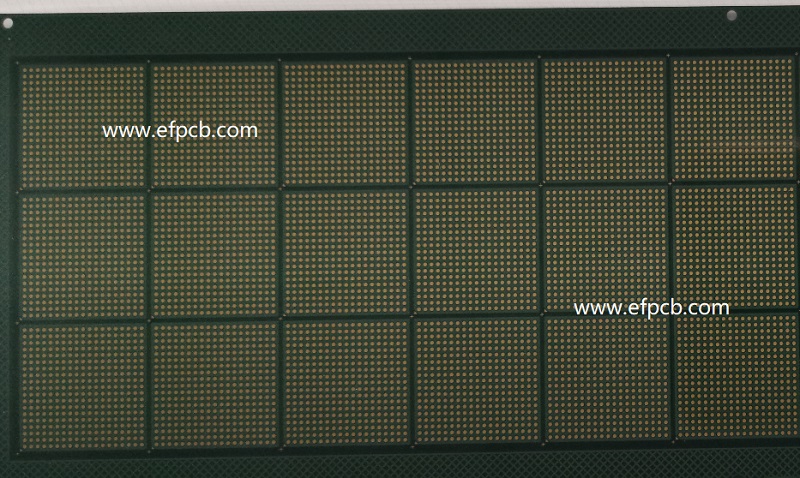

Used in the bundling of exposed coordinated circuit chips, IC substrate is a baseboard type. In associating the circuit board and the chip, the substrate IC demonstrates significant. Under a temporary item catching semiconductor coordinated circuit chip, incorporated circuits fall steering to connect the chip with the PCB. Giving it a warm dissemination burrow, it likewise builds up, supports, and defends the IC chip.

The essential job of connectors of the printed circuit sheets to the semiconductor chip is played by the coordinated circuit substrate. To give interconnect densities, It requires limit on IC fabricators and thus, goes about as the channel. During the IC substrate producing process, this outperforms those of PCB fabricators. In synthetic skill, makers will thusly require arrangements in regards to high-thickness plans and a having demonstrated claim to fame. Coordinated circuit substrates fall under various groupings and are different.

Material that contains the semiconductor gadget is alluded to as IC bundling. Other than taking into consideration mounting of electrical reaches, it safeguards it against consumption or actual harm as a bundle is encasing the IC substrate. In associating the electrical contacts to the PCB, It is particularly imperative. Different coordinated circuits bundling frameworks configuration types exist. As each has unmistakable necessities in the question of their external shell, Contemplations for these changed kinds become fundamental.

IC Bundling

In semiconductor gadgets creation, it frequently comes as the last step. Safeguarding the incorporated circuit from age-related erosion or hindering outer components, the semiconductor gets a packaging at this stage. Other than advancing electrical contacts, the packaging by configuration safeguards the block. To an electronic gadget's circuit board, this conveys signals.

At the point when they became well known among EPMs, the IC bundling tech developed from the BGA bundles of the 1970s. Be that as it may, fresher choices and variants eclipsed pin network cluster bundles from the beginning of the 21st 100 years. The plastic quad level pack and little slender layout bundles are remembered for such advancements. Like the FCBGA, further developed bundling innovations right now exist. This is an up-degree of the bundles of the land matrix exhibit.

Plans of IC Substrates bundling

In view of development, IC bundling plans additionally have numerous classifications. It incorporates the lead-outline type and substrate type. Other optional classification structures exist while the two structure the essential order of IC bundling plans. You will see as the accompanying here.

Lead-outline and Double inline bundles: For congregations that expect pins to go through openings, such bundles get utilized.

Region cluster bundle: Monitoring space and giving greatest execution, is a sort of bundle. For interconnection, it utilizes any excess region of the outer layer of the chip.

Pin-matrix cluster: It is utilized in socketing.

Quad level pack: However it has a lead outline, It is a leadless bundle type.

Chip scale bundle: It is a solitary bite the dust bundle that can be mounted on a superficial level straightforwardly. It contains a little region.

Multichip bundle: It is otherwise called multichip modules. The bundle coordinates numerous ICs, semiconductor passes on, and discrete parts onto a substrate. Thusly, such a game plan looks like a greater IC and makes it a multichip bundle.

Quad level no-lead: basically utilized for surface mounting and near looking like a chip size, it is a small bundle.

Like the BGA one, you ought to take note of that most organizations utilize the region cluster bundles. Because of the requirement for multichip structures, it emerges. To arrangements using the framework on-chip design, such modules and bundles present driving choices. Subsequently, it assists with thinking about every one of these prior to reaching us if you have any desire to get yourself an optimal IC with the right bundling and substrate.

Notwithstanding, a-list client care administrations are presented by this. On the off chance that you can't sort out the best bundling or substrate type for your coordinated circuit, you will get properly directed.

IC Substrates PCB Applications

To explicit electronic items, IC substrate PCB principally applies. With cutting edge capabilities, such items need to demonstrate dainty and lightweight. In this way, on tablet computers, cell phones, organizations, and PCs fundamentally in the military, media transmission, clinical consideration, modern control, and aviation, you will track down IC substrate PCB. However miniature drove is one of the IC substrate applications too, you will find it as a smaller than usual drove PCB In many occasions.

Going from customary HDI printed circuit sheets, coordinated circuit substrate PCB, substrate-like PCBs, or multi-facet PCB, most unbending printed circuit sheets have changed through different advancements.

An IC Substrates Highlights

Lining up with the elements of a coordinated circuit, An IC substrate needs to have explicit qualities. To choose the best IC substrates while planning their ICs, Electronic originators and specialists need to grasp the characteristics of an incorporated circuit. These are a couple of critical IC elements:

Energy-effective: As they consume less power or energy, get at lower costs, and are of more modest volumes, Incorporated circuits are likewise proficient energy.

Cost-viability: When contrasted with their discrete parts, all incorporated circuits frequently show better execution combined with low expenses generally.

Little circuit: The investigating, establishment and configuration processes need to demonstrate basic and uniform as a coordinated circuit is scaled down for the most part.

Lower disappointment: When contrasted with customary circuits, Coordinated circuits have a lesser disappointment rate.

Dependability: Like a ton of work has upgraded their unwavering quality throughout the long term, Coordinated circuits come exceptionally solid particularly in their consistency and execution. In coordinated circuits, Fastening joints get essentially decreased. Making the IC extra dependable, the requirement for virtual welding is likewise diminished moreover.

As probably the most imperative advantages of incorporated circuits, such properties likewise bend over. In any case, it isn't the need here. Particularly while planning the IC of your electronic item, Thought ought to likewise get put on the IC substrate attributes.

IC Substrate Ascribes

IC Substrates have various and different elements. It incorporates the accompanying.

• Less welded joints and lead wires

• Light when the weight is concerned

• At the point when different qualities like weight, sturdiness, and dependability are consistent, improved execution is advertised

• Exceptionally dependable

• Little size