Expand Your Extent of Knowledge about the IC Substrate

Keywords: IC Substrates

Integrated circuit substrates or IC Substrates, in recent times, have shot to prominence. From the emergence of integrated circuit types such as ball grid package and chip-scale package, it has resulted. Something that gets accounted for by IC substrate, such as IC packages call for novel package carriers. To understand the importance of IC package substrate, it no longer proves sufficient as an electronics engineer or designer. You have to comprehend the IC substrate application areas, the role substrate ICs play in the proper functioning of electronics, and its manufacturing process.

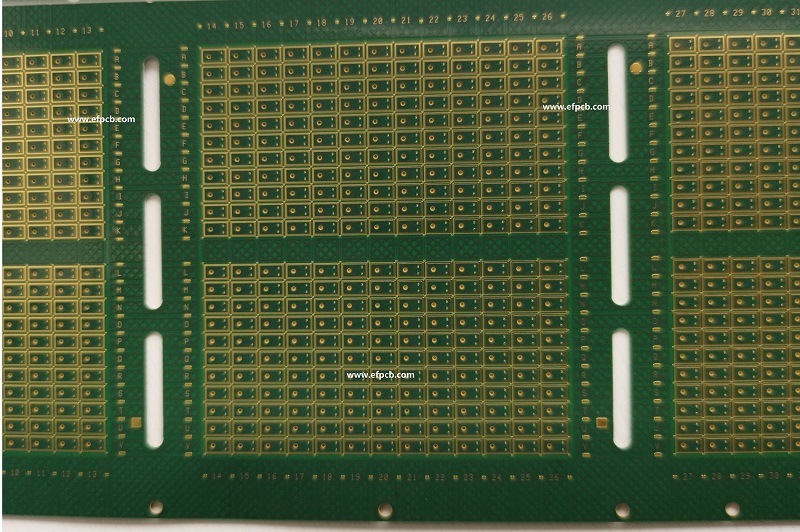

IC Substrate

Utilized in the packaging of bare integrated circuit chips, IC substrate is a baseboard type. In connecting the circuit board and the chip, the substrate IC proves important. Under a transitional product serving to capture semiconductor integrated circuit chip, Integrated circuits fall routing to link the chip with the PCB. Giving it a thermal dissipation tunnel, it also reinforces, supports, and safeguards the IC chip.

The vital role of connectors of the printed circuit boards to the semiconductor chip is played by the Integrated circuit substrate. To provide interconnect densities, It requires capacity on IC fabricators and hence, acts as the conduit. During the IC substrate manufacturing process, this surpasses those of PCB fabricators. In chemical expertise, manufacturers will consequently need solutions regarding high-density designs and a possessing proven specialty. Integrated circuit substrates fall under different classifications and are diverse.

Material that contains the semiconductor device is referred to as IC packaging. Besides allowing for mounting of electrical contacts, it protects it against corrosion or physical damage as a package is encasing the IC substrate. In connecting the electrical contacts to the PCB, It is especially vital. Diverse integrated circuits packaging systems design types exist. As each possesses distinctive needs in the matter of their outer shell, Considerations for these varied types become essential.

IC Packaging

In semiconductor devices production, it often comes as the last step. Protecting the integrated circuit from age-related corrosion or detrimental external elements, the semiconductor receives a casing at this stage. Besides promoting electrical contacts, the casing by design protects the block. To an electronic device’s circuit board, this delivers signals.

When they became popular among EPMs, the IC packaging tech evolved from the BGA packages of the 1970s. However, fresher options and versions overshadowed pin grid array packages from the onset of the 21st century. The plastic quad flat pack and small thin outline packages are included in such technologies. Like the FCBGA, more advanced packaging technologies currently exist. This is an up-gradation of the packages of the land grid array.

Designs of IC Substrates packaging

Based on formation, IC packaging designs also have many categorizations. It includes the lead-frame type and substrate type. Other secondary categorization forms exist while the two form the primary categorization of IC packaging designs. You will find the following here.

Lead-frame and Dual-inline packages: For assemblies that require pins to go through holes, such packages get used.

Area array package: Conserving space and providing maximum performance, is a type of package. For interconnection, it uses any remaining area of the surface of the chip.

Pin-grid array: It is used in socketing.

Quad flat pack: Though it has a lead frame, It is a leadless package type.

Chip scale package: It is a single-die package that can be mounted on the surface directly. It contains a small area.

Multichip package: It is also known as multichip modules. The package integrates multiple ICs, semiconductor dies, and discrete components onto a substrate. Consequently, such an arrangement resembles a bigger IC and makes it a multichip package.

Quad flat no-lead: primarily used for surface mounting and close to resembling a chip size, it is a tiny package.

Like the BGA one, you should note that most companies use the area array packages. Due to the need for multichip structures, it arises. To solutions utilizing the system-on-chip format, such modules and packages present leading options. Therefore, it helps to consider all these before contacting us if you want to get yourself an ideal IC with the correct packaging and substrate.

However, world-class customer care services are offered by this. If you cannot figure out the best packaging or substrate type for your integrated circuit, you will get appropriately guided.

IC Substrates PCB Applications

To specific electronic products, IC substrate PCB mainly applies. With advanced functions, such products have to prove thin and lightweight. Therefore, on tablet PCs, smartphones, networks, and laptops primarily in the military, telecommunication, medical care, industrial control, and aerospace, you will find IC substrate PCB. Though micro led is one of the IC substrate applications as well, you will find it as a mini-led PCB In most instances.

Ranging from traditional HDI printed circuit boards, integrated circuit substrate PCB, substrate-like PCBs, or multilayer PCB, most rigid printed circuit boards have transformed through multiple innovations.

An IC Substrates Features

Aligning with the features of an integrated circuit, An IC substrate needs to have specific characteristics. To select the best IC substrates when designing their ICs, Electronic designers and engineers have to understand the attributes of an integrated circuit. These are a few crucial IC features:

Energy-efficient: As they consume less power or energy, fetch at lower prices, and are of smaller volumes, Integrated circuits are also efficient energy.

Cost-effectiveness: As compared to their discrete components, all integrated circuits often exhibit higher performance coupled with low costs relatively.

Small circuit: The debugging, installation and design processes need to prove simple and uniform as an integrated circuit is miniaturized usually.

Lower failure: As compared to ordinary circuits, Integrated circuits possess a lesser failure rate.

Reliability: Like a lot of work has enhanced their reliability over the years, Integrated circuits come highly reliable especially in their consistency and performance. In integrated circuits, soldering joints get significantly reduced. Making the IC extra reliable, the need for virtual welding is also reduced additionally.

As some of the most vital benefits of integrated circuits, such attributes also double up. However, it is not the need here. Especially when designing the IC of your electronic product, Consideration should also get placed on the IC substrate characteristics.

IC Substrates have numerous and diverse features. It includes the following.

- Fewer soldered joints and lead wires

- Light when the weight is concerned

- When other characteristics like weight, durability, and reliability are constant, Enhanced performance is offered

- Highly reliable

- Small size