Everything You Must Know About Quick Turn PCB

Keywords: Quick Turn PCB, Quick Turn PCB Manufacturer

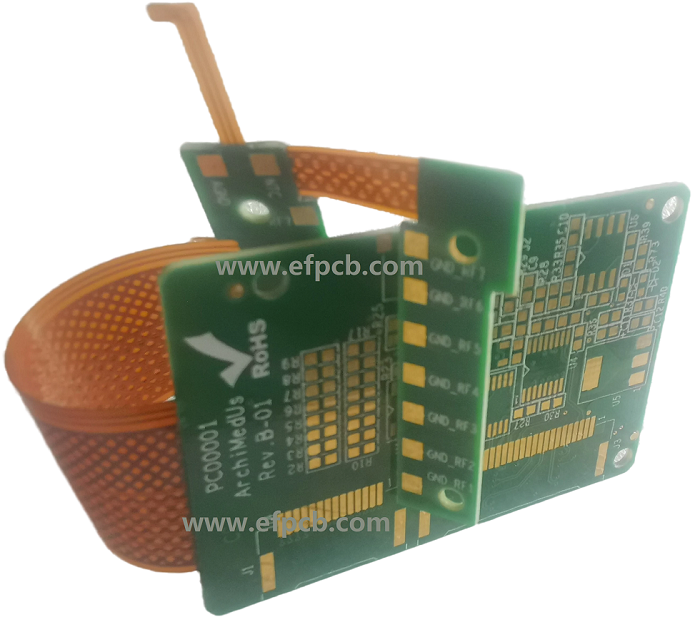

The Quick Turn PCB, a printed circuit board, or PCB, is a circuit board that is designed, made, and put together quickly. With the assurance of high-quality goods and a quick turnaround, it is guaranteed that deadlines and timetables are fulfilled, even for orders with a high volume. In this article, the idea of quick turn in PCB manufacturing is explained, along with the steps, advantages, and phases.

Introduction

Quick-turn PCBs have printed circuit boards (PCBs) that are manufactured and assembled quickly; electronics firms employ this process because it guarantees high-quality end products as well as cost- and time-effectiveness. The expanding market for electrical goods and appliances creates a fiercely competitive environment that calls for large-scale manufacture. Manufacturers can maintain their competitive edge in both quantity and quality because of a too quick turn.

What does Quick Turn mean in the manufacture of PCBs?

A form of PCB fabrication known as "quick turn" enables manufacturers to complete projects or fill orders more quickly than normal without sacrificing quality. The entire PCB fabrication and assembly process may be completed in a relatively short amount of time thanks to a quick turn.

However, quick turn PCB from Quick Turn PCB Manufacturer greatly reduces the production time needed for standard end-to-end PCB assembly, making it much simpler for interested parties to fulfill strict deadlines and constrained timetables.

Sending the PCB design to the manufacturer in a Gerber file format is a step in the quick-turn production process. The de facto standard file format for PCB data transfer from the designer to the manufacturer is the Gerber format. It is now able to safely and successfully exchange entire PCB data, including information on the Board and Assembly.

Therefore, the fabrication business performs a Design for Manufacturability (DFM) assessment on the Quick Turn PCB design after it has been transferred to the manufacturer and checks the material and technical parameters by design criteria and IPC standards. The firm sends out a PCB estimate when the order and file have been authorized, and production and assembly then start.

Early in the fabrication process, prototypes are created to evaluate the product's functionality. Next, pre-production batches are created for additional accuracy checks, and ultimately, high-volume full production is completed as quickly as feasible.