Everything to know About IC Substrate PCB

Keywords: IC Substrates, IC Substrate PCB

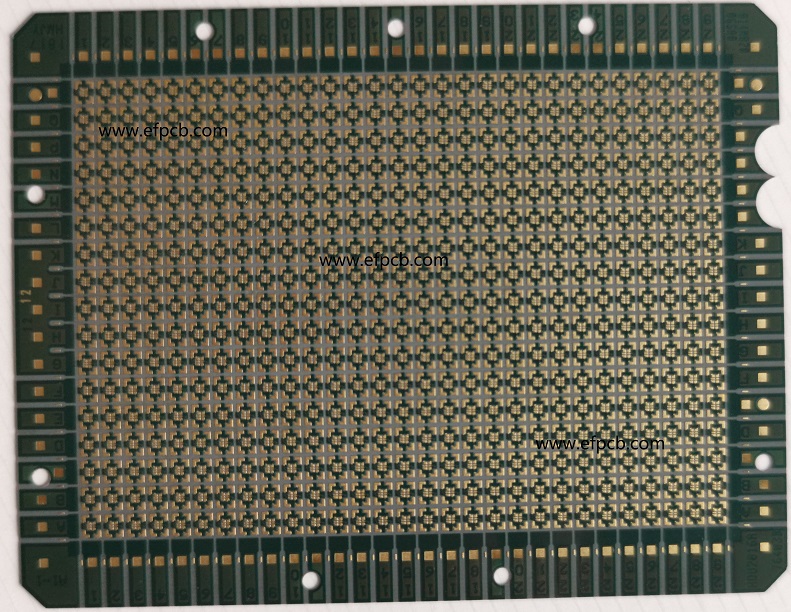

In both popularity and applications, IC substrates PCB has exploded, and that too with any layer HDI PCB and flex-rigid PCB. In telecommunications and electronics updates it is now widely applied.

IC Substrate

IC substrate is a type of baseboard that is utilized in packing bare IC chips. It connects chip and circuit board and with the following functions IC belongs to an intermediate product:

• Semiconductor IC chip is captured by it;

• To connect chip and PCB there’s routing present inside;

• It protects, provides reinforcement, and supports IC chips.

Classifications of IC Substrate

a. It is classified by package types

• BGA IC Substrate. In thermal dissipation and electrical performance, this kind of IC Substrate performs well and can dramatically increase chip pins. So for IC packages with a pin count of over 300 it is quite suitable.

• MCM IC Substrate. MCM is a compact form of a multi-chip module. This type of IC substrate usually absorbs chips with different functions that to in one package. As a result, due to its attributes including shortness, lightness, thinness, and miniaturization the product can be an optimal solution.

• CSP IC Substrate. CSP is a type of single-chip package which is light in weight and has a miniaturized scale, which is quite similar in size to IC Substrate PCB. In memory products, telecommunication products, and electronic products CSP IC substrate is mainly used that too with a small number of pins.

• FC IC Substrate. FC (Flip Chip) is a type of package by flipping chip that features well-performed performance, low circuit loss, low signal interference, and effective thermal dissipation.

b. Classified by material attribute

• Flex IC Substrate. It is made up of PI or PE resin and it features CTE 13 to 27ppm/°C

• Ceramic IC Substrate. By ceramic materials such as Aluminium oxide, Aluminium nitride, or silicon carbide it is primarily made. It features a relatively low CTE.

• Rigid IC Substrates. It is made of epoxy resin, BT resin, or ABF resin. Its CTE is somewhere about 13 to 17ppm/°C.

c. Classified by bonding technology

• FC Bonding

• TAB (Tape Automated Bonding)

• Wire Bonding