Ensuring Reliability and Efficiency with PCB Assembly Design Guidelines

Keywords: PCB Assembly China

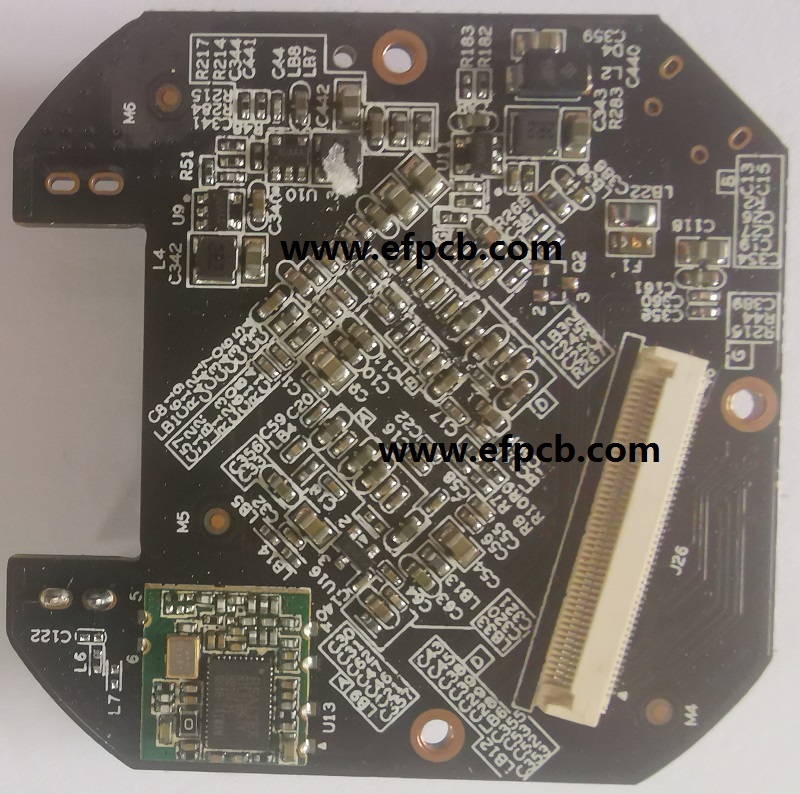

The quality of PCB design greatly influences the efficiency of the assembly process and the reliability of the end product. Whether you're a seasoned engineer or a novice designer, understanding and implementing proper PCB design guidelines for assembly is essential to ensure a smooth manufacturing process and a robust final product. In this blog, we'll delve into the key principles and best practices that can pave the way to successful PCB Assembly China.

- Component Placement and Orientation

The first step in creating an assembly-friendly PCB is thoughtful component placement. Organize components in a way that minimizes the distance between related parts, reduces trace lengths, and optimizes signal paths. Components should also be oriented in a manner that aligns with the pick-and-place machines' capabilities, allowing for seamless automated assembly.

- Keep It Simple

Complexity in PCB design can lead to challenges during assembly. Minimize the number of vias, avoid excessive use of fine-pitch components, and keep the number of layers to a minimum. A simpler design not only speeds up assembly but also enhances the overall reliability of the circuit.

- Design for Manufacturing (DFM)

Consult with your PCB manufacturer early in the design process to ensure your design adheres to its manufacturing capabilities. Factors such as panelization, solder mask layers, and copper thickness should be aligned with the manufacturer's recommendations to prevent costly modifications later on.

- Footprint Accuracy

Accurate component footprints are crucial for proper assembly. Double-check component dimensions, pin spacing, and orientation against datasheets before finalizing footprints. Utilize libraries provided by component manufacturers or trusted industry sources to minimize errors.

- Pad Design and Solder Mask

Ensure that pad sizes are appropriate for the component's lead width or solder ball diameter. Properly designed pads promote strong solder joints and prevent solder bridging. Additionally, use solder mask layers to prevent solder from flowing where it shouldn't during reflow, reducing the likelihood of shorts.

- Thermal Management

Components can generate heat during operation, affecting both performance and reliability. Properly designed thermal vias, heat sinks, and copper pours can help dissipate heat efficiently, preventing overheating and ensuring the longevity of the components.

- Trace Routing

Efficient routing not only enhances signal integrity but also streamlines assembly. Maintain uniform trace widths to ensure consistent soldering during PCB Assembly China. Avoid sharp angles and acute turns, as they can be challenging for pick-and-place machines and may also hinder the flow of solder paste during reflow.

- Keep Components on One Side

While some designs may require components on both sides of the PCB, keeping components on a single side simplifies assembly processes and reduces the chances of errors. If components must be placed on both sides, clearly label the components and reference designators to minimize confusion.

- Avoid Overcrowding

It might be tempting to maximize component density, but overcrowding can lead to difficulties during assembly and potential electrical issues. Provide adequate space between components to accommodate soldering and inspection processes.

- Test Points and Accessibility

Incorporate test points strategically to facilitate testing and debugging. Ensure these points are easily accessible and well-labeled for efficient troubleshooting during assembly and throughout the product's lifecycle.

- Plan for Soldering

Whether using reflow or wave soldering, plan your design to accommodate the chosen soldering method. Ensure that components are properly spaced to prevent solder bridges and that components requiring specific orientation are indicated clearly.

- Anticipate Tolerances

Components and PCBs can have slight variations due to manufacturing tolerances. Design with these tolerances in mind to ensure a proper fit during assembly. Components that fit too tightly can be challenging to place accurately, leading to delays and potential defects.

- Regularly Review Design Rules

Design rules are not set in stone. Regularly review and update them based on feedback from manufacturers, evolving technologies, and industry best practices. Adapting your design rules can help optimize assembly efficiency and overall product quality.

- Prototype and Test

Before proceeding to full-scale production, it's crucial to prototype and thoroughly test your design. This step allows you to identify any assembly challenges, signal integrity issues, or thermal concerns early on, ensuring a smoother transition to large-scale manufacturing.

- Collaboration with Manufacturing Partners

Open lines of communication with your chosen PCB manufacturer are essential. Collaborate with them to ensure your design aligns with their manufacturing capabilities and processes. Their expertise can provide valuable insights to optimize your design for assembly and reliability.

- Design Verification and Simulation

Utilize simulation tools to verify the performance of your design before moving to the manufacturing stage. This includes checking for signal integrity, power distribution, thermal issues, and any potential manufacturing challenges. Addressing these concerns early can prevent costly rework during assembly.

- Component Selection

Carefully select components with a focus on availability and reliability. Opt for components from reputable manufacturers and suppliers, as these components are more likely to have consistent dimensions and characteristics, leading to smoother assembly processes.

- PCB Stackup

The arrangement of layers in a PCB stackup affects signal integrity, impedance control, and overall manufacturability. Work with your manufacturer to determine the optimal stackup configuration for your design to ensure both electrical performance and ease of assembly.

- Ground and Power Planes

A well-defined ground and power distribution network is essential for maintaining signal integrity and reducing noise. Plan and implement ground and power planes strategically to minimize interference and improve the overall stability of your design.

- Design Reviews

Conduct thorough design reviews involving cross-functional teams, including engineers from different disciplines and even representatives from your manufacturing partner. This collaborative approach can uncover potential issues and help you refine your design before entering the assembly phase.

- Material Selection

Choose materials that align with your design's intended use and manufacturing process. Consider factors such as material compatibility, thermal expansion coefficients, and environmental conditions to ensure the reliability and longevity of your product.

- Encapsulation and Protection

Depending on the application, consider the need for protective measures such as conformal coatings, potting, or encapsulation. These measures shield your PCB and components from environmental factors like moisture, dust, and mechanical stress, enhancing overall reliability.

- DFM Software Tools

Leverage Design for Manufacturing (DFM) software tools that can help identify potential assembly issues during the design phase. These tools can offer real-time feedback on component placement, trace routing, and other design elements to optimize manufacturability.

- Stay Abreast of Industry Trends

The field of electronics manufacturing is constantly evolving. Stay up-to-date with the latest industry trends, advancements in assembly technologies, and new materials that can improve the efficiency and reliability of your PCB design.

- Training and Skill Development

Invest in training and skill development for yourself and your design team. Keeping abreast of the latest design tools, assembly techniques, and industry standards can significantly enhance the quality of your designs and their ease of assembly.

- Continual Improvement

The journey towards successful PCB Assembly China doesn't end with one project. Continually refine your design practices, stay curious about new techniques, and be open to adapting your approach based on feedback and emerging technologies.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 IC Substrate Fabricators (2024)

- 10Top 10 Flexible PCB Factories in 2025

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact