Enhancing Efficiency and Innovation: The Role of Electronics Manufacturing Services

Keywords: Electronics Manufacturing Service

Gadgets Assembling Administration (EMS) alludes to a scope of administrations that envelop the plan, assembling, testing, and conveyance of electronic parts, items, and gatherings for unique gear makers (OEMs). EMS suppliers are organizations that offer these administrations, filling in as essential accomplices to OEMs in the hardware business.

EMS suppliers can fluctuate in size and capacities, going from little, specialty firms to huge global partnerships. They take special care of a wide range of ventures, including shopper gadgets, car, medical services, aviation, and modern hardware. The essential objective of EMS is to empower OEMs to rethink the assembling of electronic items, permitting them to zero in on their center capabilities, for example, item configuration, showcasing, and dissemination.

EMS suppliers offer a great many administrations, which can be sorted into the accompanying key regions:

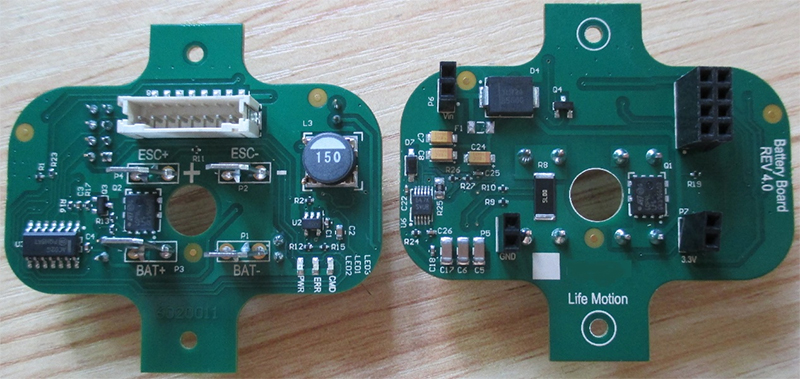

Plan and Designing: EMS organizations frequently give plan and designing administrations, assisting OEMs with streamlining the plan of their electronic items for manufacturability and cost proficiency. This incorporates PCB (Printed Circuit Board) plan, part choice, and the advancement of creation processes.

Prototyping: EMS suppliers make models of electronic items, permitting OEMs to test and refine their plans prior to moving into full-scale creation.

PCB Get together: The gathering of PCBs is a center help given by EMS organizations. This incorporates the position of electronic parts like computer chips, resistors, capacitors, and connectors onto PCBs, trailed by binding and assessment.

Last Get together: EMS suppliers likewise handle the gathering of complete electronic gadgets, incorporating PCBs into lodgings and adding other fundamental parts like presentations, buttons, and connectors.

Testing and Quality Control: Extensive testing and quality control systems are basic to guarantee that electronic items meet their determinations and work dependably. EMS suppliers carry out utilitarian testing, natural testing, and quality checks to distinguish and correct imperfections.

Store network The executives: EMS suppliers deal with the obtainment of parts, materials, and subassemblies expected for creation. They keep up with associations with providers, guaranteeing a consistent stockpile of value parts at cutthroat costs.

Planned operations and Satisfaction: When the items are produced, EMS suppliers can oversee coordinated factors and satisfaction, including bundling, naming, and delivery to conveyance focuses or end clients.

Job of EMS Suppliers in the Gadgets Business

The job of EMS suppliers in the gadgets business is diverse and fundamental. How about we dig into the different parts of their importance:

Cost Proficiency: EMS suppliers are specialists in enhancing the assembling system, decreasing creation costs, and working on generally speaking functional productivity. They influence economies of scale, smoothed out cycles, and inventory network ability to assist OEMs with accomplishing cost reserve funds.

Quicker Time-to-Market: Re-appropriating assembling to EMS suppliers permits OEMs to put up their items for sale to the public all the more quickly. EMS organizations have the foundation and mastery to speed up the creation interaction, empowering faster item dispatches.

Adaptability and Versatility: EMS suppliers offer the adaptability to adjust to changing business sector requests. They can rapidly increase creation volumes or down in light of market changes, guaranteeing that OEMs fulfill client need without overcommitting assets.

Risk Alleviation: Working together with EMS suppliers can moderate dangers related with assembling. EMS organizations are knowledgeable in industry principles, consistence guidelines, and quality control, decreasing the probability of creation issues and item reviews.

Particular Mastery: EMS suppliers have specific information and involvement with hardware fabricating. They stay refreshed on the most recent innovative headways and best works on, permitting OEMs to profit from their mastery.

Admittance to Worldwide Business sectors: Numerous EMS suppliers have a worldwide presence, which empowers OEMs to grow their scope and access new business sectors all the more without any problem. They can fabricate items nearer to target markets, diminishing delivery expenses and travel times.

Asset Advancement: By re-appropriating assembling to EMS suppliers, OEMs can zero in on their center abilities, like innovative work, advertising, and client assistance. This asset assignment upgrades generally business execution.

Quality Confirmation: EMS suppliers are focused on conveying excellent items. They execute thorough quality control cycles to guarantee that items fulfill or surpass industry guidelines, at last upgrading the standing of OEMs.

Cost Consistency: EMS suppliers frequently offer straightforward evaluating models, permitting OEMs to foresee and control their assembling costs all the more really. This consistency is critical for financial plan arranging and monetary soundness.

Natural Obligation: Numerous EMS suppliers focus on manageability and eco-accommodating works on, lessening the natural effect of electronic assembling. This lines up with the developing interest for eco-cognizant items and creation processes.

While Gadgets Assembling Administrations play had a critical impact in the hardware business, they likewise face a few difficulties and are affected by continuous patterns.

Worldwide Production network Interruptions: The Coronavirus pandemic uncovered the weakness of worldwide inventory chains. EMS suppliers are presently rethinking their inventory network techniques, searching for ways of alleviating chances, for example, broadening providers and regionalizing creation.

Industry 4.0 and Robotization: The business is seeing a shift towards Industry 4.0, set apart by expanded computerization and the reception of innovations like the Web of Things (IoT), man-made brainpower (simulated intelligence), and huge information investigation. EMS suppliers are coordinating these advances into their cycles to improve effectiveness, quality, and discernibility.

Scaling down and High level Bundling: Electronic gadgets are turning out to be progressively minimized, and parts are getting more modest. Hardware Assembling Specialist co-ops are putting resources into cutting edge gathering and bundling advances to satisfy these developing needs while keeping up with item trustworthiness.

Green Assembling: Supportability and ecological obligation are acquiring significance. EMS suppliers are executing green assembling rehearses, like diminishing energy utilization, limiting waste, and reusing materials. This lines up with both client requests and administrative prerequisites.

Intricacy in Testing: As electronic gadgets become more refined, testing strategies become more mind boggling. EMS suppliers are creating progressed testing strategies to guarantee the quality and dependability of multifaceted electronic items.

Customization and Personalization: Shoppers are progressively looking for customized electronic items. EMS suppliers are adjusting to take care of this pattern, offering customization choices that permit OEMs to separate their items.

Network protection: With the expansion of associated gadgets, network protection has turned into a vital concern. EMS suppliers are tending to this by executing severe safety efforts in the assembling system and working intimately with OEMs to safeguard delicate information.

Administrative Consistence: The gadgets business is vigorously managed. EMS suppliers should remain refreshed on evolving guidelines, like RoHS (Limitation of Unsafe Substances) and WEEE (Squander Electrical and Electronic Hardware) mandates, to guarantee consistence.

Reshoring: at times, OEMs are reevaluating reshoring, taking assembling back to their nations of origin, to diminish gambles related with long stock chains and international strains. EMS suppliers should be versatile to these evolving elements.

In rundown, Gadgets Assembling Administration assume a significant part in the hardware business by offering a large number of administrations that engage unique gear makers (OEMs) to zero in on their center capabilities while guaranteeing proficient, savvy, and great assembling of electronic items. EMS suppliers are vital accomplices that add to the progress of OEMs and the more extensive hardware biological system, empowering development and mechanical headway in our undeniably electronic-subordinate world.

Electronics Manufacturing Services (EMS) play a crucial role in the modern electronics industry, providing end-to-end solutions for companies seeking to bring their electronic products to market efficiently and cost-effectively. EMS providers offer a wide range of services, including design, prototyping, assembly, testing, and logistics, allowing companies to outsource various stages of the manufacturing process to specialized partners.

One of the key advantages of EMS is its ability to scale production according to demand. Whether it's a small batch of prototypes or a large-scale production run, EMS providers have the capabilities and resources to meet varying production requirements while maintaining consistent quality standards. This scalability enables companies to respond quickly to changes in market demand and optimize inventory levels, reducing excess stock and minimizing carrying costs.

Furthermore, EMS providers offer expertise in supply chain management, sourcing components globally to ensure availability and cost-effectiveness. By leveraging their extensive network of suppliers, EMS providers help reduce lead times and mitigate supply chain risks, enabling companies to focus on core competencies and innovation.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6Top 10 Flexible PCB Factories in 2025

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact