Electronics Manufacturing Service: The Powerhouse behind Innovation

Keywords: Electronics Manufacturing Service

Electronic devices have assimilated into our daily lives in the quickly changing technology landscape of today. Behind the scenes, a powerful force drives the creation and production of these cutting-edge gadgets: Electronics Manufacturing Service (EMS) providers. In this blog, we will delve into the world of EMS and uncover the crucial role they play in bringing innovative ideas to life.

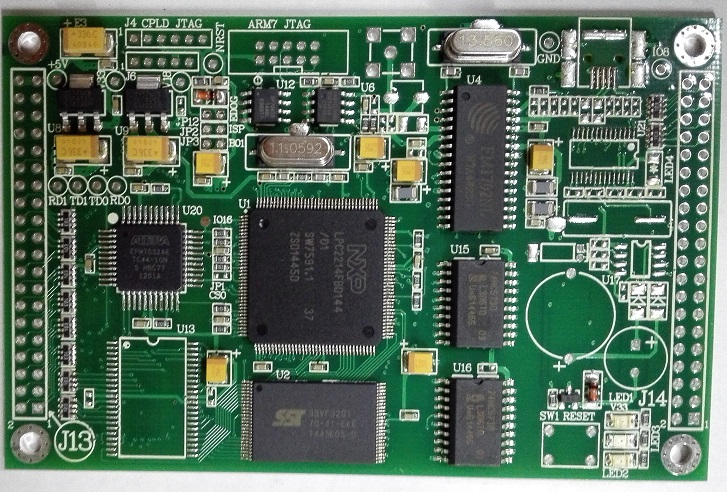

Electronics Manufacturing Service (EMS) refers to the outsourcing of electronic product design, development, and manufacturing to specialized companies. These service providers offer end-to-end solutions, catering to a wide range of industries, including consumer electronics, telecommunications, automotive, healthcare, and more. EMS providers handle various stages of the manufacturing process, such as product prototyping, printed circuit board assembly (PCBA), testing, packaging, and even after-sales support.

The Benefits of Electronics Manufacturing Service

- Expertise and Specialization: EMS providers have extensive knowledge and expertise in electronic design, manufacturing processes, and supply chain management. They invest in advanced technologies, a skilled workforce, and state-of-the-art manufacturing facilities to deliver high-quality products efficiently.

- Cost Savings: Partnering with EMS providers allows companies to avoid hefty upfront investments in manufacturing infrastructure, equipment, and human resources. By leveraging economies of scale, EMS providers can optimize costs and pass on the benefits to their clients.

- Flexibility and Scalability: EMS providers offer flexible manufacturing solutions, enabling companies to adapt quickly to market demands. Whether it's scaling up production volumes during peak periods or introducing product revisions, EMS providers can accommodate these changes efficiently.

- Faster Time-to-Market: With the help of EMS providers, companies can significantly reduce their product development cycles. EMS providers have streamlined processes and access to a vast network of suppliers, enabling faster procurement of components and faster assembly, testing, and shipping of products.

- Quality Assurance: EMS providers have stringent quality control measures in place to ensure that products meet the highest industry standards. They employ rigorous testing methodologies to identify and rectify any manufacturing defects, ensuring that customers receive reliable and high-performing devices.

The EMS Process Explained

- Product Design and Engineering: EMS providers collaborate with clients to understand their requirements and translate them into viable product designs. They conduct feasibility studies, provide design recommendations, and assist in optimizing the product for manufacturability and cost-effectiveness.

- Supply Chain Management: EMS providers leverage their global network of suppliers to source high-quality components at competitive prices. They manage the entire supply chain, from procurement to inventory management, ensuring the timely availability of parts.

- Manufacturing and Assembly: EMS providers possess state-of-the-art manufacturing facilities equipped with advanced equipment and robotics. They follow industry best practices for PCB assembly, surface mount technology, and through-hole assembly, among others. With a focus on efficiency and quality, EMS providers strive for continuous improvement in their manufacturing processes.

- Testing and Quality Assurance: Rigorous testing procedures are employed throughout the manufacturing process to detect any defects or deviations. Functional testing, environmental testing, and reliability testing are conducted to ensure the products meet the specified standards.

- Packaging and Logistics: Once the products are manufactured and tested, EMS providers handle the packaging and shipping process. They ensure that the products are securely packaged, labeled, and delivered to their intended destinations, whether it's a distribution center or directly to end customers.

The Future of EMS

The future of EMS looks promising, with the continued growth of the electronics industry and the increasing complexity of devices. EMS providers are adapting to new technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G connectivity, enabling them to cater to emerging market trends and requirements.

Furthermore, sustainability and environmental considerations are gaining importance in the manufacturing sector. EMS providers are embracing eco-friendly practices, reducing waste, and implementing energy-efficient manufacturing processes to minimize their carbon footprint.

Selecting the Right EMS Provider

Choosing the right Electronics Manufacturing Service provider is crucial for the success of any electronic product. Consider the following factors when evaluating potential EMS partners:

- Experience and Reputation: Look for EMS providers with a proven track record in your industry. Assess their experience, customer testimonials, and case studies to gauge their reliability and capability to deliver.

- Technology and Infrastructure: Ensure that the EMS provider has state-of-the-art facilities, advanced manufacturing equipment, and the ability to handle your specific product requirements. Ask about their investments in emerging technologies and their commitment to staying up-to-date with industry trends.

- Quality Control and Certifications: Quality should be a top priority. Verify if the EMS provider follows strict quality control processes, such as ISO certifications and adherence to industry standards like IPC-A-610 for electronic assembly. Request information on their quality control procedures, testing protocols, and defect rates.

- Supply Chain Management: Evaluate the EMS provider's supply chain management capabilities. Check if they have established relationships with reliable component suppliers and their ability to handle global sourcing and logistics efficiently. A robust and well-managed supply chain ensures timely availability of parts and mitigates risks.

- Communication and Collaboration: Collaboration and clear communication are essential for a fruitful partnership. Assess the EMS provider's responsiveness, accessibility, and willingness to work closely with your team throughout the project. Clear communication channels and regular updates foster a collaborative working relationship.

- Scalability and Flexibility: Consider the EMS provider's ability to scale production volumes and accommodate future growth. Discuss their capacity planning strategies, production capabilities, and their flexibility in accommodating changes or product revisions.

- Cost and Value: Although price is a crucial aspect, it should not be the only one used to decide. Evaluate the EMS provider's pricing structure, cost transparency, and the overall value they bring in terms of expertise, quality, and support.

Conclusion

Electronics Manufacturing Service (EMS) providers are the unsung heroes driving the innovation and mass production of electronic devices. Their expertise, cost-efficiency, and commitment to quality make them indispensable partners for companies seeking to bring their ideas to fruition. As technology continues to advance, the role of EMS providers will become increasingly vital in delivering innovative, high-quality, and sustainable electronics to consumers worldwide.