Electronics Manufacturing Service (EMS): Empowering the Electronics Industry

Keywords: Electronics Manufacturing Service

Electronics Manufacturing Service (EMS) refers to a range of services that encompass the design, manufacturing, testing, and delivery of electronic components, products, and assemblies for original equipment manufacturers (OEMs). EMS providers are companies that offer these services, serving as strategic partners to OEMs in the electronics industry.

EMS providers can vary in size and capabilities, ranging from small, niche firms to large multinational corporations. They cater to a broad spectrum of industries, including consumer electronics, automotive, healthcare, aerospace, and industrial equipment. The primary goal of EMS is to enable OEMs to outsource the manufacturing of electronic products, allowing them to focus on their core competencies, such as product design, marketing, and distribution.

EMS providers offer a wide range of services, which can be categorized into the following key areas:

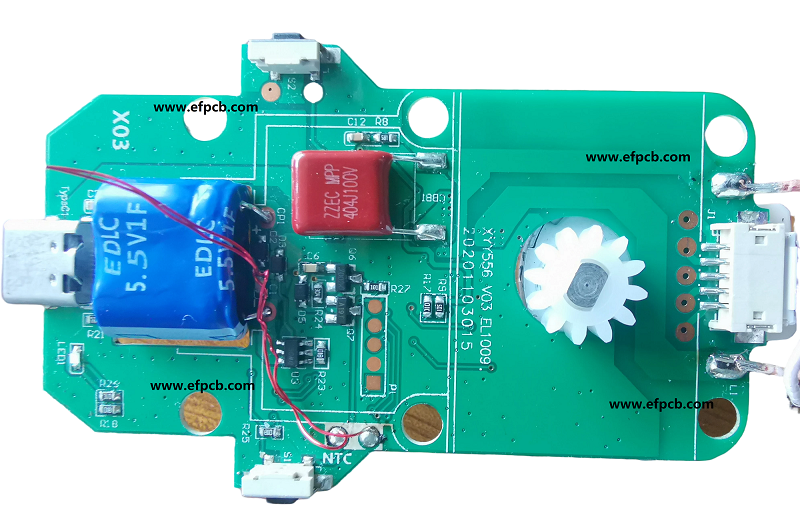

Design and Engineering: EMS companies often provide design and engineering services, helping OEMs optimize the design of their electronic products for manufacturability and cost efficiency. This includes PCB (Printed Circuit Board) design, component selection, and the development of production processes.

Prototyping: EMS providers create prototypes of electronic products, allowing OEMs to test and refine their designs before moving into full-scale production.

PCB Assembly: The assembly of PCBs is a core service provided by EMS companies. This includes the placement of electronic components like microchips, resistors, capacitors, and connectors onto PCBs, followed by soldering and inspection.

Final Assembly: EMS providers also handle the assembly of complete electronic devices, integrating PCBs into housings and adding other necessary components such as displays, buttons, and connectors.

Testing and Quality Control: Comprehensive testing and quality control procedures are critical to ensure that electronic products meet their specifications and operate reliably. EMS providers perform functional testing, environmental testing, and quality checks to identify and rectify defects.

Supply Chain Management: EMS providers manage the procurement of components, materials, and subassemblies required for production. They maintain relationships with suppliers, ensuring a steady supply of quality components at competitive prices.

Logistics and Fulfillment: Once the products are manufactured, EMS providers can manage logistics and fulfillment, including packaging, labeling, and shipping to distribution centers or end customers.

Role of EMS Providers in the Electronics Industry

The role of EMS providers in the electronics industry is multifaceted and essential. Let's delve into the various aspects of their significance:

Cost Efficiency: EMS providers are experts in optimizing the manufacturing process, reducing production costs, and improving overall operational efficiency. They leverage economies of scale, streamlined processes, and supply chain expertise to help OEMs achieve cost savings.

Faster Time-to-Market: Outsourcing manufacturing to EMS providers allows OEMs to bring their products to market more rapidly. EMS companies have the infrastructure and expertise to accelerate the production process, enabling quicker product launches.

Flexibility and Scalability: EMS providers offer the flexibility to adapt to changing market demands. They can quickly scale production volumes up or down based on market fluctuations, ensuring that OEMs meet customer demand without overcommitting resources.

Risk Mitigation: Collaborating with EMS providers can mitigate risks associated with manufacturing. EMS companies are well-versed in industry standards, compliance regulations, and quality control, reducing the likelihood of production issues and product recalls.

Specialized Expertise: EMS providers have specialized knowledge and experience in electronics manufacturing. They stay updated on the latest technological advancements and best practices, allowing OEMs to benefit from their expertise.

Access to Global Markets: Many EMS providers have a global presence, which enables OEMs to expand their reach and access new markets more easily. They can manufacture products closer to target markets, reducing shipping costs and transit times.

Resource Optimization: By outsourcing manufacturing to EMS providers, OEMs can focus on their core competencies, such as research and development, marketing, and customer support. This resource allocation enhances overall business performance.

Quality Assurance: EMS providers are committed to delivering high-quality products. They implement rigorous quality control processes to ensure that products meet or exceed industry standards, ultimately enhancing the reputation of OEMs.

Cost Predictability: EMS providers often offer transparent pricing models, allowing OEMs to predict and control their manufacturing costs more effectively. This predictability is crucial for budget planning and financial stability.

Environmental Responsibility: Many EMS providers prioritize sustainability and eco-friendly practices, reducing the environmental impact of electronic manufacturing. This aligns with the growing demand for eco-conscious products and production processes.

While Electronics Manufacturing Services have played a significant role in the electronics industry, they also face several challenges and are influenced by ongoing trends.

Global Supply Chain Disruptions: The COVID-19 pandemic revealed the vulnerability of global supply chains. EMS providers are now reevaluating their supply chain strategies, looking for ways to mitigate risks, such as diversifying suppliers and regionalizing production.

Industry 4.0 and Automation: The industry is witnessing a shift towards Industry 4.0, marked by increased automation and the adoption of technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. EMS providers are integrating these technologies into their processes to enhance efficiency, quality, and traceability.

Miniaturization and Advanced Packaging: Electronic devices are becoming increasingly compact, and components are getting smaller. Electronics Manufacturing Service providers are investing in advanced assembly and packaging technologies to meet these evolving demands while maintaining product integrity.

Green Manufacturing: Sustainability and environmental responsibility are gaining importance. EMS providers are implementing green manufacturing practices, such as reducing energy consumption, minimizing waste, and recycling materials. This aligns with both customer demands and regulatory requirements.

Complexity in Testing: As electronic devices become more sophisticated, testing procedures become more complex. EMS providers are developing advanced testing methods to ensure the quality and reliability of intricate electronic products.

Customization and Personalization: Consumers are increasingly seeking personalized electronic products. EMS providers are adapting to cater to this trend, offering customization options that allow OEMs to differentiate their products.

Cybersecurity: With the proliferation of connected devices, cybersecurity has become a paramount concern. EMS providers are addressing this by implementing stringent security measures in the manufacturing process and working closely with OEMs to protect sensitive data.

Regulatory Compliance: The electronics industry is heavily regulated. EMS providers must stay updated on changing regulations, such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, to ensure compliance.

Reshoring: In some cases, OEMs are reconsidering reshoring, bringing manufacturing back to their home countries, to reduce risks associated with long supply chains and geopolitical tensions. EMS providers need to be adaptable to these changing dynamics.

In summary, Electronics Manufacturing Service play a pivotal role in the electronics industry by offering a wide range of services that empower original equipment manufacturers (OEMs) to focus on their core competencies while ensuring efficient, cost-effective, and high-quality manufacturing of electronic products. EMS providers are strategic partners that contribute to the success of OEMs and the broader electronics ecosystem, enabling innovation and technological advancement in our increasingly electronic-dependent world.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 Flexible PCB Factories in 2025

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact