Different Types of PCB Inspection Methods

Keywords: PCB Assembly China, Printed Circuits Assembly

The course of If you have any desire to fabricate or build circuit sheets then the interaction is essentially of a two-stage that comprises of creation and gathering. There is the production of an essential uncovered Printed Circuits Assembly structure during testing and reviewing the generally speaking PCBA, manufacture and gathering comprises of joining the parts. The scope of conceivable circuit board test regimens can shift contingent upon the plan and expected utilization of the board and they even approve the nature of the assembling system broadly. PCB assessment techniques are crucial for board fabricate undertakings that are performed for all sheets.

PCB testing tells you in regards to the usage of gear with the goal that you can totally evaluate a physical or electrical property or normal for the circuit board structure. Trademark impedance conclusions twist range and strip pressure are instances of PCB that is estimated with the assistance of a period space reflect meter (TDR).

The significant motivation behind examining sheets is to distinguish the disappointment modes. Be that as it may, you will discover a few advantages. For instance, by doing a reliable review you can foresee the possible disappointments. Over the long run assuming there is debasement in the quality regardless of whether it is inside adequate cutoff points, it shows that some cycle change is required. For PCB yield judgments assessments give precise information. In an ideal plan improvement agenda, this plan approval is a basic part and it ought to utilize both manual and mechanized PCB Assembly China examination strategies.

Various Types of PCB Inspection Method

Manual

Manual board investigation is the visual assessment of a PCBA that is completed with the unaided eye or another optical hardware. The advantage of this sort of examination is that it assists the experts or quality control faculty with focusing on specific region of the board or explicit parts.

Computerized

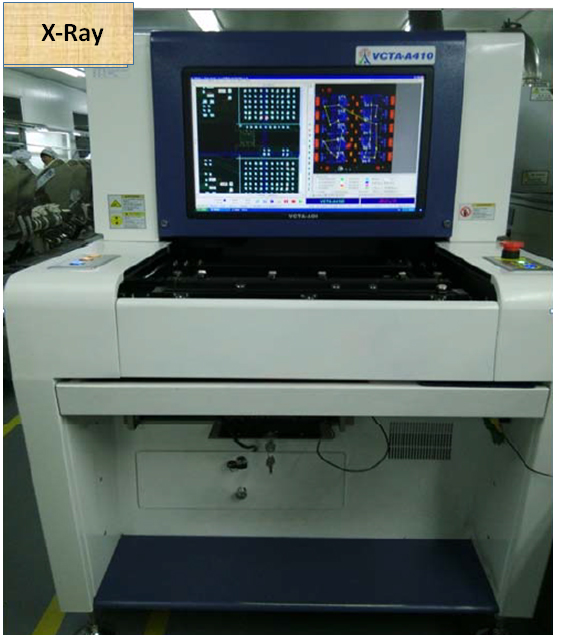

With the assistance of computerizing examination, assembling can accomplish the quick completion times that are expected to arrive at ideal quality during the improvement of the model. In giving significant level pictures of inner availability and vias of the PCBA, the robotized cycle which is alluded to as computerized optical review (AOI), utilizes picture handling and programming.

In Printed Circuits Assembly process review is a fundamental component since it actually takes a look at both quality and approves the degree of value control in the assembling system.