Design, Materials, and Manufacturing Challenges of High Volume PCB

Keywords: High Volume PCB

Printed Circuit Sheets (PCBs) are the foundation of pretty much every electronic gadget we use. They are utilized to associate electronic parts and give an electrical way to signs and power. High Volume PCB is PCBs that are made in huge amounts. They are utilized in various businesses, including shopper gadgets, car, aviation, clinical, and numerous others.

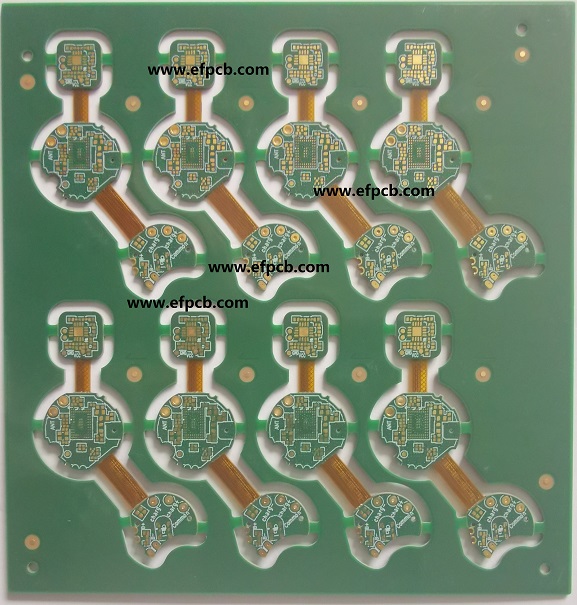

High Volume PCBs are made utilizing various methods and innovations, including surface mount innovation (SMT), through-opening innovation (THT), and crossover innovation. They are additionally created utilizing various kinds of materials, like FR-4, polyimide, and earthenware. In this blog, we will investigate the different parts of High Volume PCBs.

Plan Contemplations for High Volume PCBs

Planning a High Volume PCB requires cautious thought of a few elements, like part situation, signal directing, and warm administration. The objective is to plan a PCB that is solid, proficient, and financially savvy.

One significant thought is part arrangement. Parts should be set in a manner that boosts the utilization of room on the PCB. This is significant on the grounds that more modest PCBs can decrease fabricating costs and work on the general execution of the gadget. It is likewise fundamental for place parts in a manner that limits the length of sign ways. This assists with diminishing the gamble of sign corruption and electromagnetic obstruction (EMI).

Signal steering is another significant thought. Signal ways should be intended to limit commotion and sign misfortune. Rapid signs, specifically, require cautious steering to keep up with signal respectability. The utilization of controlled impedance follows can assist with keeping signal quality over lengthy separations.

Warm administration is likewise a fundamental thought. High Volume PCBs produce a ton of intensity, and it is essential to plan a PCB that can proficiently disseminate intensity to forestall harm to parts. This can be accomplished by utilizing warm vias, heat sinks, and other cooling procedures.

Fabricating Interaction for High Volume PCB

The assembling system for High Volume PCB is a complex and multi-step process that includes a few phases, including plan, manufacture, gathering, and testing.

The initial step is planning. The plan interaction includes making a schematic of the circuit and spreading out the PCB. This is finished utilizing specific programming, like Altium, Hawk, or KiCAD. When the plan is finished, it is moved to an assembling record design, for example, Gerber or ODB++, which is utilized to make the PCB.

The subsequent step is a creation. The manufacture interaction includes making the PCB from the assembling document. This is finished utilizing various procedures, like drawing, boring, and plating. The objective is to make a PCB that matches the plan details.

The third step is gathering. The gathering system includes joining parts to the PCB. This is finished utilizing robotized get together gear, for example, pick-and-spot machines. Parts are joined utilizing surface mount innovation (SMT) or through-opening innovation (THT), contingent upon the plan particulars.

The last step is trying. The testing system includes checking that the PCB meets the plan particulars. This is finished utilizing different methods, like visual examination, robotized optical investigation (AOI), and utilitarian testing.

Material Choice for High Volume PCBs

The choice of materials for High Volume PCBs is basic to the exhibition and dependability of the gadget. There are a few variables to consider while choosing materials, like expense, execution, and manufacturability.

FR-4 is the most well-known material utilized for High Volume PCBs. It is a minimal expense, flexible material that is not difficult to work with and gives great electrical and mechanical properties. Be that as it may, FR-4 isn't reasonable for high-temperature applications or high-recurrence circuits.

For high-temperature applications, polyimide is a well known decision. Polyimide has a high-temperature resistance and can endure temperatures of up to 250°C. It is additionally lightweight, adaptable, and has great substance opposition. Polyimide is regularly utilized in aviation, car, and clinical applications.

Clay is another material that is reasonable for High Volume PCBs. Earthenware gives superb warm conductivity and can deal with high frequencies. It is normally utilized in high-recurrence applications, like cell base stations, satellite correspondences, and radar frameworks. Nonetheless, clay is a more costly material contrasted with FR-4 or polyimide.

Aside from the base material, the decision of copper thickness likewise assumes a critical part in the exhibition and unwavering quality of High Volume PCBs. The most well-known thicknesses are 1oz and 2oz, with thicker copper giving better conductivity and intensity dispersal.

Challenges in High Volume PCB Assembling

High Volume PCB producing is a mind boggling and testing process that requires huge interest in hardware, innovation, and gifted work. One of the fundamental difficulties is guaranteeing reliable quality across an enormous volume of PCBs. Indeed, even little varieties in the assembling system can bring about massive contrasts in execution and dependability.

Another test is overseeing lead times and completion times. High Volume PCBs are frequently expected for large scale manufacturing, and any defers in assembling can altogether affect creation timetables and productivity.

At last, overseeing cost is a basic test in High Volume PCB producing. The expense of materials, hardware, and gifted work can rapidly add up, and producers should track down ways of offsetting cost with execution and unwavering quality.

Moreover, the pattern towards scaling down and more prominent usefulness of electronic gadgets likewise presents a test in High Volume PCB producing. More modest structure factors and higher part densities require accuracy in plan and assembling processes. This requires more noteworthy tender loving care, quality control, and concentrated gear.

One area of development that is assisting with tending to these difficulties is the utilization of robotization in High Volume PCB producing. Computerization can assist with expanding proficiency, diminish costs, and further develop consistency and quality. For instance, robotized optical review (AOI) can rapidly recognize and distinguish deserts in PCBs, diminishing the gamble of human mistake and working on quality control.

One more area of development is the utilization of AI and man-made consciousness in High Volume PCB fabricating. These advancements can assist with streamlining creation processes, anticipate disappointments, and distinguish potential open doors for development. They can likewise assist with decreasing waste, increment productivity, and work on in general execution and dependability.

End

High Volume PCBs are basic parts in pretty much every electronic gadget we use. They are utilized in a large number of ventures and require cautious thought in the plan, material choice, and assembling. Steady quality, lead times, and cost administration are fundamental elements in High Volume PCB fabricating.

The continuous advances in innovation, like the web of things (IoT), man-made consciousness (artificial intelligence), and 5G, are driving the interest for additional edifices and higher-performing High Volume PCB. Producers should keep on putting resources into hardware, innovation, and gifted work to stay aware of the rising interest and keep up with their seriousness in the worldwide market.