Design Considerations for Rigid Flex PCBs

Keywords: Flex Circuits Board, Rigid Flex PCB, Rigid Flexible PCB Manufacturer

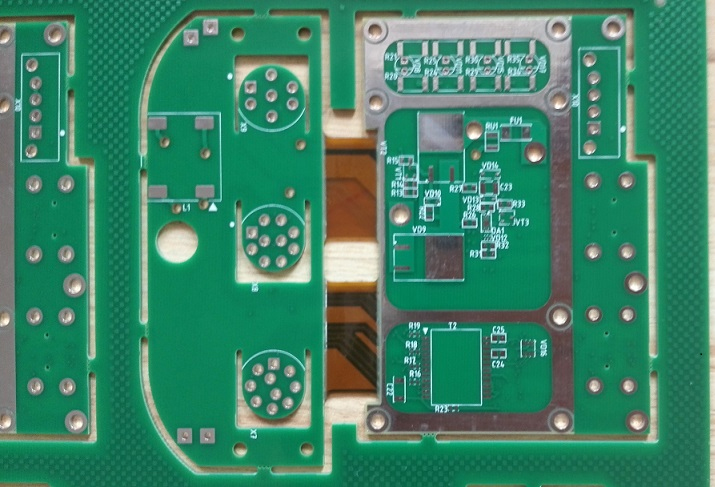

A Rigid Flex PCB is a type of PCB that combines rigid and flexible substrates to create a single board that is both flexible and rigid. It is made up of multiple layers of flexible and rigid materials that are bonded together, resulting in a board that can bend and twist while still maintaining its shape and structural integrity.

Rigid Flex PCBs are commonly used in applications where the PCB needs to fit into a small or unusual space, or where the PCB needs to be able to withstand repeated bending and twisting. Some common applications for Rigid Flex PCBs include medical devices, aerospace and defense systems, and wearable electronics.

Design Considerations for Rigid Flex PCBs

Designing a Rigid Flex PCB requires a different approach than designing a traditional rigid or flexible PCB. Some key design considerations include:

Material selection: Choosing the right combination of rigid and flexible materials is critical to the success of a Rigid Flex PCB. The materials of the Flex Circuits Board should be compatible with each other and should be able to withstand the thermal and mechanical stresses of the application.

Layer stackup: The layer stackup for a Rigid Flex PCB should be carefully designed to ensure that the board is both flexible and rigid where it needs to be. This requires a good understanding of the mechanical properties of the materials being used.

Bend radius: The bend radius of a Rigid Flex PCB is an important consideration, as it can impact the board's reliability and performance. The bend radius should be designed to minimize stress on the board while still allowing it to bend and twist as needed.

Component placement: The placement of components on a Rigid Flex PCB should be carefully considered to ensure that they are in the correct position to take advantage of the board's flexibility and to minimize stress on the components during bending or twisting.

In conclusion, Rigid Flex PCBs from the Rigid Flexible PCB Manufacturer is an innovative and versatile solution for electronic devices that require a combination of flexibility and rigidity. With their space-saving design, increased reliability, and improved signal integrity, Rigid Flex PCBs are a good choice for a wide range of applications, from medical devices to aerospace and defense systems. However, designing a Rigid Flex PCB requires careful consideration of material selection, layer stackup, bend radius, and component placement, making.