Contemplations for Planning a Drove PCB Board

Keywords: LED PCB Manufacturer, LED PCB China

You should consider the materials utilized how to deal with the intensity, follow directing, and the completion while making a Drove printed circuit board or LED PCB China.

A printed circuit board's materials ought to collaborate to deplete overabundance heat, protect conveyors, and empower electrical associations between Drove parts.

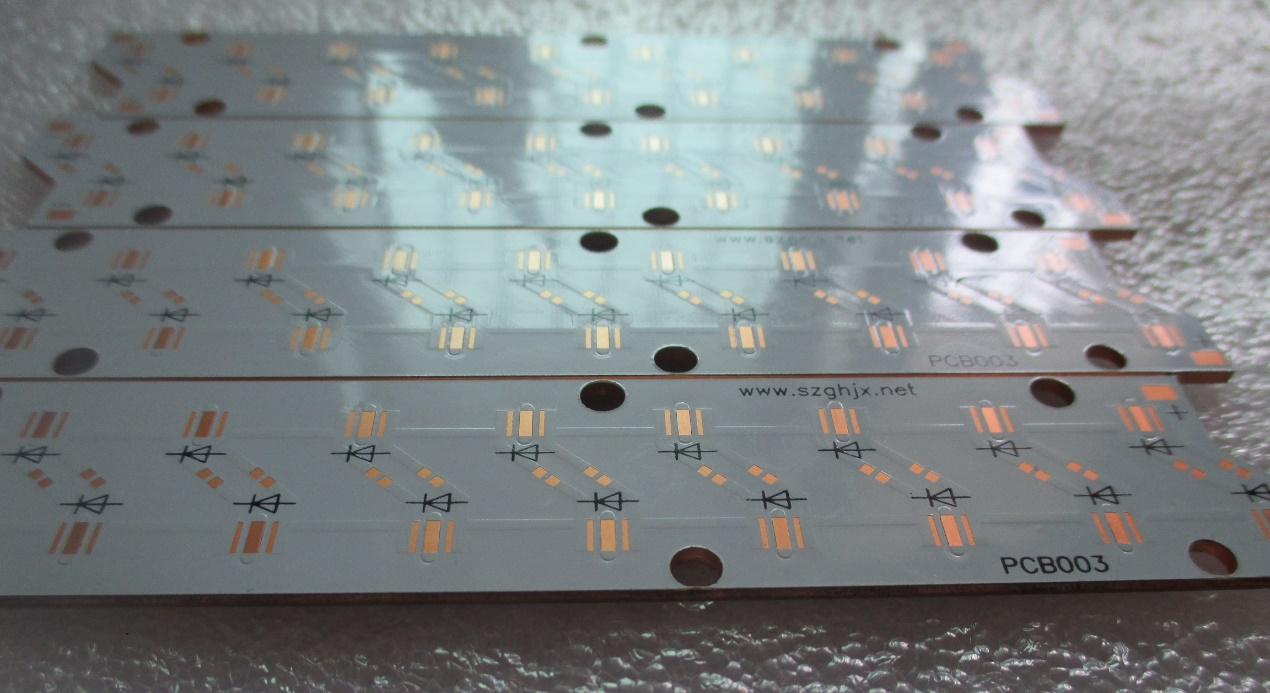

Aluminum is oftentimes utilized as the establishment layer for Drove circuit loads up. The copper circuit layer and the bind cover are put on top of the dielectric layer, which is set over the aluminum base. The term protected metal substrate is one more name for this sort of development (IMS). The aluminum base works effectively of disseminating additional intensity and helping with warm control.

Brilliant administration

One of the most basic parts of Driven plan is warm control. Temperatures that aren't as expected controlled can lessen a gadget's life expectancy and compromise the light's variety virtue. Accordingly, aluminum centers and intensity sinks are as often as possible utilized in Drove circuit board plans to scatter heat from the parts as much as attainable. Plan contemplations ought to incorporate how the parts are organized and where the LEDs are situated since these elements influence how intensity is scattered and taken out from the air.

Course following

Crosstalk between circuits, open and short circuits, and fabricating issues may be generally kept away from with legitimate follow steering plan. By utilizing follow steering, all organization associations are made accurately and without break from different associations. Overheating is tried not to by utilize follows with the right width.

Finish

The board's clean keeps the circuit layer safe and gives the gathering a spot to weld parts. There are a few printed circuit board coatings that each have their advantages and downsides. Discussing the board's assumptions and the task spending plan might assist you with picking the legitimate completion. Standard epoxy glass or metal centers are generally found in Drove printed circuit board centers from Drove PCB Maker.

Iron center

Aluminum is the most average metal center utilized in Drove printed circuit sheets. Heat is promptly moved from the board to the outside by this metal. By doing this, it further develops the intensity sink's capacity to protect the circuit board's parts from being hurt by high intensity.

Since introducing whatever through the board could bring about short circuits in the event that the patch meets the metal inside of the circuit board, such Drove PCB China need surface-mounted parts. Metal centers turn out only great for Drove parts, however, as they are surface mounted.