Construction, Benefits, and Applications of Multilayer PCBs

Keywords: Multilayer PCB

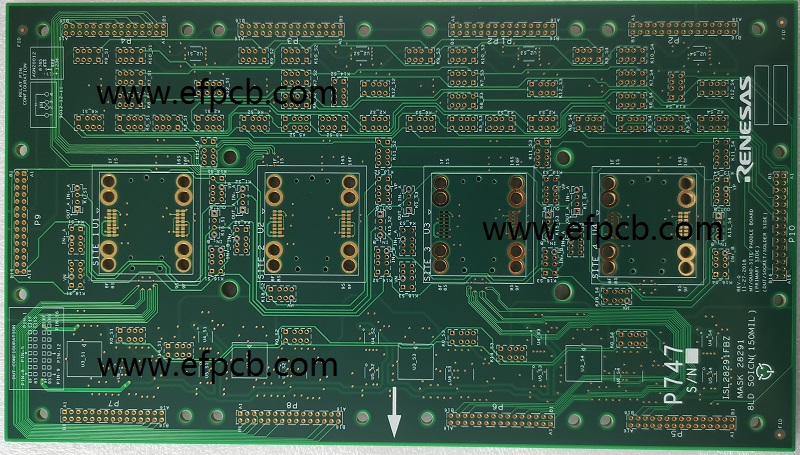

In today's fast-paced world where electronic devices continue to shrink in size while demanding higher performance, Multilayer Printed Circuit Boards (PCBs) have emerged as a game-changer. These intricate circuit boards, comprising multiple layers of copper traces and insulating material, offer significant advantages over their single-layer counterparts. From enhanced functionality and reduced size to improved signal integrity and high-density interconnections, Multilayer PCB is revolutionizing the landscape of modern electronics. In this blog, we will delve into the world of Multilayer PCBs, exploring their construction, benefits, applications, and the role they play in shaping the technological advancements of tomorrow.

Construction and Design for Multilayer PCB

Multilayer PCBs are constructed by sandwiching multiple layers of copper traces between layers of insulating material, typically a resin-based substrate known as the core. Each copper layer is etched to create a specific circuit pattern, allowing for the efficient flow of electrical signals. The layers are then laminated together, forming a compact and robust board structure.

The construction of a Multilayer PCB involves several critical elements, including vias, pads, and through-hole plating. Vias are small plated holes that connect different layers of the board, enabling vertical signal flow and interconnections between traces. Pads act as the contact points for component soldering, facilitating the attachment of electronic components to the PCB. Through-hole plating ensures electrical conductivity between layers by coating the walls of vias with a conductive material.

Benefits of Multilayer PCB

The utilization of Multilayer PCBs brings forth a multitude of benefits and advantages, making them an indispensable component in modern electronics. Let's explore some key advantages:

- High Density and Compactness: Multilayer PCBs allow for an increased density of electronic components due to their multiple layers. This results in more functionality within a smaller form factor, enabling the creation of sleek and compact devices.

- Improved Signal Integrity: The presence of multiple layers in Multilayer PCBs reduces signal interference and cross-talk, enhancing the overall signal integrity. This is especially critical in high-frequency applications where maintaining signal quality is paramount.

- Enhanced Reliability: Multilayer PCBs offer improved reliability due to their reduced susceptibility to electromagnetic interference (EMI) and noise. They provide better thermal management, minimizing the risk of overheating, and reducing the chances of signal degradation and component failure.

- Simplified Routing: With multiple layers at their disposal, designers can efficiently route complex interconnections, reducing signal path length and impedance issues. This leads to improved performance and reduced transmission delays.

Applications

The widespread adoption of Multilayer PCBs has unlocked a plethora of applications across various industries. Here are some notable examples:

- Telecommunications: Multilayer PCBs are extensively used in the telecommunications industry to power the ever-evolving landscape of mobile devices and network infrastructure. From smartphones and tablets to base stations and routers, the compactness and high-performance capabilities of Multilayer PCBs enable seamless connectivity and efficient data transfer.

- Automotive Electronics: The automotive sector heavily relies on Multilayer PCBs for its advanced electronic systems. These PCBs enable the integration of various modules, such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The compact nature of Multilayer PCBs is especially crucial in vehicles where space optimization is vital.

- Medical Devices: The medical field benefits greatly from Multilayer PCB in the development of cutting-edge medical devices. From pacemakers and defibrillators to MRI machines and monitoring equipment, Multilayer PCBs provide the necessary high-density interconnections, signal integrity, and reliability required for critical healthcare applications.

- Aerospace and Defense: Multilayer PCBs play a vital role in aerospace and defense applications. They enable the construction of lightweight yet robust electronic systems for satellites, avionics, and military equipment. The high reliability and signal integrity of Multilayer PCBs are crucial for mission-critical operations.

Future Developments and Challenges

As technology continues to advance, the development of Multilayer PCBs is expected to follow suit. Here are some potential future developments and challenges in the field:

- Miniaturization: The demand for smaller, more powerful electronic devices will drive the need for even more compact Multilayer PCBs. Researchers and engineers are exploring new materials and manufacturing techniques to achieve higher densities and reduce the size of PCBs while maintaining signal integrity.

- Flexible and Rigid-Flex PCBs: Flexibility in electronic devices is becoming increasingly important, leading to the rise of flexible and rigid-flex PCBs. These PCBs combine flexible and rigid sections, enabling the creation of bendable and foldable devices. Future developments in Multilayer PCBs will focus on enhancing the flexibility and durability of these boards.

- High-Frequency Applications: With the growing demand for high-frequency applications such as 5G communications and IoT devices, Multilayer PCBs will need to support faster signal propagation and minimize signal loss. Advanced materials and improved design techniques will be crucial in meeting these challenges.

- Thermal Management: As electronic devices become more powerful, heat dissipation becomes a critical factor. Future Multilayer PCBs will incorporate innovative thermal management techniques such as embedded heat sinks, advanced materials with high thermal conductivity, and efficient airflow designs to ensure optimal performance and reliability.

- Challenges in the development of Multilayer PCBs include cost optimization, efficient manufacturing processes, and ensuring high yields during production. The complexity of Multilayer PCB design and manufacturing requires skilled engineers and specialized equipment, which can increase production costs. However, ongoing research and advancements in manufacturing technologies are addressing these challenges and making Multilayer PCBs more accessible and cost-effective.

The Impact on Sustainability and Environmental Considerations

While Multilayer PCBs offer numerous advantages in terms of functionality and performance, it is crucial to consider their impact on sustainability and environmental factors. The manufacturing and disposal of PCBs can have adverse effects on the environment if not properly managed.

One of the key environmental concerns associated with Multilayer PCBs is the use of hazardous materials during their production. PCB manufacturing involves the use of chemicals, such as solvents and acids, which can pose risks to human health and the environment if not handled properly. It is essential for manufacturers to adhere to stringent regulations and adopt environmentally friendly practices to minimize the negative impact of these chemicals.

Additionally, the disposal of PCBs presents a challenge. Improper disposal methods can lead to the release of harmful substances into the environment, including heavy metals and toxic chemicals. Proper recycling and disposal processes, such as through authorized recycling facilities, are essential to mitigate these risks.

To address these environmental concerns, efforts are being made to develop more sustainable practices in the PCB industry. This includes the use of alternative materials that are less harmful to the environment, implementing more efficient manufacturing processes to reduce waste, and promoting responsible recycling and disposal practices.

Furthermore, designing Multilayer PCBs with longevity in mind can contribute to sustainability. By creating robust and durable PCBs, the need for frequent replacements and disposal is reduced, resulting in a more sustainable lifecycle for electronic devices.

Conclusion

As we dive deeper into the era of miniaturization and heightened performance, Multilayer PCB has emerged as a foundational element of modern electronics. Their ability to house complex circuitry, optimize space, and maintain signal integrity makes them indispensable in numerous industries. From telecommunications to automotive, medical devices to aerospace, Multilayer PCBs continue to drive technological advancements and pave the way for innovation. With ongoing research and development, we can expect Multilayer PCBs to further evolve, enabling even more compact, powerful, and reliable electronic systems that will shape the future of our interconnected world.