Choosing the Right PCB Manufacturer on the Basis of Quality, Lead Times, and Cost

Keywords: Printed Circuit Board Manufacturer

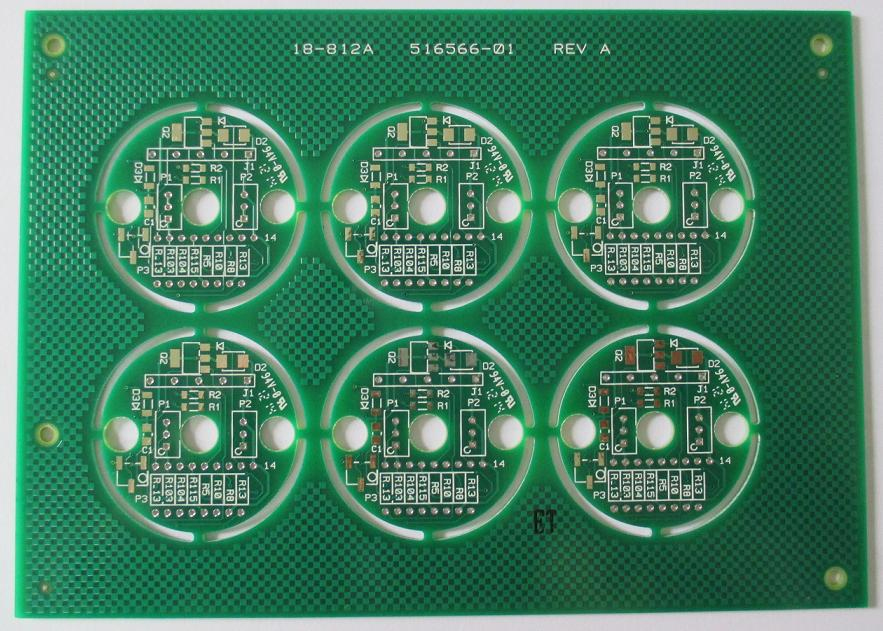

Printed Circuit Boards (PCBs) are the backbone of electronic devices, serving as the essential platform for connecting and powering various components. When it comes to bringing your electronic designs to life, selecting the right Printed Circuit Board Manufacturer is a critical decision that can significantly impact your project's success. In this blog post, we'll explore key factors to consider – cost, lead times, and quality – to guide you in making an informed choice.

Printed Circuit Board Cost Considerations

Upfront Costs

When assessing the cost aspect, it's essential to look beyond the initial quote. Consider factors such as setup fees, tooling costs, and any additional charges that may be incurred during the manufacturing process.

Volume Pricing

Printed Circuit Board Manufacturer often offer volume discounts. Evaluate your production needs and choose a manufacturer that provides favorable pricing structures for the quantities you anticipate.

Material Costs

Inquire about the quality of materials used and ensure they align with your project requirements. While it may be tempting to opt for the lowest cost, compromising on material quality can lead to long-term issues.

Lead Times

Production Time

Time-to-market is crucial in the electronics industry. Evaluate the manufacturer's production capabilities and inquire about their standard lead times. Some manufacturers may offer expedited services at an additional cost.

Prototyping Services

If prototyping is a significant part of your development process, check if the manufacturer provides quick-turn PCB services. This can be crucial for refining your design before mass production.

Communication and Transparency

Choose a manufacturer that communicates clearly about their production schedule and potential delays. A transparent and responsive manufacturer can help you plan your project timeline more effectively.

Quality Assurance

Certifications

Ensure that the PCB manufacturer holds relevant certifications, such as ISO 9001, to guarantee adherence to quality standards. Certifications indicate a commitment to maintaining consistent quality in their processes.

Testing Procedures

Inquire about the manufacturer's testing procedures. Rigorous testing, including electrical testing and functional testing, helps identify and rectify any defects before the final product is shipped.

Supplier Relationships

Assess the relationships of the Printed Circuit Board Manufacturer with their material suppliers. A manufacturer that collaborates with reputable suppliers is more likely to source high-quality components for your PCBs.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact