Keywords: PCB Manufacturing

The COVID-19 pandemic has had a profound impact on nearly every industry, and the world of PCB (Printed Circuit Board) manufacturing is no exception. As the world grappled with lockdowns, supply chain disruptions, and shifts in consumer behavior, the PCB manufacturing sector faced its own set of unique challenges. However, with adversity comes innovation, and the PCB industry has adapted to the changing landscape. In this blog, we'll explore the evolving landscape of PCB manufacturing in a post-pandemic world, the challenges it faced, and the innovations that are reshaping the industry.

Supply Chain Disruptions

The pandemic exposed vulnerabilities in global supply chains. PCB manufacturers heavily rely on a steady supply of raw materials, components, and specialized equipment. Lockdowns, transportation disruptions, and workforce shortages led to delays and increased costs.

Workforce Issues

Social distancing measures and lockdowns limited the number of workers that could be present on the factory floor at a given time. This not only impacted production efficiency but also increased labor costs.

Uncertainty in Demand

Consumer demand for electronics fluctuated during the pandemic. PCB manufacturers had to manage their production levels and inventory in an unpredictable environment, leading to potential revenue losses or overstocked warehouses.

Technological Advancements

Technological advancements in PCB Design and PCB manufacturing continued during the pandemic. Manufacturers had to adapt to new design specifications and fabrication techniques to remain competitive.

Automation and Robotics

To address labor shortages and social distancing requirements, PCB manufacturers have turned to automation and robotics. These technologies help improve production efficiency, reduce labor costs, and maintain production continuity during lockdowns or labor shortages.

Resilient Supply Chains

Many manufacturers are now reevaluating and diversifying their supply chains. This includes building relationships with local suppliers and exploring alternative sources for critical components and materials to reduce the risk of future disruptions.

Advanced Materials and Processes

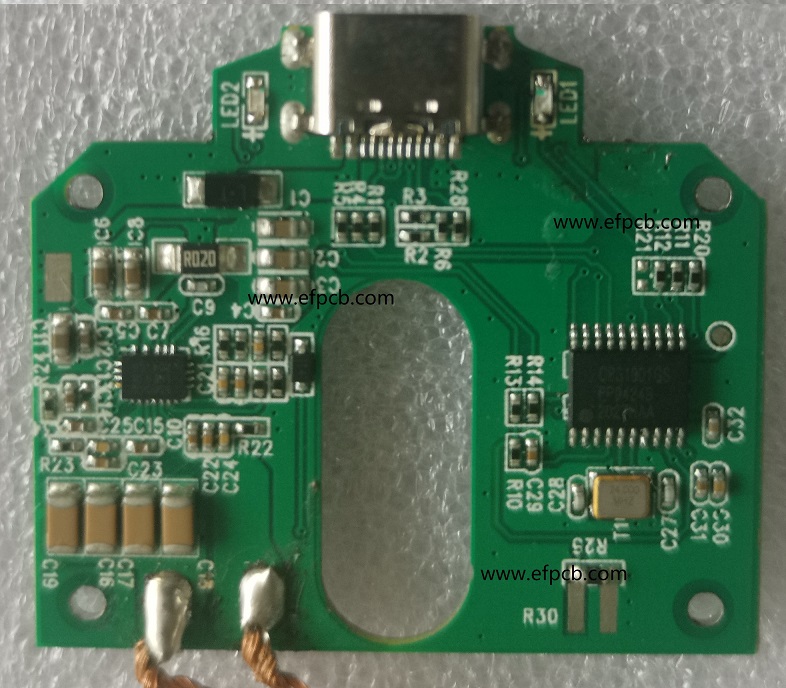

PCBs are becoming more complex and compact. Manufacturers are investing in advanced materials, such as flexible substrates and high-frequency laminates, to meet the demands of 5G, IoT, and automotive applications.

Reskilling and Workforce Management

To address workforce challenges, PCB manufacturers for PCB manufacturing are focusing on reskilling and upskilling employees. Cross-training and versatile skillsets enable workers to adapt to changing production needs.