Certifications and Regulatory Requirements for Gold Finger PCBs

Keywords: Gold Finger PCB Manufacturer

In the intricate world of electronics, Printed Circuit Boards (PCBs) are the unsung heroes, enabling the seamless operation of a wide range of devices. Gold Finger PCBs, in particular, play a crucial role in industries that demand uncompromising quality and reliability. These industries, often with stringent standards, require Gold Finger PCBs to adhere to specific regulatory requirements and certifications to ensure optimal performance and safety. In this blog, we'll delve into the world of regulatory requirements and certifications related to Gold Finger PCBs from Gold Finger PCB Manufacturer, shedding light on why compliance is imperative in industries where precision and quality are paramount.

Understanding Gold Finger PCBs

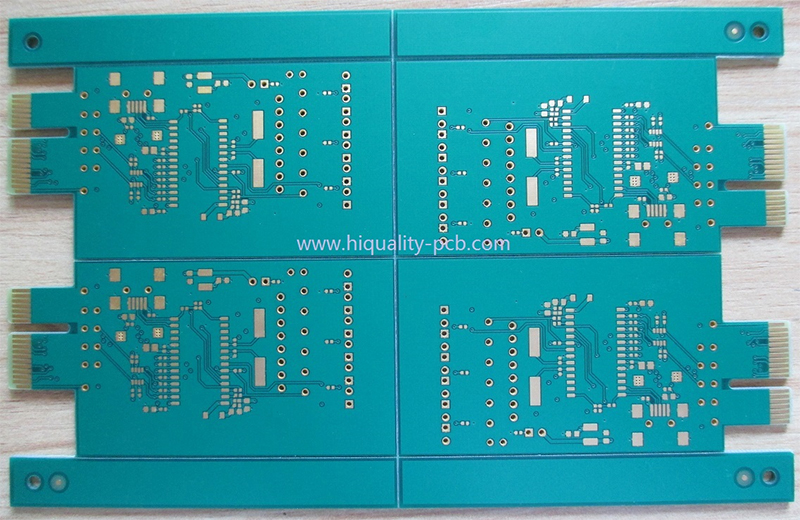

Before we delve into the regulatory intricacies, let's first understand what Gold Finger PCBs are and why they are prized in various industries. Gold Finger PCBs are specialized printed circuit boards designed with gold-plated contacts at their edges. These gold-plated connectors serve as the interface between a PCB and other electronic components, such as connectors or edge connectors on devices like graphics cards or memory modules.

The use of gold for these connectors is not merely aesthetic but serves several critical functions. Gold is an excellent conductor of electricity and does not corrode or oxidize, making it an ideal choice for ensuring reliable electrical connections over an extended period. This longevity and reliability are particularly crucial in industries that rely on complex and high-value electronics, such as aerospace, medical devices, telecommunications, and military applications.

Regulatory Requirements for Gold Finger PCBs

In industries with stringent standards, regulatory requirements are essential to ensure the safety, performance, and quality of products. Gold Finger PCBs are no exception, and they must meet specific regulations to be deemed suitable for use in these demanding applications. Here are some key regulatory requirements that Gold Finger PCBs may need to adhere to:

- RoHS (Restriction of Hazardous Substances): The RoHS directive restricts the use of hazardous substances in electrical and electronic equipment. Compliance with RoHS ensures that Gold Finger PCBs do not contain harmful substances such as lead, mercury, cadmium, and various brominated flame retardants. This regulation is crucial for environmental protection and human health.

- IPC (Association Connecting Electronics Industries): IPC standards provide guidelines for the design, manufacturing, and assembly of electronic components, including PCBs. Compliance with IPC standards ensures that Gold Finger PCBs meet industry-recognized quality and reliability benchmarks. IPC standards, such as IPC-A-600 for the acceptability of PCBs and IPC-A-610 for the acceptability of electronic assemblies, are widely used as reference documents.

- UL (Underwriters Laboratories) Certification: UL certification is often required for electronic components and devices to ensure they meet safety and performance standards. While Gold Finger PCBs themselves are not directly UL-certified, the components and devices they are used in may require UL certification. Ensuring the compatibility of Gold Finger PCBs with UL-certified products is essential for market access.

- ISO (International Organization for Standardization) Standards: ISO standards, particularly ISO 9001 (Quality Management System) and ISO 13485 (Medical devices - Quality Management System), are critical for industries like aerospace and medical devices. ISO certification indicates that a manufacturer follows rigorous quality control processes, which can be especially important when Gold Finger PCBs are used in applications where failure is not an option.

- Military and Aerospace Standards: For applications in the military and aerospace sectors, Gold Finger PCBs must adhere to specific standards set by organizations like the Department of Defense (DoD) and the National Aeronautics and Space Administration (NASA). These standards encompass a wide range of requirements, from reliability and ruggedness to environmental resilience.

Certifications for Gold Finger PCBs

Meeting regulatory requirements is a significant step, but obtaining certifications specific to Gold Finger PCBs can further demonstrate compliance and product quality. Here are some certifications that are relevant to Gold Finger PCBs:

- IPC Certification: IPC offers various certification programs that cover different aspects of PCB design, manufacturing, and assembly. For Gold Finger PCBs, IPC-A-600 and IPC-A-610 certification can be particularly relevant for personnel involved in quality control, inspection, and manufacturing.

- ISO 9001 Certification: ISO 9001 certification is a globally recognized standard for quality management systems. Obtaining ISO 9001 certification for the manufacturing process of Gold Finger PCBs can enhance credibility and assure customers of consistent quality.

- UL Recognition: While Gold Finger PCBs themselves may not be UL-certified, manufacturers can seek UL recognition for their PCB materials and processes. This recognition ensures that the PCBs are produced using UL-recognized materials and processes, which can facilitate the overall UL certification of end products.

- ITAR (International Traffic in Arms Regulations) Compliance: In the United States, companies involved in the defense and aerospace industries must comply with ITAR regulations, which control the export and import of defense-related articles and services. Gold Finger PCB Manufacturer must adhere to ITAR requirements.

- Medical Device Certifications: For Gold Finger PCBs used in medical devices, complying with certifications such as ISO 13485 is crucial. This certification demonstrates the manufacturer's commitment to maintaining the highest quality standards in medical device production.

Benefits of Compliance

Compliance with regulatory requirements and certifications for Gold Finger PCBs offers several tangible benefits:

- Market Access: Compliance allows manufacturers to access and compete in markets that demand high-quality and reliable electronic components. Non-compliance can result in products being rejected or banned from these markets.

- Customer Trust: Meeting regulatory and certification standards instills confidence in customers, assuring them of the product's safety, quality, and performance. This trust can lead to long-lasting business relationships.

- Risk Mitigation: Compliance helps mitigate the risk of product failures, recalls, and legal issues, which can be costly and damaging to a company's reputation.

- Continuous Improvement: Certification processes often require companies to implement and maintain robust quality management systems. These systems promote continuous improvement in manufacturing processes, leading to better products and customer satisfaction.

Conclusion

Gold Finger PCBs are the unsung heroes of many industries that demand uncompromising quality and reliability. To ensure these crucial components meet the rigorous standards of such industries, compliance with regulatory requirements and certifications is imperative. From RoHS and IPC standards to ISO certifications and industry-specific requirements, Gold Finger PCB manufacturers must navigate a complex landscape to produce components that meet the highest standards.

In today's interconnected world, where electronics power innovation across a spectrum of applications, the importance of Gold Finger PCBs cannot be overstated. By adhering to regulatory requirements and obtaining relevant certifications, Gold Finger PCB Manufacturer can contribute to the success and safety of industries with stringent standards, fostering trust among customers and ensuring the continued reliability of electronic devices that have become an integral part of our lives.