Ceramic Substrates Applications You Must Know

Keywords: Ceramic substrate

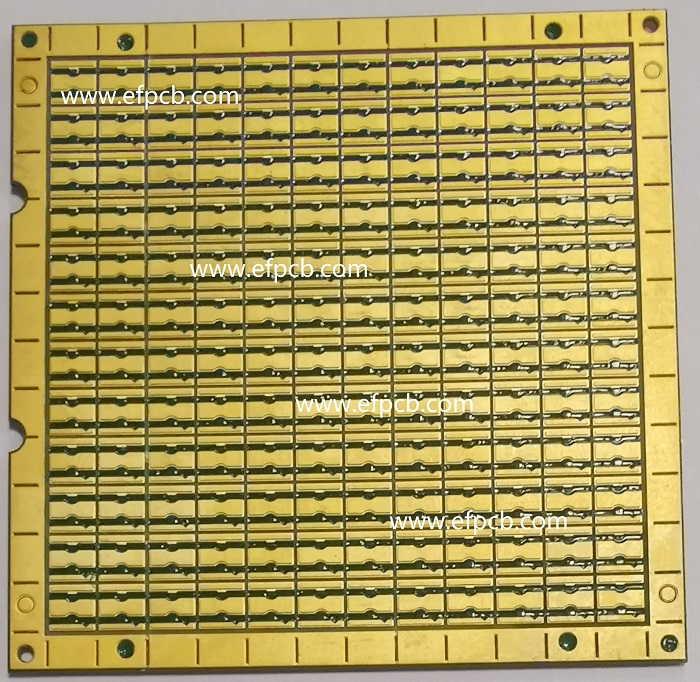

In a power electronics circuit, a Ceramic substrate is often found within the copper/metal layers of a power module. They help a PCB accomplish its intended job as effectively as possible by performing a comparable function.

Selecting a ceramic substrate over others made of metal or plastic has various benefits. Superior thermal characteristics, including strong heat conductivity, increased thermal spreading, and prolonged heat capacity, are provided by ceramic substrates. They are ideal for the most demanding applications because of their low coefficient of thermal expansion, which also provides several mechanical advantages. Additionally, they offer sturdy electrical insulation to shield people from the electrical system.

Ceramic Substrates: Applications

Hybrid and Electric Vehicles

The advancements in vehicle electrification are the reason for many changes to the comfort and safety aspects of automobiles. To satisfy rising consumer demand for low-emissions automobiles, automakers are also particularly interested in electrifying car powertrains from mild hybrid to fully electric vehicles.

More electricity is needed as electrification increases. To drive these new electric features within rigorous mechanical constraints, high-current, high-voltage solutions are required. Due to their exceptional qualities, these substrates are used in a variety of market applications, such as LED lighting, alternators; integrated starter alternators; diesel and water pump controls, motor and engine controls, converters/inverters for HEV/EV, and electric power steering and braking systems.

Alternative Energy

In the renewable energy sector, these substrates are utilized in a variety of technologies for the generation and storage of wind and solar energy, including inverters for PV (photovoltaic) and wind energy as well as concentrators for concentrator PV (CPV).

Industrial

These substrates have demonstrated good performance in a variety of settings covered by the general industry. Pump controls, variable frequency drives, traction drives, power supplies, coolers, specialized motor controllers, standardized semiconductor modules with a chip on board, DC/DC converters, and AC/DC converters are a few industrial uses for ceramic substrates.

Big-ticket home appliances

Customer preferences for energy efficiency, noise control, maintenance accessibility, and safety features affect the demand for big electrical household equipment. The clever power modules that power appliance motors are only used for Ceramic substrate in large household appliances.