Ceramic Printed Circuit Boards Varieties You Must Know

Keywords: Ceramic Substrate , Ceramic PCB

Alumina, aluminum nitride, and beryllium oxide make up the fired base material of Artistic PCB, which have high intensity conductivity. They can scatter heat quick all through the entire surface, eliminating it from problem areas.

Artistic printed circuit board types

In view of the assembling strategy, three sorts of ceramic PCBs are recognized.

• Artistic PCB for High Temperature

• Fired PCB for Low Temperature

• Fired PCB with a thick film

• Fired Printed Circuit Sheets for High Temperature

This sort of PCB, otherwise called a high-temperature co-terminated earthenware (HTCC) circuit, is made to endure high temperatures. These circuit sheets are made unmistakably. The strategy joins dissolvable, plasticizer, glue, aluminum oxide, and oil to create new pottery.

The recently made fired is covered after improvement and afterward circuit following on molybdenum or tungsten metals is utilized. After cover, the circuits will next go through a 48-hour baking interaction somewhere in the range of 1600 and 1700 degrees Celsius.

Artistic printed circuit sheets with low temperatures

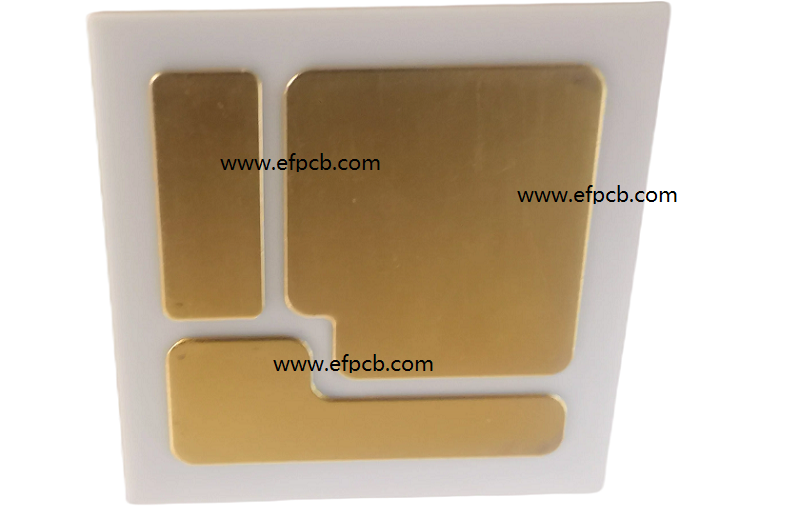

This sort of PCB, otherwise called a low-temperature co-terminated ceramic (LTTC) circuit, is made for low temperatures. The development of low-temperature earthenware PCBs is unmistakable from that of high-temperature or HTCC types. The low-temperature fired PCB is made utilizing sticky material and gem glass. The gold glue is utilized to apply both of these substances to a metal sheet. The board will then be cut and covered after that. At long last, a vaporous stove will keep a temperature of 900 degrees Celsius for the Earthenware Substrate

Better psychologist resilience and diminished war page might be tracked down in low-temperature artistic PCBs. Taking everything into account, LTTC will have more mechanical force and warm conductivity than different assortments, including HTCCs. While working with sans heat things like Drove lights, the low-temperature PCB is ideal because of its warm advantage.

Ceramic printed circuit sheets with a thick film

This kind of PCB is made by covering fired base material with dielectric and gold glues. The material will be heated at a temperature of 1000 °C or lower subsequent to being covered with any of these glues. It is desirable over utilize thick layer fired on the grounds that it keeps copper from oxidizing. As a result, an electrical capacitor, resistor, transmitter, semiconductor, and channel may be generally exchanged while making a clay PCB. This sort is utilized by makers that are stressed over oxidation.