Benefits of Rigid-Flex PCB

Keywords: Rigid Flexible PCB Manufacturer, Rigid Flex PCB

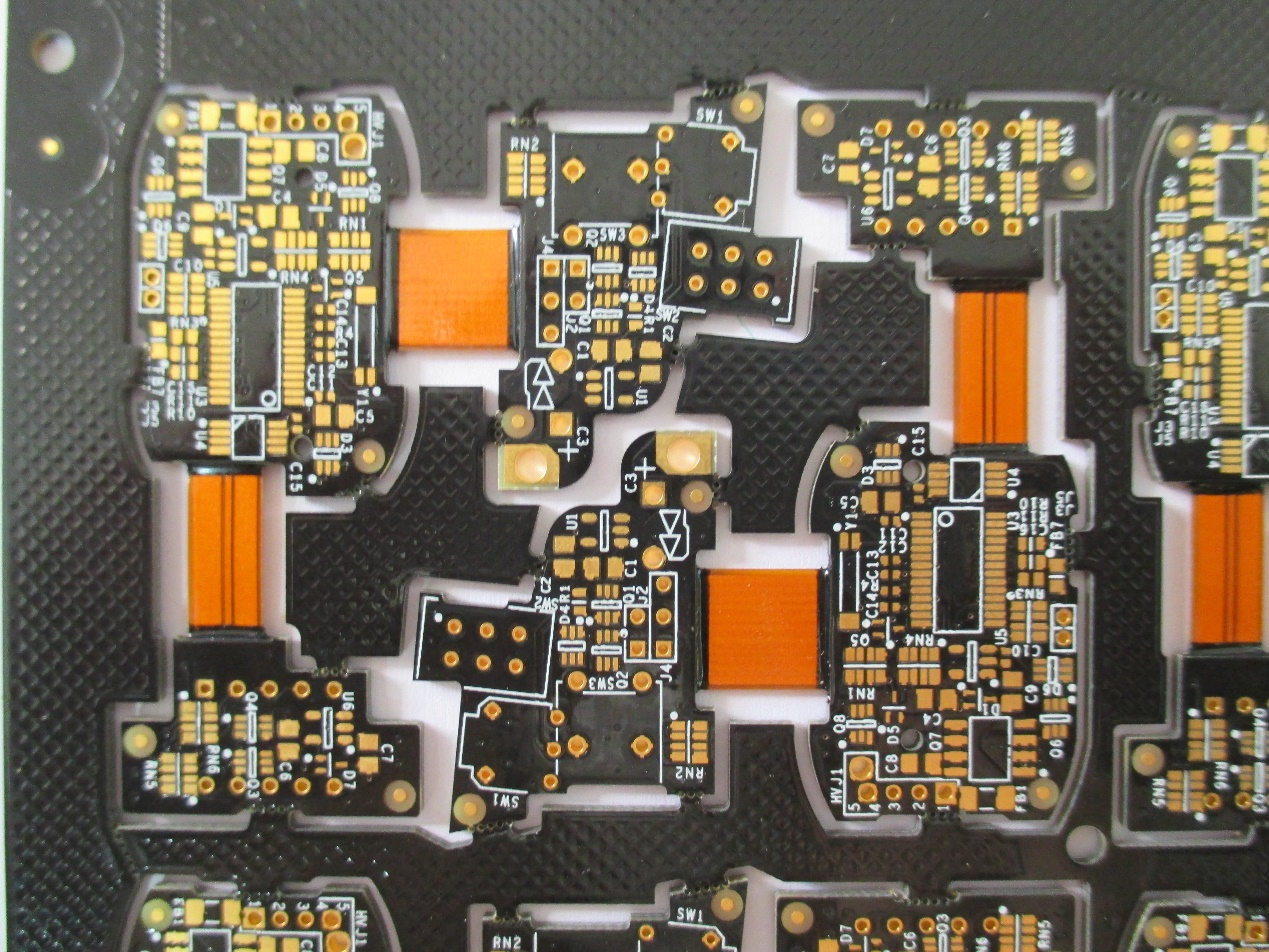

Rigid Flexible PCB is a half and half circuit board that integrates parts from inflexible and adaptable circuit sheets, making a board that might be collapsed or persistently flexed. During the assembling system, the board is frequently framed into a flexed shape or bend. The adaptable piece of the board is frequently used for associations between inflexible sheets, empowering more modest, more space-effective sheets with smaller guide lines. As connectors are regularly pointless when adaptable PCBs are utilized for network, unbending flex printed circuit sheets become fundamentally lighter. Since these sheets might be collapsed or turned to make the legitimate shape for the item, unbending flex PCB plans are somewhat more challenging to make. More prominent spatial execution might be accomplished by planning a board in three aspects, which can then be applied in special circumstances where weight and space decrease are required, like in clinical hardware.

Adaptable circuit substrates and firm circuit substrates are reinforced together in an unbending flex PCB. By utilizing high-malleability electrodeposited or moved toughened copper conduits that are photograph carved onto an adaptable protecting film, unbending flex PCBs go past the constraints of regular inflexible PCBs and utilize the exceptional characteristics of flex circuits.

Adaptable polyimide materials, like Kapton or Norton, and copper are fortified together in flex circuits under tension, intensity, and acrylic stick. You might introduce parts on the two sides of the unbending board, very much like with ordinary PCBs. An inflexible flex configuration doesn't use connectors or interfacing wires between the parts due to the mix that happens among firm and adaptable circuits. All things considered, the framework is electrically associated by the flex circuits.

The shortfall of associations and interfacing links in Unbending Adaptable PCB Producer accomplishes the accompanying objectives:

• expands the circuit's ability for signal transmission without misfortune

• considers managed impedance

• eliminates association issues like crisp joints

• diminishes weight

• accounts for additional parts

Smaller plan capacities and negligible weight pursue unbending flex sheets a decent decision for various applications in the aviation, clinical, and buyer hardware businesses.

Benefits of 360-degree bendable inflexible flex PCBs

• diminished space request thanks to 3D abilities

• Shock resilience

• further developed constancy

• Low in weight

• Higher association dependability is guaranteed with less patch joints.

• PCB gathering systems simplified

Wide scopes of complex plan blends are presently conceivable due to enhancements in unbending flex circuit board materials, stack-ups, and structures. With these other options, there are enormous chances to increment bundle thickness and plan coordination inside a specific plan of Inflexible Flex PCB.