Benefits of Multilayer PCB

Keyword: Multilayer PCB

Most of present day hardware are based on printed circuit sheets (PCBs), which decide principal capabilities by consolidating parts and wiring procedures. Most of PCBs from prior times were exceptionally clear and compelled by assembling strategies, however PCBs from today are altogether more muddled. In the present gadgets industry, PCBs are essentially more expanded, going from state of the art adaptable options in contrast to odd-molded types. Multilayer PCB, be that as it may, is especially popular.

While more intricate gadgets, similar to PC motherboards, frequently have various layers, less difficult hardware with less capabilities ordinarily have a solitary layer of PCBs. These are Multilayer PCBs, as the name proposes. These Multilayer PCBs are presently more normal than any time in recent memory, and they might be made more modest thanks to headways in assembling innovation and the intricacy of current hardware.

Keep perusing to figure out more about Multilayer PCBs, their applications, and their advantages in the field of contemporary gadgets.

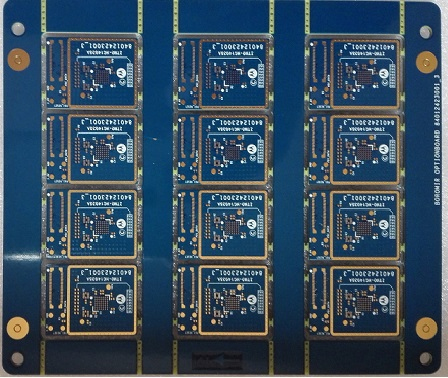

A Multilayer PCB

A PCB that is developed with at least three conductive copper foil layers is alluded to as a Multilayer PCB. These look like some twofold sided circuit board layers that have been overlaid, reinforced, and isolated by layers of intensity safe protection. Two layers are placed on the PCB's surface sides to connection to the climate during the total development. Vias, like plated through openings, blinds, and covered vias, are utilized to give all electrical associations between the layers. The utilization of this procedure prompts the development of extraordinarily complex PCBs in a scope of sizes.

The Multilayer PCB was made because of the hardware business' continuous progressions. Electronic capabilities have advanced over the course of time, turning out to be more convoluted and requiring progressively complex PCBs. PCBs were sadly obliged by issues like clamor, stray capacitance, and crosstalk, requiring the recognition of specific plan limitations. Because of these plan factors, it was trying to get a satisfactory degree of execution from a solitary sided or even twofold sided PCB; subsequently, the Multilayer PCB was made.

Because of the way that they give twofold layer PCB power in an extensively more modest size, Multilayer PCBs are turning out to be increasingly more typical in hardware. To fulfill the needs of their developing purposes, they are accessible in various shapes and sizes with thicknesses going from four to twelve layers. Since odd quantities of layers could create issues in the circuit like twisting and are not more financially savvy to manufacture, even quantities of layers are frequently utilized.

Multilayer PCBs are turning into a basic part of contemporary innovation, despite the fact that they are many times more costly and work serious to make. This is huge on the grounds that they have a large number of benefits over single-and twofold layer variations.

Advantages of Multilayer PCBs

According to a mechanical viewpoint, Multilayer PCB gives a few plan benefits. These advantages Multilayer PCBs give include:

• Little Size: Multilayer PCBs' little size is quite possibly of its most prominent and acclaimed advantage. Because of their layered plan, Multilayer PCBs are innately more modest than traditional PCBs with comparable usefulness. As the latest thing is toward more modest, more versatile, yet more impressive innovation like cell phones, workstations, tablets, and wearables, current gadgets will significantly profit from this.

• Lightweight Plan: A multifaceted plan takes out the requirement for some connectors expected to interconnect separate single and twofold layered PCBs, coming about in more modest PCBs that are lighter in weight. Once more, this is favorable for contemporary gadgets, which are more situated on movability.

• Superior grade: Multilayer PCBs are frequently of greater than single-and twofold layer PCBs on account of the broad work and arranging expected to make them. Subsequently, they every now and again become more reliable.

• Upgraded Toughness: Multilayer PCBs are many times more vigorous naturally. These Multilayer PCBs should have the option to get through the intensity and strain expected to tie them together notwithstanding their weight. Notwithstanding these components, Multilayer PCBs tie everything together utilizing prepreg holding specialists and defensive materials and utilize various degrees of protection between circuit layers.

• Expanded Adaptability: While not all Multilayer PCB gatherings fall under this classification, some utilize adaptable assembling techniques, coming about in an adaptable Multilayer PCB. For circumstances where light bowing and flexing may happen at times, this quality may be very alluring. Once more, this isn't valid for all Multilayer PCBs, and an adaptable PCB loses adaptability as additional layers are added to it.

• More Viable: Multilayer PCBs incorporate various layers into a solitary PCB, making them profoundly high-thickness gatherings. Sheets are more connective due to the lacking elbow room, and in spite of their little size, they can work at higher limits and rates thanks to their natural electrical properties.

• Single Association Point: Dissimilar to other PCB parts, Multilayer PCBs are made to work as a solitary unit. They just have one association point as an outcome, rather than the few association focuses expected to utilize various single-layer PCBs. Since there is only one associating point expected in the completed item, this likewise works to the advantage of planners of electrical items. This is particularly invaluable for little gadgets and gadgets made to be light and conservative.

Multilayer PCBs give benefits over single-layer options.

The advantages of Multilayer PCBs are substantially clearer when contrasted with single-layer substitutes. Coming up next are a portion of the fundamental improvements Multilayer PCBs give:

• Higher Gathering Thickness: Multilayer PCBs have an expanded thickness due to stacking, however single-layer PCBs' thickness is obliged by their surface region. Notwithstanding the diminished PCB impression, the expanded thickness empowers more noteworthy usefulness, improving limit and speed.

• More modest by and large Size: Contrasted with single-layer PCBs, Multilayer PCBs are frequently more modest. Multilayer PCBs upgrade surface region with the expansion of layers, yet single-layer PCBs should extend the circuit's size to increment surface region. Subsequently, higher-limit single-layer PCBs must be used in greater merchandise, while higher-limit Multilayer PCBs might be utilized in more modest gadgets.

• Lighter Weight: Since parts are coordinated into a Multilayer PCB, less associations and different parts are required, making this a lightweight choice for unpredictable electrical applications. Multilayer PCBs might play out similar undertakings as a few single-layer PCBs, yet they do as such in a more modest space and with less interfacing parts, bringing about a lighter board. This is a critical element to consider for more modest gadgets when weight is an issue.

• More Utilitarian Plan: as a rule, Multilayer PCBs have more potential than the normal single-layer PCB. Multilayer PCBs might accomplish more in spite of being more modest and lighter due to the expanded utilization of controlled impedance highlights, more EMI protecting, and generally speaking upgraded plan quality.

Generally, a Multilayer PCB is likely your most ideal choice to make a conservative, lightweight, modern contraption where quality is significant. Be that as it may, a solitary or two-layer PCB configuration might be more financially savvy on the off chance that size and weight are not the principal plan contemplations for your gadget.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact