Benefits, Best Resources, and Prototype of Printed Circuit Boards

Keywords: Printed Circuit Board Manufacturer, PCB Manufacturer, PCB Manufacturing

Vacuum tubes fulfilled a comparable function long before printed circuit boards (PCBs) entered the scene. In the simplest words, PCBs from Printed Circuit Board Manufacturer are used to connect electrical product components simply and affordably.

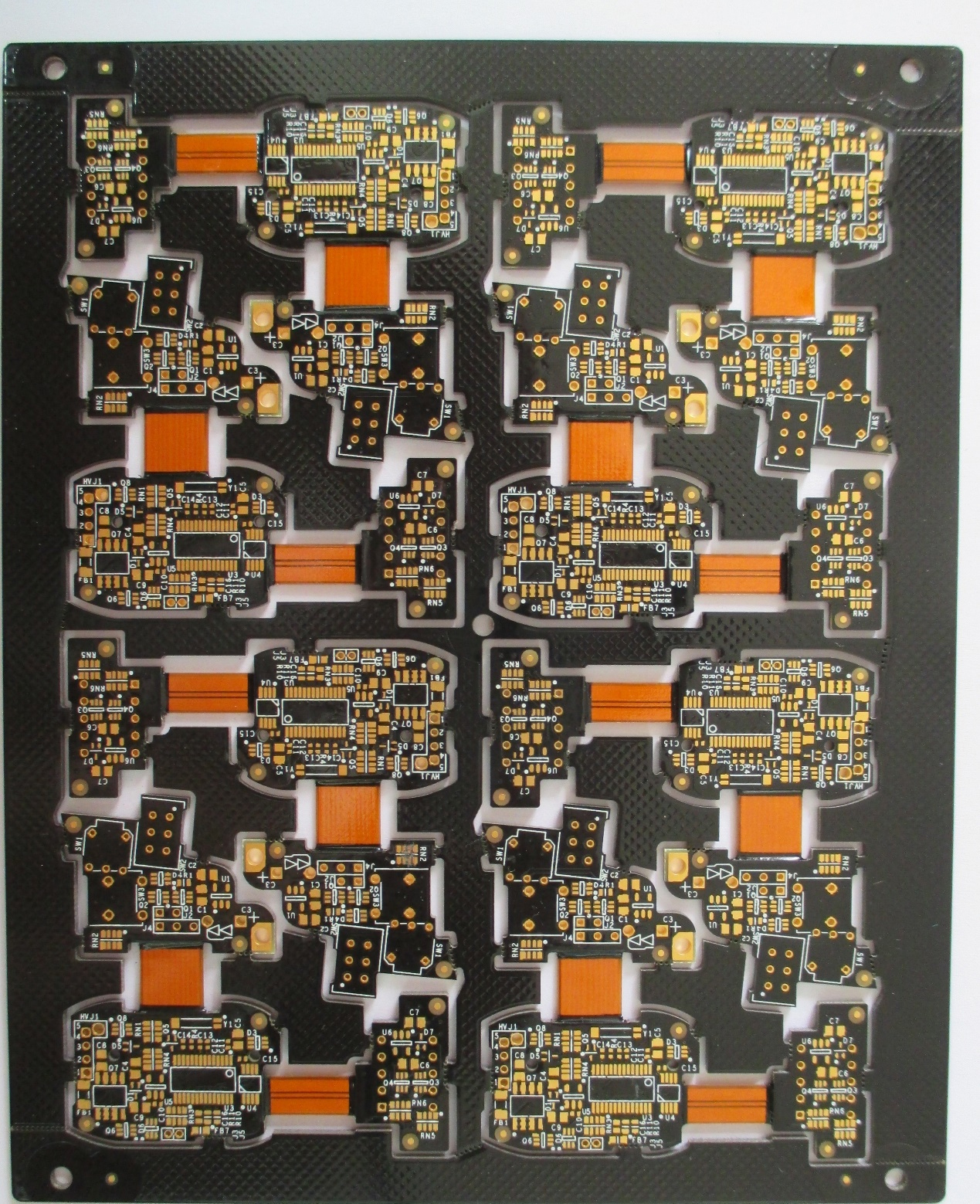

Typically, PCBs are constructed from an insulating substance with a metal surface coating on both the bottom and top. If you look at a standard printed circuit board (PCB), you will notice acid-etched surface patterns that are there to establish an electrical channel. The etching make sure that all of the parts interact with one another as planned. The finished item is made by soldering the components to the surface. This succinct explanation makes it simple to comprehend why PCBs are so useful and important in the field of electronics.

The Benefits

Electronic circuits may now be more compact and smaller thanks to PCBs from the PCB Manufacturer. A PCB may be found in practically every gadget nowadays. The motherboard is the primary printed circuit board of a computer. On certain circuit boards, there are additional extra drilling and holes that are designed to accommodate the use of capacitors and other components.

The Best Resources

Typically, manufacturers get their products from reputable vendors like Rogers. Rogers materials have excellent microwave performance and may be used to fabricate FR-4. These also have strong thermal conductivity, which is far superior to some of the other PTFE materials that are typically used for heat management.

Obtaining prototype printed circuit boards

Companies and electrical brands typically order more than one PCB. They need to make a prototype to fulfill a sizable order. To guarantee that the desired features and benefits are realized, a PCB prototype is the first one that is manufactured and tested at all levels before PCB Manufacturing. A printed circuit board prototype may be completed by manufacturers with the required knowledge and experience in less than a week. The prototype is submitted for production when it has been completed, tested, and received the client's approval. The printed circuit boards that are created are by the manufacturing specifications, although they are often inspected individually before being sent out.