An Overview of Multilayer PCB Design and Alignment Control

Keywords: FR4 PCB, Multilayer PCB

Setup and Preparation

For a Multilayer PCB design, older legacy PCB footprints may not be adequate in some cases and you need to find out if there are any essential additional requirements. You may have to add attributes or layers to a footprint for multilayer use based on the CAD system being used. Here is where it be a real benefit to have access to a more advanced PCB design system linking to online library services. Having the most accurate and latest PCB footprint source data to work with becomes much easier.

Planning your layer stack up will depict the main difference between a multilayer and double layer board setup. While planning your board layer stack up, the following are some of the points that you will need to consider:

- Cost: the overall cost of building the board will be affected by the layer count, fabrication materials as well as configuration. To consider all of the options, you need to work with your manufacturer here.

- Performance: a difference in the materials that the board will be fabricated with is made by the operating environment of the final board and how fast the circuitry will operate. Based on what the needs are, there are more advanced materials that may be better suited for your application As compared to FR-4. But parameters such as your impedance calculations may get affected by those materials. However, the FR4 PCB is also reliable. Here is where an invaluable source of information will be the help of your PCB manufacturer.

- Circuitry: To create the most optimum layer configuration, you also need to understand the needs of your circuitry. Adding additional ground planes, a strip line layer configuration may be needed for sensitive signals may require for their best performance. With their ground planes, Areas of digital and analog circuitry will need to be separated. Isolation is needed by onboard power supplies. This should be planned for before the layout starts, and all of this could affect the layer configuration.

- Density: when determining the configuration of your board layer stack up, the routing density of your board is another factor. After you’ve already started your layout, it is very painful when you have to add layers by going back to a board design. You may have to make a lot of changes to your layout apart from having to reconfigure your CAD database. You will be paying more for the boards than you should if you start with too many layers on the other hand.

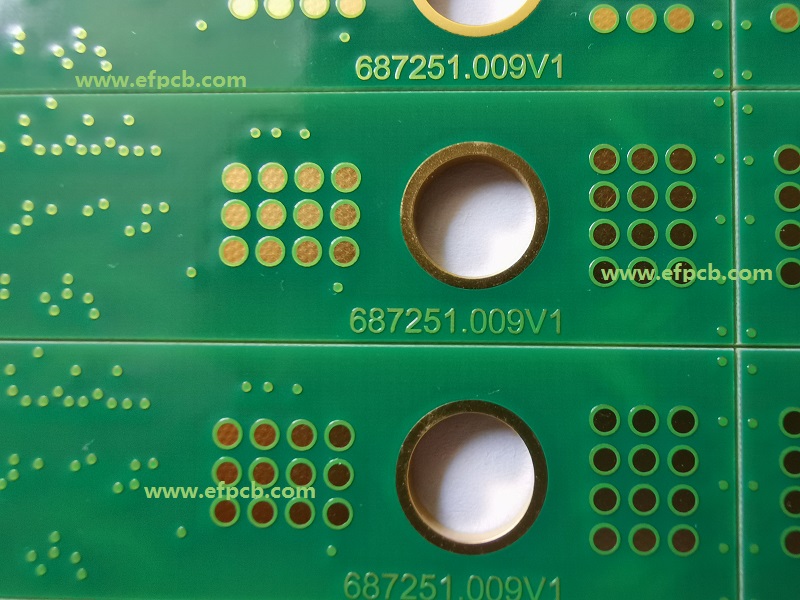

Multilayer PCB Alignment Control

Fabrication of Multilayer PCB, especially when many layers are involved on a small size board, is a very tough process. We are required to fit more components per square inch than ever before - dictated by the ergonomics features that the consumer expects as the gadgets are getting smaller and smaller. Circuit assembly is a huge challenge. We can be faced with problems when the layers have to come together although it is relatively easy to design an electronic scheme by using modern computer software and print it through advanced etching techniques.

The whole system will fail to work if the copper sheets are not aligned perfectly because the wrong points will come into contact or the current won't flow between the sheets. Malfunctioning of the circuit may occur if the design effort is reduced.

Mechanical contact methods to align layers were earlier used by the manufacturers of multilayer PCBs. Now it is very easier. For aligning the top of the layer to the bottom, it is possible to use cameras with imaging systems and they can be positioned to fit properly if imprecision is detected.

The so-called Perfect Test system is being adopted by many manufacturers gradually to achieve a top precision layer alignment. The actual position of each inner sheet to 0.001-inch accuracy is determined by it. The average design clearance between the holes and pattern that connect the sheets is determined by the test system by testing a certain number of prototype printed circuit boards. The results are processed and then the system will give you high precision multilayer and have calculated the best alignment PCB products that you'll be proud of when you start the actual production process.

Towards a superior product, Getting the prototype spot on is a huge step. To get through this important stage of production as fast as they can, many manufacturers try, unfortunately. The aforementioned methods are essential but they are not cheap.

What to use must be considered by each electronics company trying to improve or start their quality control to make sure their product stands out. The best quality always wins in the long run as the competition in the electronics sector is fierce.

Multilayer PCB Placing and Routing

It will be a joy to work with internal power planes and trace routing, but there are some important considerations at the same time here as well:

- Some routing must be routed on layers adjacent to ground planes and will require a stripline layer structure. To help reduce any possible broadside crosstalk or coupling, sensitive routing must be crossed perpendicularly on adjacent internal signal layers additionally.

- You must plan for it as more components will be typically present in Multilayer boards and therefore more routing than a double-sided board. Some of this routing may have specific routing widths and spaces or other requirements based on the technology of the board such as impedance controlled traces or differential pairs.

- So that sensitive signals don’t ruin their return path by crossing the splits, Split planes need to be laid out. A lot of noise can be created on the board in a situation like this.

- For connectivity, Ground planes will have a lot of vias in them but signal return paths could be affected by those vias. To avoid blocking up the planes, this requires careful planning of your routing.

Design with Output Files and Documentation Finalizing

You will need to create the same type of documentation that you’ve always created to get your multilayer design out for manufacturing but with a few exceptions. On your manufacturing drawings, there will be more details needed first of all. Your fabrication drawing will need notes detailing the specifics of how the board will be built, and a multilayer board stack-up detail. Second, you will need to generate additional files for the multiple board layers if you are using Gerber files for your manufacturing outputs. In managing and creating your manufacturing output files, using an advanced set of CAD tools can be very helpful here in Multilayer PCB.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact