All About HDI and the HDI PCB Manufacturing

Keywords; HDI PCB Manufacturing, High Volume PCB

Keywords; HDI PCB Manufacturing, High Volume PCB

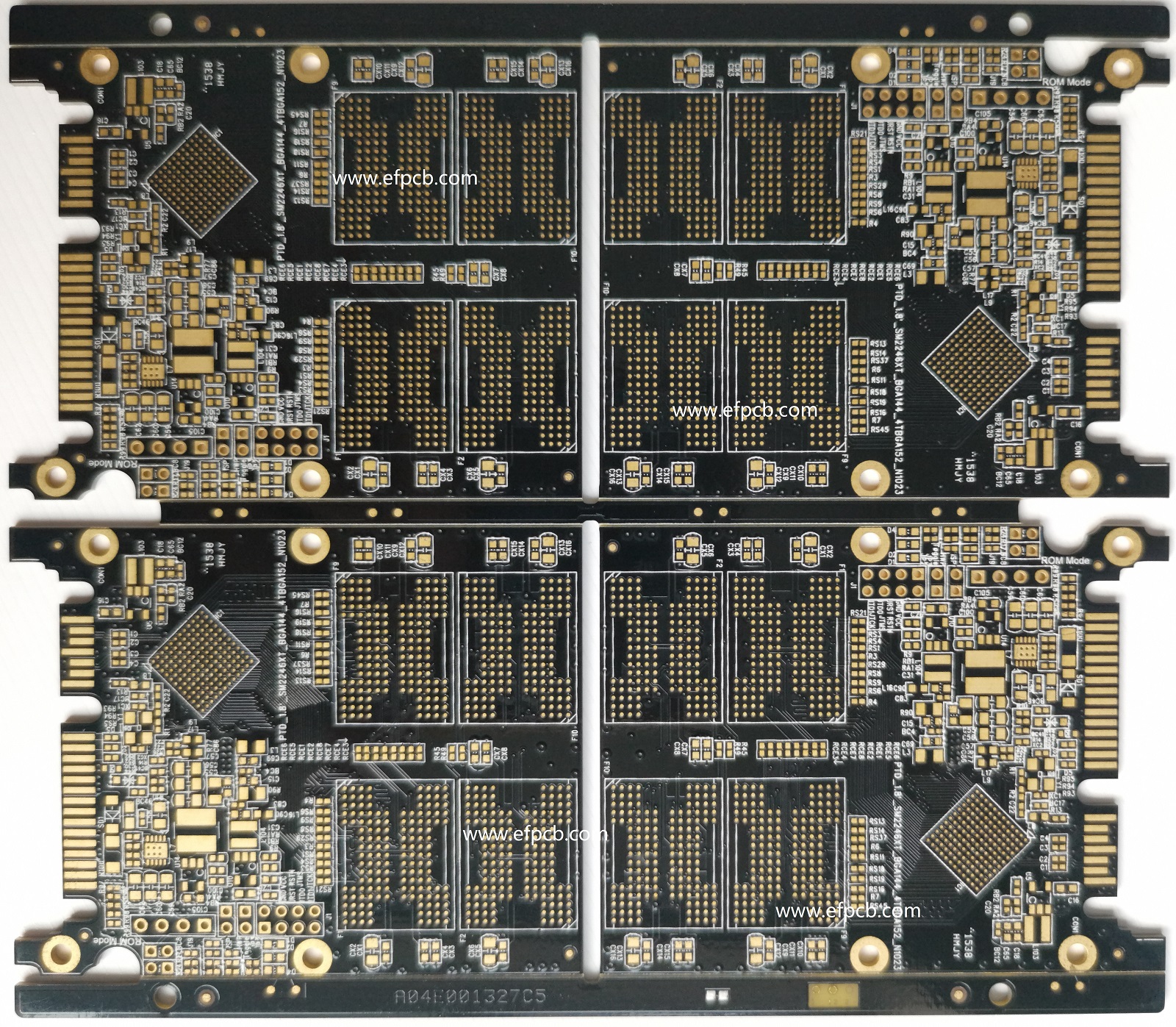

With the advancement of world of technology, the need to pack more capabilities into smaller packages has also evolved. Using HDI PCB Manufacturing techniques the designing of PCBs is done which tend to be smaller as more components are packed in a smaller space. To pack more components into a smaller area an HDI PCB uses blind, buried, and micro vias, vias in pads, and very thin traces.

When researchers started investigating ways to reduce the size of vias in PCBs, the high-density interconnect (HDI) printed circuit design and fabrication started in 1980.In 1984 the first production build-up or sequential printed boards appeared. Ever since that time, component manufacturers always look for ways to pack more functions no matter whether it is on a single chip or a single board designers and. Today, in the IPC-2315, IPC-2226, IPC-4104, and IPC-6016 standards HDI design and fabrication are codified.

There are some design and manufacturing challenges to overcome while planning an HDI PCB design. While designing an HDI PCB here is a short list of challenges you may find:

There are larger number of components on both sides of PCB stack up

Limited board workspace area

Longer trace routes creates much longer signal flight times

To complete the board requirement of more trace routes

Tighter spacing and smaller components

You can violate the normal rules in High Volume PCB and create powerful PCBs with very high interconnect density only with the right set of layout and routing tools built on a rules-driven design engine. When you use advanced PCB design software that is built for HDI PCB design working with high-density PCB routing and fine pitch components is easy.

Difference in HDI PCB Design and Manufacturing

From the traditional PCB manufacturing process, the HDI manufacturing process differs in a few simple yet important ways. Major point here is that fabricator limitations will constrain design freedom. It even sets the limits as to how the board can be routed. If you want to accommodate design for manufacturing (DFM) requirements then it clearly indicates taking advantage of automation in your design software. On the HDI PCB Manufacturing process the exact DFM requirements depend and materials used to build the board. When we consider reliability requirements DFM requirements also become important.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 Flexible PCB Factories in 2025

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact